Mechanical separation enriching method for wheat-bran aleuronic cells

A technology of aleurone cell and mechanical separation, applied in the field of separation and enrichment of aleurone cells, dry mechanical separation and enrichment of aleurone cells in wheat bran, which can solve the problem that the complete structure of cells is easily destroyed and reduces the nutritional value of aleurone products , nutrient loss and other issues, to achieve the effect of retaining nutritional value, aleurone cell structure integrity, and avoiding the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Drying: dry the wheat bran and control its moisture content to 10%;

[0036] (2) Pre-grinding: Use a swing-type 500g stainless steel cabin traditional Chinese medicine grinder (product of Shanghai Qijian Bingdu Electric Co., Ltd., model: Q-500B3, speed 26000 rpm) to grind the dried wheat bran in step (1) 2min, pass through a 40-mesh vibrating sieve (product of Shanghai Luda Experimental Instrument Co., Ltd., model ZBSX-92A), and take the sieve;

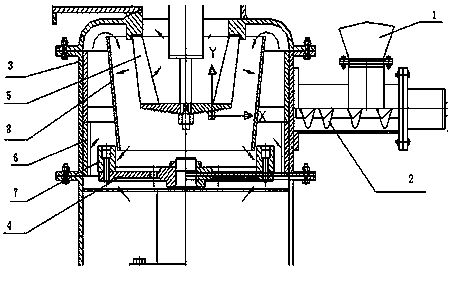

[0037] (3) Peeling and crushing: such as figure 2 As shown, the sieve obtained in step (2) is transported into a closed crushing chamber 3 through a feeding hopper 1 and a screw feeder 2 for peeling and crushing treatment. The crushing chamber 3 includes a hammer impact crushing disc 4 and a turbine classifier 5. The inner wall of the crushing chamber 3 is equipped with a lining plate with teeth, grooves or patterns 6. The diameter of the crushing disc of the hammer mill 4 is 170mm, and the number of hammer heads 7 is 4. ...

Embodiment 2

[0041] (1) Drying: dry the wheat bran and control its moisture content to 8%;

[0042] (2) Pre-crushing: use a swinging 500g stainless steel engine room traditional Chinese medicine grinder (same as Example 1) to grind the dried wheat bran in step (1) for 1 min, pass through a 40-mesh vibrating sieve (same as Example 1), and take Oversize;

[0043] (3) Peeling and crushing: the equipment used and its specific working process are the same as in Example 1, the difference is that the hammer head speed is adjusted to 40m / s, the turbine classifier 5 classification wheel speed is 2600rpm, and the feed rate is 900g / h;

[0044] (4) Screening and separation: the peeled and pulverized material obtained in step (3) is passed through a negative pressure fan (air volume 220 m 3 / h) is sent out, and collected by a cyclone separator, sieved and separated by a vibrating sieve (same as in Example 1), and a sieved sample with a particle size of 100-200 μm is taken to obtain aleurone finished p...

Embodiment 3

[0047] (1) Drying: dry the wheat bran and control its moisture content to 10%;

[0048] (2) Pre-crushing: use a swinging 500g stainless steel engine room traditional Chinese medicine grinder (same as Example 1) to grind the dried wheat bran in step (1) for 1 min, pass through a 40-mesh vibrating sieve (same as Example 1), and take Oversize;

[0049] (3) Peeling and crushing: the equipment used and its specific working process are the same as in Example 1, the difference being that the rotating speed of the hammerhead is adjusted to 35m / s, the rotating speed of the 5 classifying wheels of the turbine classifier is 3000rpm, and the feed rate is 1000g / h;

[0050] (4) Screening and separation: the peeled and pulverized material obtained in step (3) is passed through a negative pressure fan (air volume 180 m 3 / h) sent out, and collected by a cyclone separator, separated by sieve powder through a vibrating sieve (same as in Example 1), and a sieved sample with a particle size of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com