A magnetic pulse abrasive water jet cutting machine

A technology of abrasive water jet and cutting machine, which is applied in the direction of abrasive jet machine tools, abrasives, abrasive feeding devices, etc., can solve the problems of inability to generate pulsating jets, unfavorable abrasive grain speed, low firing frequency, etc., and achieve good energy exchange and Acceleration effect, good cutting or impact crushing effect, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

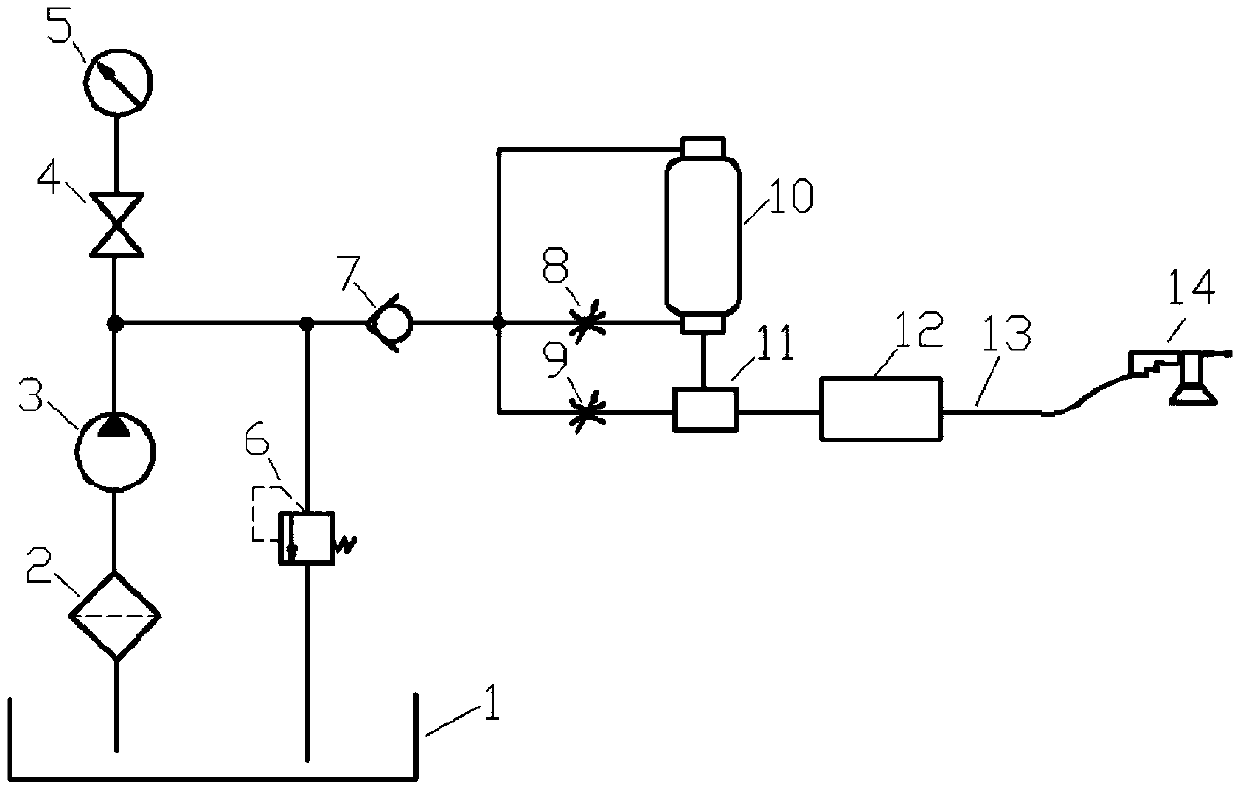

[0013] exist figure 1 Among them, the magnetic pulse abrasive water jet cutting machine includes a water tank 1, a filter 2, a plunger pump 3, a stop valve 4, a pressure gauge 5, a safety valve 6, a one-way valve 7, an abrasive volume regulating valve 8, and a water volume regulating valve 9 , abrasive tank 10, abrasive mixing device 11, magnetic pulse device 12, spray gun 14 and pressure-resistant rubber hose 13 connecting them. The inlet of the filter 2 is connected to the water tank 1, the outlet of the filter 2 is connected to the inlet of the plunger pump 3, the outlet of the plunger pump 3 is connected with a shut-off valve 4 and a pressure gauge 5, and the bypass of the plunger pump 3 is connected with a safety valve 6 , the safety valve 6 plays the role of overload protection. There is a one-way valve 7 connected between the plunger pump 3 and the safety valve 6. The one-way valve 7 prevents the abrasive water from flowing back when the machine stops. After the one-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com