Preparation method of microporous nanocarbon balls with high specific surface area and uniform and regular aperture

A technology with high specific surface area and nano-carbon spheres, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as difficult promotion and application, cumbersome preparation procedures, etc., and achieve easy product separation, The effect of avoiding environmental pollution and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Mix urea and choline chloride together in a molar ratio of 2:1, stir vigorously with a glass rod, and then stir on a magnetic stirrer for 12 hours to obtain an ionic liquid;

[0030] (2) The molar ratio of the reaction mixture copper nitrate trihydrate: N-methylimidazole: ionic liquid is 5:0.5:2.5. The specific operation is as follows: take 0.073g of ionic liquid, add 0.014g of N-methylimidazole, put it in a heating mantle at 60°C while stirring and heat, after the N-methylimidazole is dissolved, then add 0.4097g of copper nitrate trihydrate, Continue to stir for 30 minutes, then put it in an oven at 60°C, take it out after 5 hours, let it cool down to room temperature naturally, filter it with suction, rinse it with distilled water for 3 times, and then put it in an oven at 80°C for drying.

[0031] (3) Finally, soak the dried sample in methanol and stir it constantly, changing the methanol every 12 hours, repeat this process twice, and let it dry naturally.

[00...

Embodiment 2

[0036]The preparation process is similar to Example 1, except that the selected metal salts, organic ligands and carbonization procedures are different. The specific differences are as follows:

[0037] The metal salt used in this example is nickel acetate tetrahydrate, the organic ligand is terephthalic acid, and the molar ratio of the reaction mixture nickel acetate, terephthalic acid, and ionic liquid is 5:1:2.5.

[0038] The specific carbonization procedure is: heating from room temperature to 300 °C at a rate of 0.5 °C / min, then heating from 300 °C to 600 °C at a rate of 0.5 °C / min, and keeping it for 5 hours, and finally cooling down to room temperature naturally.

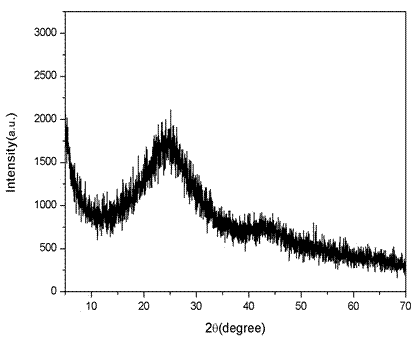

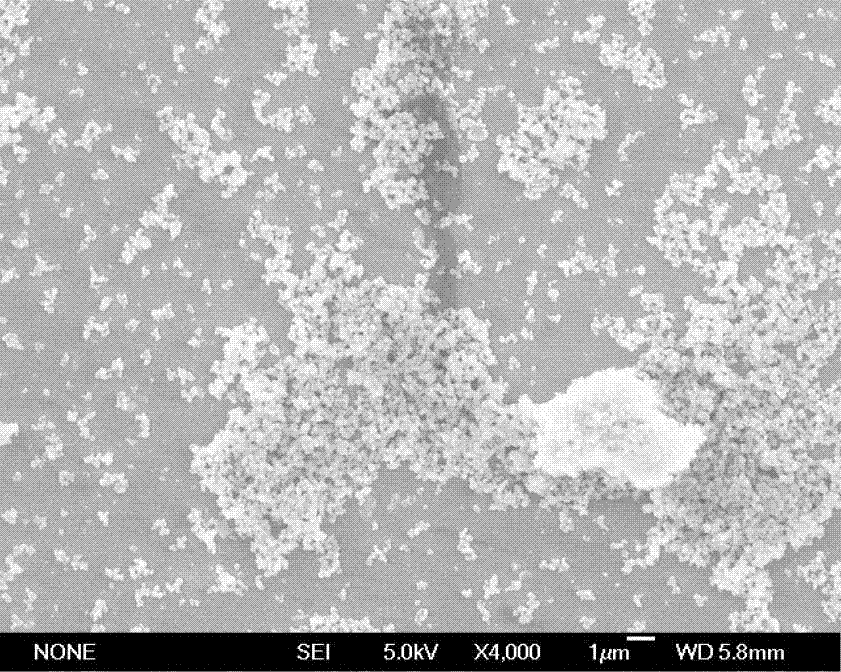

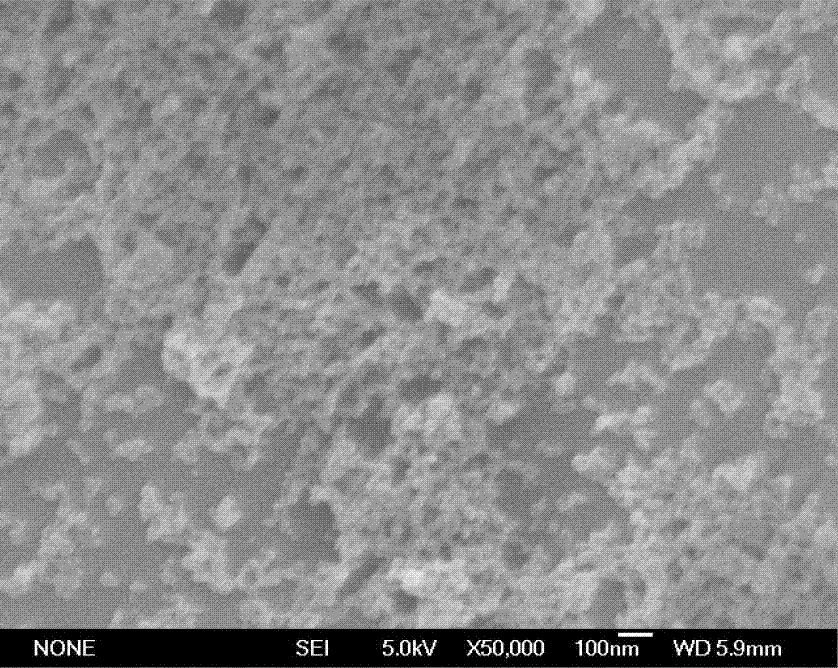

[0039] The size of the porous nano carbon spheres obtained in this example is 70nm, the size is uniform, the pore diameter is 0.8nm, and the specific surface area is 1300m 2 / g.

Embodiment 3

[0041] The preparation process is similar to Example 1, except that the selected metal salts, organic ligands and carbonization procedures are different. The specific differences are as follows:

[0042] The metal salt used in this example is aluminum nitrate nonahydrate, the organic ligand is 2-methylimidazole, and the molar ratio of the reaction mixture aluminum nitrate nonahydrate, 2-methylimidazole, and ionic liquid is 5:0.5:2.

[0043] The specific carbonization procedure is as follows: heating from room temperature to 700 °C at a rate of 1 °C / min, keeping it for 8 hours, and then cooling down to room temperature naturally.

[0044] The size of the porous nano carbon spheres obtained in this example is 200nm, the size is uniform, the pore diameter is 1.3nm, and the specific surface area is 1700m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com