Comprehensive recycling method of platinum-rhenium containing reformed spent catalyst

A waste catalyst and recovery method technology, applied in chemical recovery, aluminum sulfur compounds, process efficiency improvement, etc., can solve the problems of low recovery rate of platinum and rhenium, low dissolution efficiency, difficult separation of platinum and rhenium, etc., and achieve rhenium High recovery rate, short leaching time, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

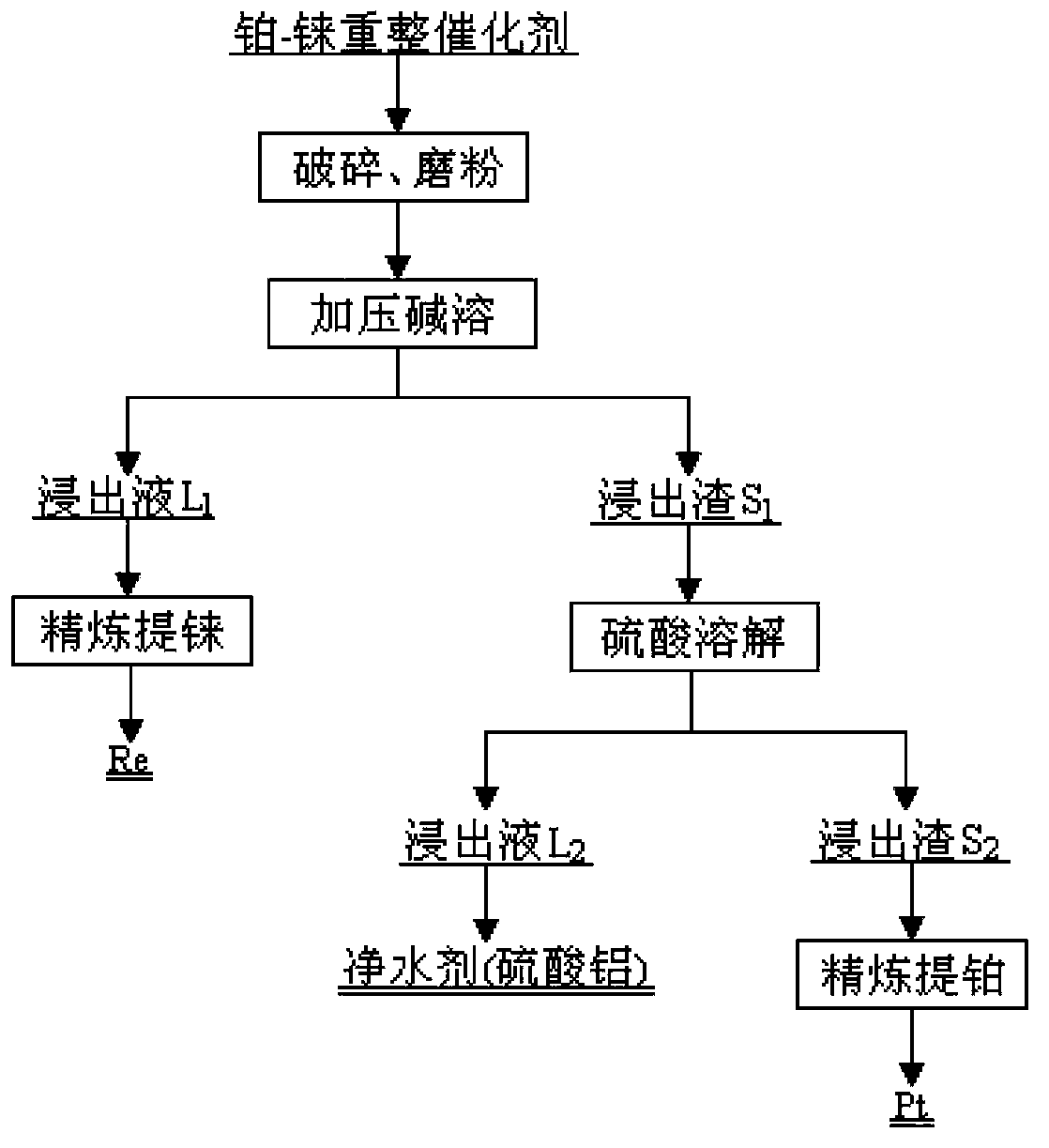

Method used

Image

Examples

Embodiment 1

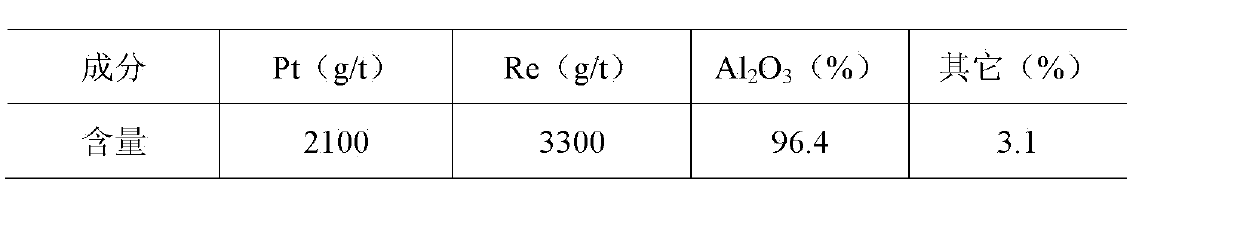

[0025] Take the platinum-rhenium reforming waste catalyst to crush and grind to a powder with a particle size of 30 mesh, then weigh 1000 g of the ground material, and add 50 g of Na 2 CO 3 , Add 3000 ml of water to adjust the slurry, stir in a 5 L reactor and heat to 150℃, control the pressure at 4.8 MPa, keep the temperature for 2 h, cool and filter to obtain the leachate L 1 And leaching residue S 1 ,To the leaching solution L 1 Add 8 g of KCl to precipitate rhenium, and then wash the potassium salt with water after hydrogen reduction at 800°C to obtain 3.06 g rhenium powder with a purity of 99.95%. The recovery rate is 92.73%.

[0026] The leaching residue S 1 Dissolve with 20% sulfuric acid, the liquid-solid ratio is 3:1, the reaction temperature is 100°C, the reaction time is 2 hours, and then cool and filter to obtain the leachate L 2 And leaching residue S 2 ,The leaching solution L 2 Concentrate and crystallize to obtain industrial-grade aluminum sulfate water purifier, and...

Embodiment 2

[0028] Take the platinum-rhenium reforming waste catalyst to crush and grind to a powder with a particle size of 80 mesh, then weigh 1000 g of the ground material, and add 100 g of NaHCO 3 , Add 4000 ml of water to adjust the slurry, stir in a 5 L reactor and heat to 120°C, control the pressure at 2.1MPa, keep the temperature constant for 4 h, cool and filter to obtain the leachate L 1 And leaching residue S 1 ,To the leaching solution L 1 Add 8 g of KCl to precipitate rhenium, and then wash the potassium salt with water after hydrogen reduction at 800°C to obtain 3.11 g rhenium powder with a purity of 99.95%, with a recovery rate of 94.24%.

[0029] The leaching residue S 1 Dissolve with 30% sulfuric acid, the ratio of liquid to solid is 5:1, the reaction temperature is 100°C, the reaction time is 2 hours, cool and filter to obtain the leachate L 2 And leaching residue S 2 ,The leaching solution L 2 Concentrate and crystallize to obtain industrial-grade aluminum sulfate water purif...

Embodiment 3

[0031] Take the platinum-rhenium reforming waste catalyst to crush and grind to a powder with a particle size of 100 mesh, then weigh 1000 g of the ground material, and add 150 g of NaHCO 3 , Add 4000 ml of water to adjust the slurry, stir in a 5L reactor and heat to 180℃, control the pressure at 1.3MPa, keep the temperature for 3 hours, cool and filter to obtain the leachate L 1 And leaching residue S 1 ,To the leaching solution L 1 Add 8 g of KCl to precipitate rhenium, and then wash the potassium salt with water after hydrogen reduction at 800°C to obtain 3.13 g rhenium powder with a purity of 99.95%. The recovery rate is 94.85%.

[0032] The leaching residue S 1 Dissolve with 40% sulfuric acid, the liquid-solid ratio is 7:1, the reaction temperature is 100°C, the reaction time is 3 hours, and then cool and filter to obtain the leachate L 2 And leaching residue S 2 ,The leaching solution L 2 Concentrate and crystallize to obtain industrial-grade aluminum sulfate water purifier, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com