Processing method capable of recycling iron-containing sludge generated in advanced oxidation techniques

A sludge recycling and treatment method technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of occupying large land resources, refractory iron-containing sludge, waste of iron resources, etc. problems, to achieve the effect of saving drug costs, reducing costs, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

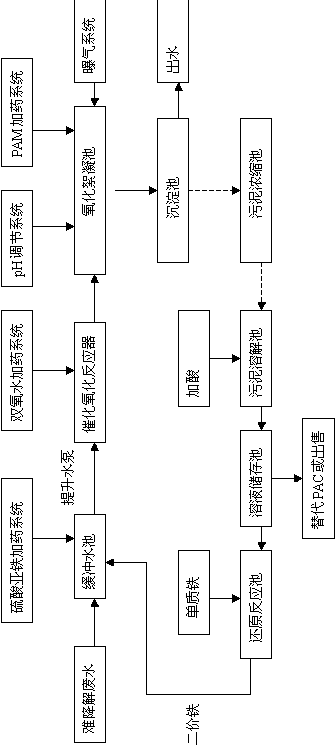

Image

Examples

Embodiment 1

[0016] Example 1: In a pulp and paper enterprise using wood as raw material, the water in the middle section passes through a biochemical system (various forms of anaerobic and aerobic processes) and the COD of the effluent is ≤ 250mg / L.

[0017] (1) The waste water enters the buffer pool by gravity, adding 1000ppm ferrous sulfate, after being mixed evenly by the impeller of the lifting pump, it enters the catalytic oxidation reactor, and at the same time, adds 100ppm hydrogen peroxide, reacts for 6 minutes, flows into the oxidation flocculation tank for 30 minutes, and adjusts the pH value by adding alkali To 7.0, add flocculant to precipitate for 5 hours, the COD of the effluent is 70mg / L, and the COD removal rate is 72%.

[0018] (2) Put the iron-containing sludge in the sludge thickening tank into the sludge dissolving tank, add a certain amount of waste hydrochloric acid, and turn on the mixer to fully dissolve the sludge to form a ferric iron solution. At this time, the p...

Embodiment 2

[0021] Example 2: Man-made fiber enterprises that use α-cellulose extracted from cellulose raw materials such as wood and plant stalks, or cotton linters as raw materials, processed into spinning stock solution, and then wet-spun , The wastewater passes through the biochemical system (various forms of anaerobic and aerobic processes) and the effluent COD≤400mg / L.

[0022] (1) The waste water flows into the buffer pool by itself, and 1500ppm ferrous sulfate is added. After being mixed evenly by the impeller of the lifting pump, it enters the catalytic oxidation reactor, and at the same time, 180ppm hydrogen peroxide is added, reacted for 8 minutes, flows into the oxidation flocculation tank for 40 minutes, and adjusts the pH value To 7.0, add flocculant to precipitate for 5 hours, the COD of the effluent is 100mg / L, and the COD removal rate is 75%.

[0023] (2) Put the iron-containing sludge in the sludge thickening tank into the sludge dissolving tank, add a certain amount of ...

Embodiment 3

[0026] Example 3: In a printing and dyeing factory mainly processing cotton, hemp, chemical fiber and their blended products, the wastewater passes through biochemical systems (various forms of anaerobic and aerobic processes) and the effluent COD≤180mg / L.

[0027] (1) The waste water flows into the buffer pool by itself, and 1200ppm ferrous sulfate is added. After being mixed evenly by the impeller of the lifting pump, it enters the catalytic oxidation reactor, and 130ppm hydrogen peroxide is added at the same time, and reacts for 7 minutes. To 7.0, add flocculant to precipitate for 5 hours, the effluent COD is 60mg / L, and the COD removal rate is 67%.

[0028] (2) Put the iron-containing sludge in the sludge thickening tank into the sludge dissolving tank, add a certain amount of waste hydrochloric acid, and turn on the mixer to fully dissolve the sludge to form a ferric iron solution. At this time, the pH value is 1.3 ;

[0029] (3) Put the ferric iron solution into the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com