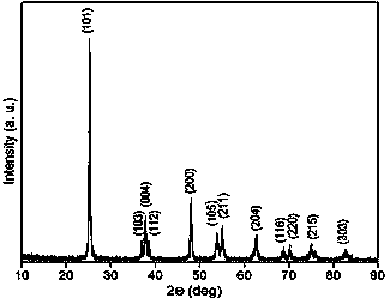

Method used for preparing anatase type core-shell nanometer titanium dioxide and application of anatase type core-shell nanometer titanium dioxide in dye degradation

A nano-titanium dioxide and anatase-type technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as corrosion of glass and human bones, and limit development, and achieve high-efficiency photocatalytic activity and strong High cycle performance and high degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] TiOSO 4 , deionized water, ethanol, and sucrose as initial raw materials, weighed 0.7g TiOSO 4, 4.0g sucrose, measure 30 ml ethanol, 10 ml distilled water, stir and mix evenly, put the mixture in a 100 ml stainless steel polytetrafluoroethylene reactor, put the reactor in an oven at 160°C, heat for 6 h, cool to room temperature. Washed, dried in vacuum at 60°C, calcined at 450°C for 4 h, and cooled to room temperature naturally. Recorded as 1# catalyst.

Embodiment 2

[0039] TiOSO 4 , deionized water, ethanol, and sucrose as initial raw materials, weighed 0.7g TiOSO 4 , 4.0g sucrose, measure 40 ml ethanol, 0ml distilled water, stir and mix evenly, put the mixed solution in a 100 ml stainless steel polytetrafluoroethylene reactor, place the reactor in an oven at 160°C, heat for 6 h, and cool to room temperature. Washed, dried in vacuum at 60°C, calcined at 450°C for 4 h, and cooled to room temperature naturally.

Embodiment 3

[0041] TiOSO 4 , deionized water, ethanol, and sucrose as initial raw materials, weighed 0.7g TiOSO 4 , 4.0g sucrose, measure 35 ml ethanol, 5 ml distilled water, stir and mix evenly, put the mixture in a 100 ml stainless steel polytetrafluoroethylene reactor, put the reactor in an oven at 160°C, heat for 6 h, cool to room temperature. Washed, dried in vacuum at 60°C, calcined at 450°C for 4 h, and cooled to room temperature naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com