Method and device for processing ethylene oxide waste gas

A technology of ethylene oxide and treatment equipment, which is applied in the field of ethylene oxide sterilization waste gas treatment, can solve the problems of irresponsible space discharge, no reliable tail gas treatment system, etc., and achieve good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

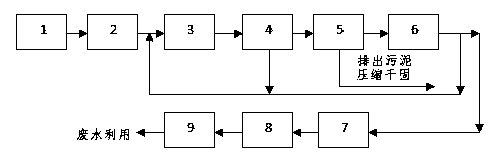

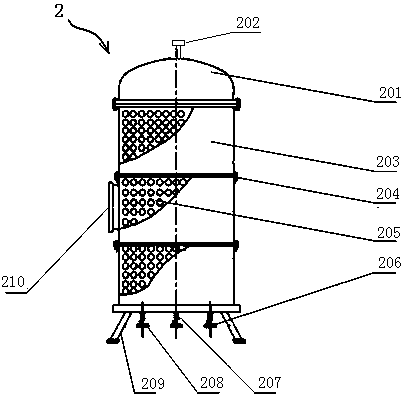

[0032] See figure 1 , the treatment device of the ethylene oxide waste gas provided by the present invention is composed of a combined device 1, a turbulent ball combined tower 2, an aeration tank 3, a biological purification tank 4, a biogas tank 5, a settling tank 6, and a biological filter tank 7 connected in sequence , an ecological gravel bed 8 and a biomonitoring pool 9.

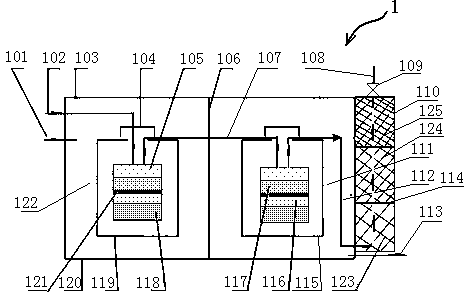

[0033] Combiner such as figure 2 As shown, it includes a closed box body 120 and a composite air filter box 110 with a movable cover 103. The box body 120 is provided with an air inlet pipe 102, an exhaust pipe 112, a water inlet pipe 101, and a drain pipe 113. The dividing plate 106 of the water hole is divided into two unit spaces, and a stainless steel pressure reactor 122, 111 is respectively arranged in each unit space, and the reactor 122, 111 comprises respectively the shell 119, 115 that concentrated sulfuric acid is housed, and the shell 119 Each reactor 122, 111 is provided with loam cake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com