Synchronous grouting grout for shield construction control and grouting method thereof

A technology of simultaneous grouting and grouting, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of long setting time, large volume shrinkage, unstable segment structure, etc., and achieve the effect of meeting safety requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

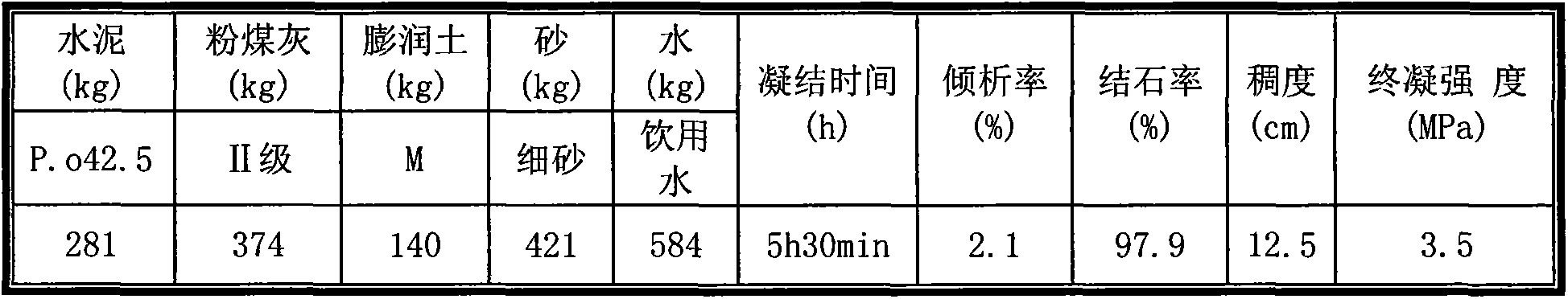

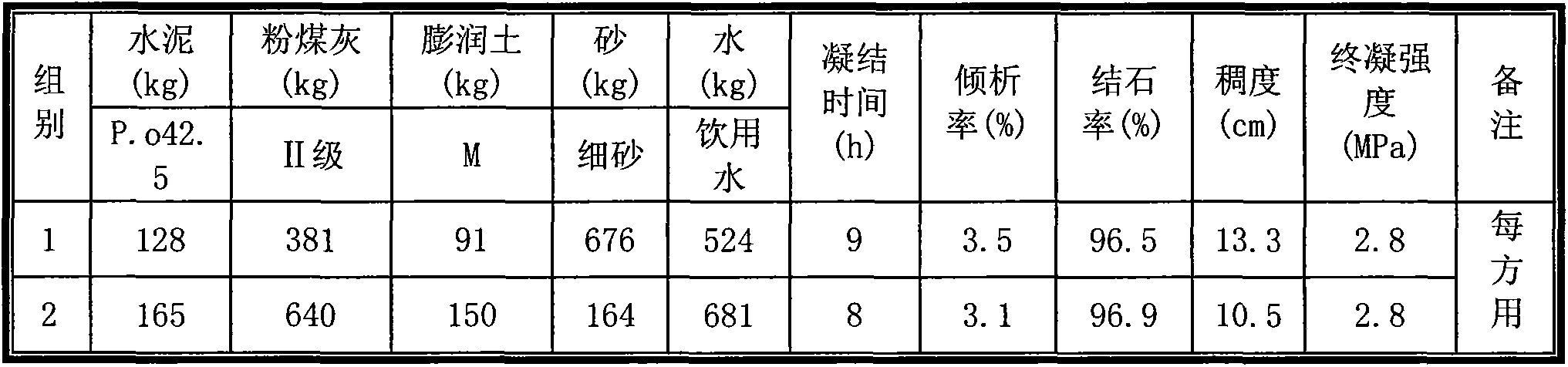

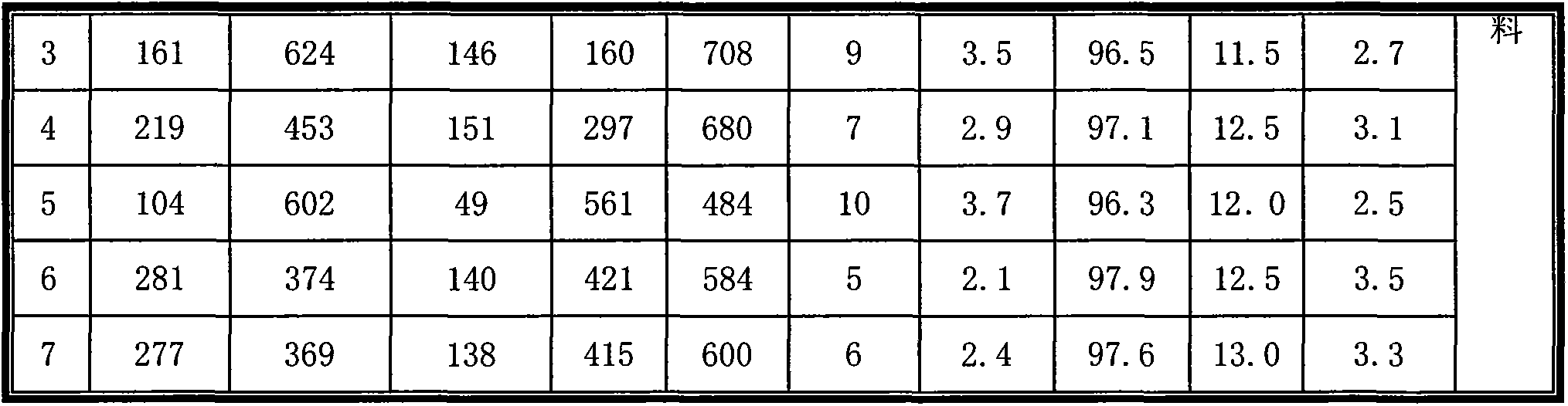

[0012] The mortar mixing station is used to mix the slurry. When actually mixing the slurry, first set the weighing weight in the computer of the mixing station according to the mixing ratio of the slurry, and send the weighed raw materials into the mixing tank, and use the mechanical forced mixing method to mix. The quality of grouting liquid and mortar mixing meets the requirements of the Ministry of Construction JGJ70-2009 "Test Methods for Basic Properties of Building Mortar".

[0013] In Figure 1, it is the mortar configured according to the ratio of the slurry. The mortar is in a flow-plastic state and can be transported to the shield machine for use. The grouting system of the shield machine is injected into the space behind the shield shell and outside the segments for filling. See Figure 2 for the mortar effect after filling and setting.

[0014] Construction example:

[0015] The geological conditions in the section 10 of the second phase of Beijing Metro Line 8 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com