Technology for planting straw mushroom by taking sisal hemp slag as raw material

A technology of sisal dregs and straw mushrooms, which is applied in the field of planting straw mushrooms using sisal dregs as raw materials, can solve the problems of high pesticide residues, poisonous pesticides, adverse effects, etc. Effect of growth cycle and cost reduction of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

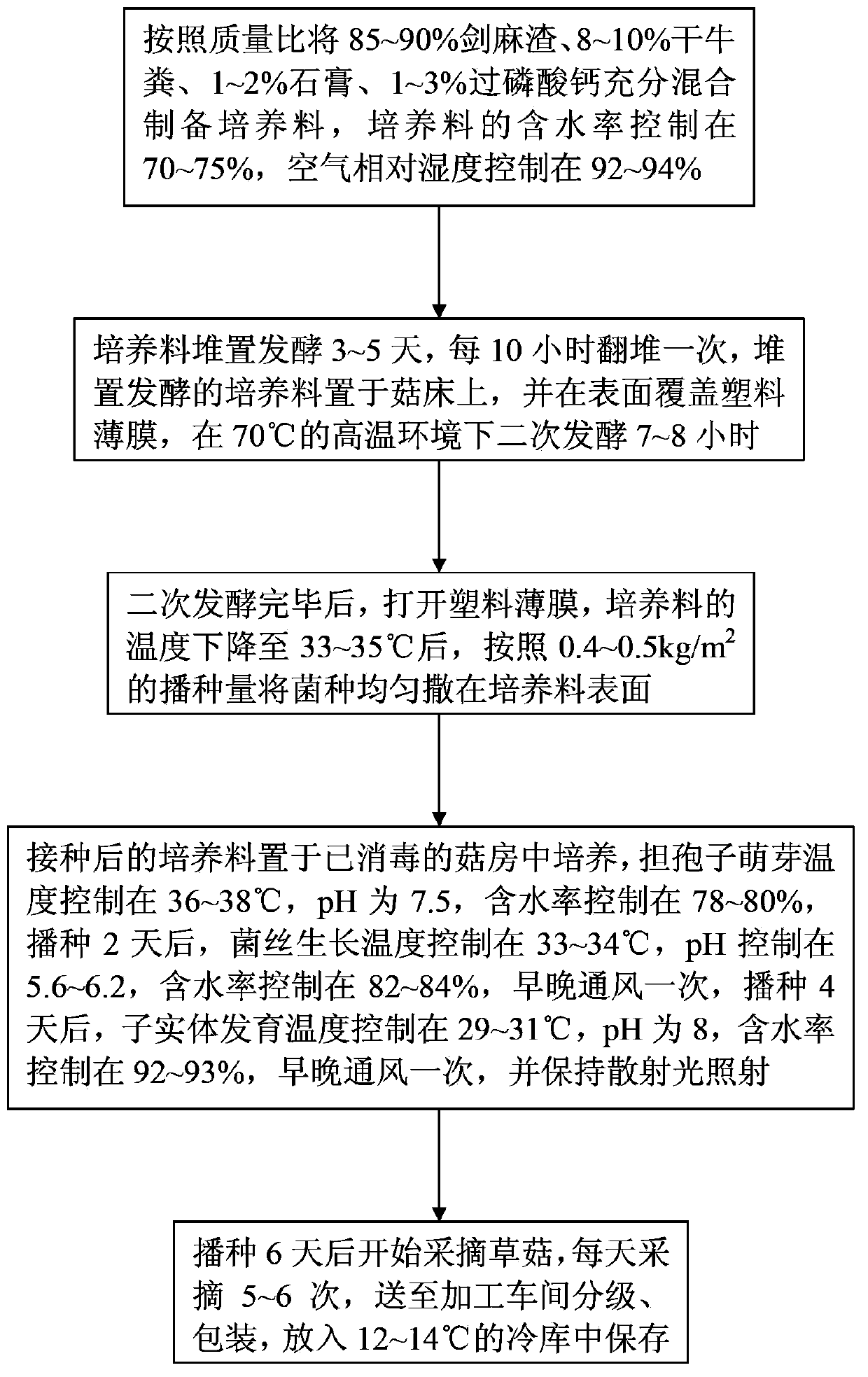

[0025] Step 1. Fully mix 88% sisal slag, 9% dry cow dung, 1.2% gypsum, and 1.8% superphosphate according to the mass ratio to prepare compost. The moisture content of the compost is controlled at 72%, and the relative air humidity is controlled at 93%. %;

[0026] Step 2: The compost is stacked and fermented for 4 days, and the compost is turned over every 10 hours. The fermented compost is placed on the mushroom bed, and the surface is covered with a plastic film, and the secondary fermentation is carried out at a high temperature of 70°C for 7 hours;

[0027] Step 3: After the secondary fermentation is completed, open the plastic film, and after the temperature of the compost drops to 34°C, the temperature of the compost is reduced to 0.5kg / m 2 Spread the bacteria evenly on the surface of the compost;

[0028] Step 4: Place the culture material after inoculation in a sterilized mushroom house for cultivation. The germination temperature of the basidiospores is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com