Method for increasing utilization value of mixed C4

A technology of mixing C4 and its value, which is applied in the processing of gas mixtures, treating hydrocarbon oil, organic chemistry, etc., can solve the problems of effective utilization of non-butadiene components, effective utilization of C4 not involved in refineries, etc., to achieve The effect of increasing economy, improving utilization rate and increasing ethylene production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

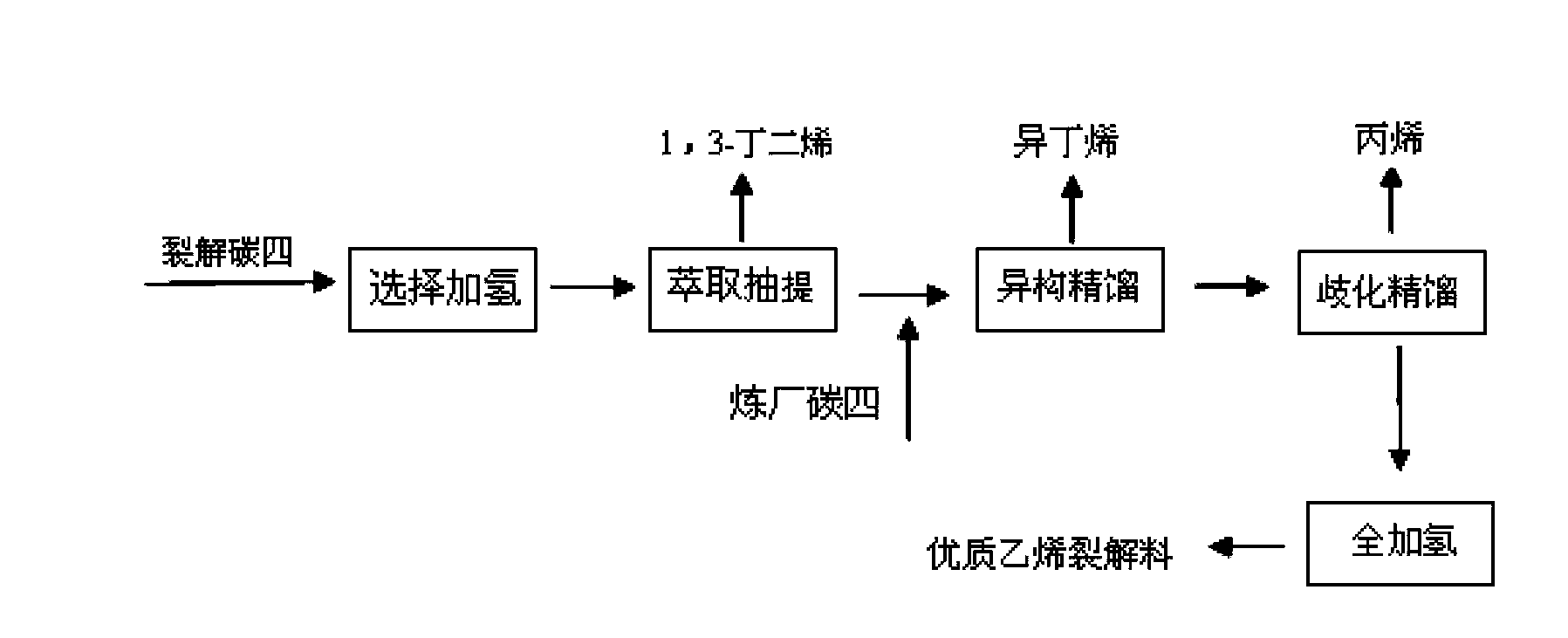

[0031] according to figure 1 As shown, the cracking mixed carbon four composition (weight %) is: butadiene: 55.0%, isobutene: 20%, 1-butene: 13%, 2-butene: 7%, n-butane: 2.5%, isobutene Butane: 1%, butyne: 1.5%. Using the process of the present invention, the selective hydrogenation and alkyne removal reaction catalyst is aluminum oxide supported metal palladium, the molar ratio of hydrogen to alkyne in the reaction feed is 2:1, the reaction feed temperature is 30°C, the reaction pressure is 1.0MPa, and the reaction feed volume Airspeed is 5.0h -1 ; The hydrogenation reaction product is extracted and rectified system, wherein the main washing tower is composed of packing and floating valve, the rectifying separation tower is a packed tower, the pressure at the top of the main washing tower is controlled at 390±20Kpa, and the sixth layer of packing 1,3 - The mass percentage of butadiene is controlled at 40-55%, the amount of 1,3-butadiene in the overhead raffinate is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com