Liquefied natural gas forced gasification system

A technology for liquefied natural gas and gasification system, which is applied in the field of liquefied natural gas (LNG) forced gasification system, can solve the problems of consuming thermal energy or electric energy, high cost of submersible pumps and high manufacturing cost, and achieves energy saving, simple structure, Use safe and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

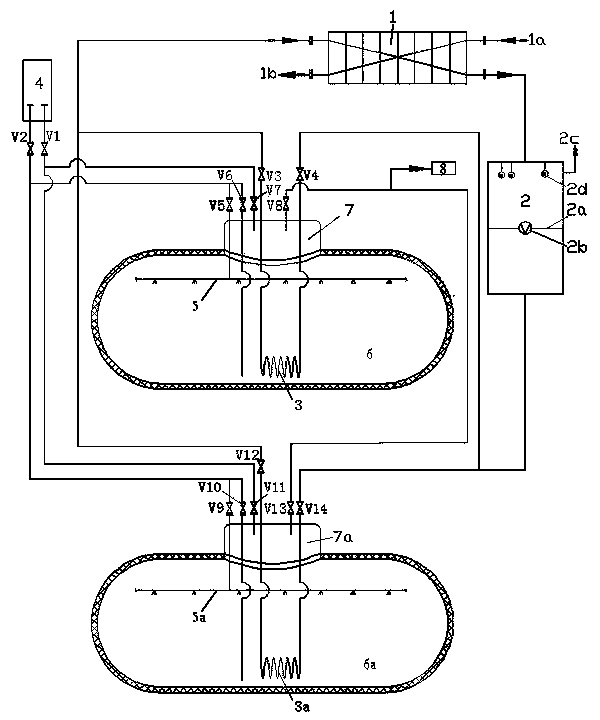

[0014] figure 1 A structural diagram of a forced gasification system for liquefied natural gas is shown. In the figure, the LNG forced gasification system is equipped with an LNG storage tank gas chamber on the LNG storage tank, and a heating coil is installed in the LNG storage tank, and the heating coil is connected in series with the heat exchanger 1 and the nitrogen buffer tank 2 through pipelines , A partition 2a is set in the nitrogen buffer tank 2, and a nitrogen circulation blower 2b is set on the partition 2a. The nitrogen buffer tank 2 is provided with a pressure gauge, a temperature gauge and a combustible gas detector 2d.

[0015] figure 1 As shown, the two storage tank heating coils are respectively arranged in two parallel-connected LNG storage tanks in a parallel connection manner. The first LNG storage tank 6 is provided with a first heating coil 3 and a first spray pipeline 5 , and the upper part of the first LNG storage tank 6 is a first LNG storage tank g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com