A kind of organosilicon-modified waterborne acrylate resin and preparation method thereof

A technology of water-based acrylate and silicone, which is applied in the field of silicone-modified water-based acrylate resin and its preparation, can solve the problems of expensive raw materials, complicated process, and difficult gelation, etc. Simple, excellent effect of solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

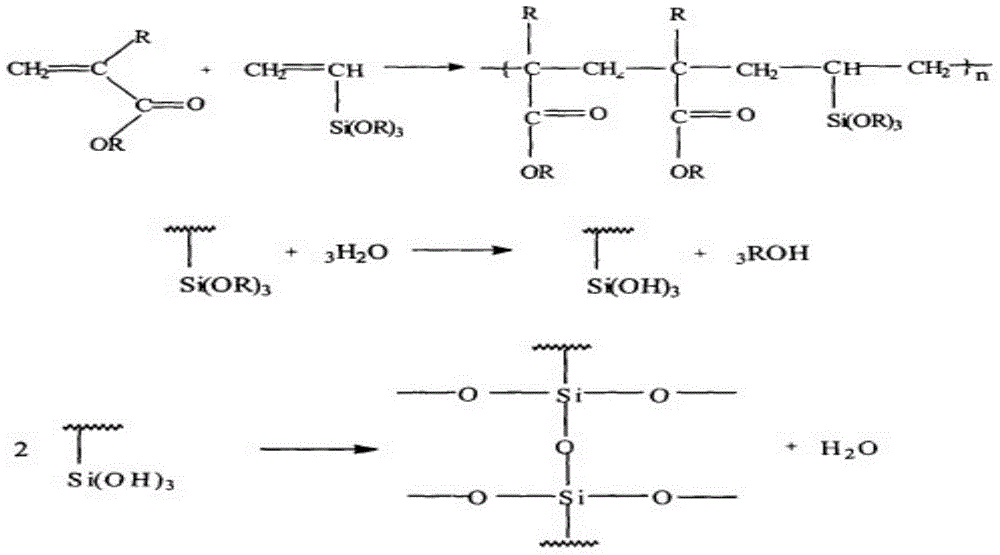

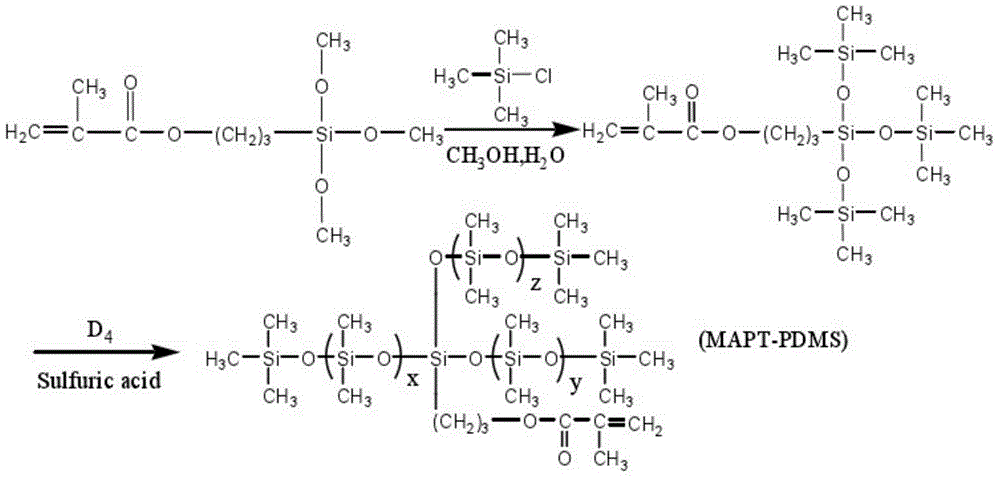

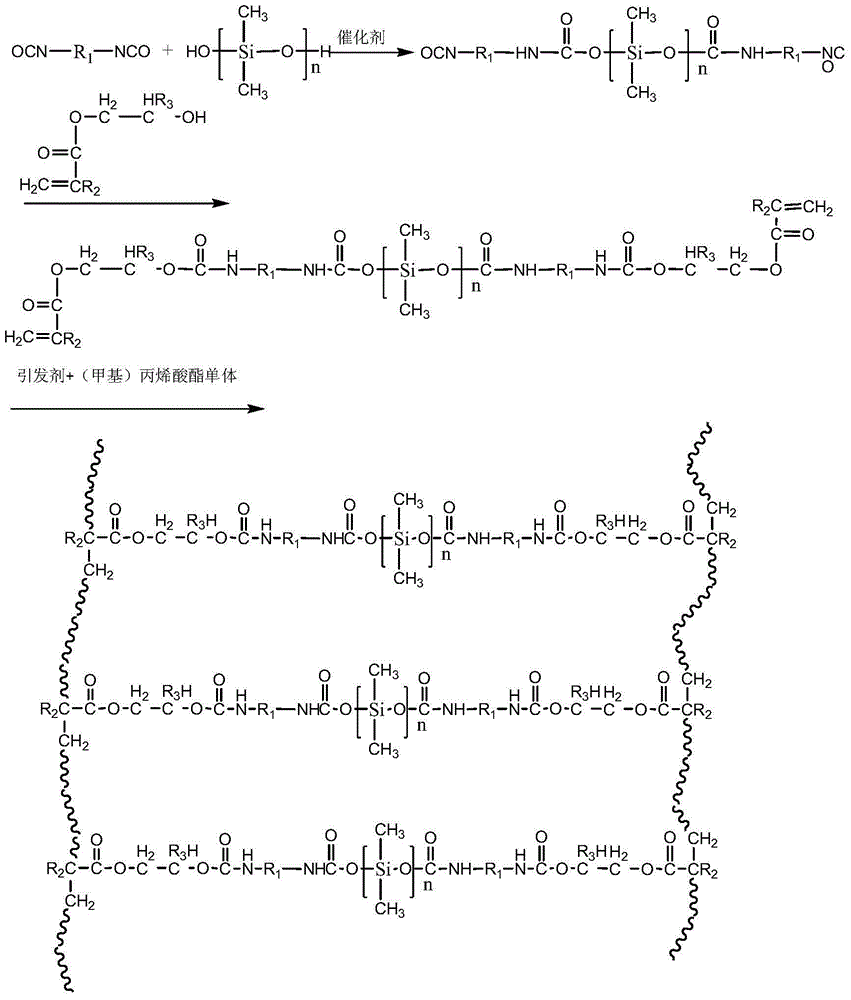

Method used

Image

Examples

Embodiment 1

[0050] Embodiment one control NCO:OH is 2:1

[0051] (1) Add 40.29g (120°C vacuum dehydration for 2h) of hydroxyl silicone oil (average molecular weight is about 300), 0.1g of di-n-butyltin dilaurate and 59.71g of isophorone diisocyanate into a four-necked flask. The reaction was stirred at ℃ for 1-3 hours, and the NCO was tested every half hour until the NCO content was 5.6 wt%, and the reaction was stopped.

[0052] (2) Lower the reaction temperature of step (1) to 60°C, add 17.48g of hydroxyethyl methacrylate and 0.14g of hydroquinone, react for 1-1.5h, take samples for infrared testing every half hour, until 2270cm -1 Absorption peaks appear everywhere, and the reaction stops.

[0053] (3) The reaction temperature of step (2) is lowered to room temperature, and 145g methyl methacrylate, 6g methacrylic acid, 149g n-butyl acrylate, 600g deionized water, 8g sodium dodecylbenzenesulfonate and 4g Triton 100, stirred at a high speed until it was in the form of an emulsion to o...

Embodiment 2

[0059] Embodiment two control NCO:OH is 2:1

[0060] (1) Add 40.29g (120°C vacuum dehydration for 2h) of hydroxyl silicone oil (average molecular weight is about 300), 0.1g of di-n-butyltin dilaurate and 59.71g of isophorone diisocyanate into a four-necked flask. The reaction was stirred at ℃ for 1-3 hours, and the NCO was tested every half hour until the NCO content was 5.6 wt%, and the reaction was stopped.

[0061] (2) Lower the reaction temperature of step (1) to 60°C, add 17.48g of hydroxyethyl methacrylate and 0.14g of hydroquinone, react for 1-1.5h, take samples for infrared testing every half hour, until 2270cm -1 Absorption peaks appear everywhere, and the reaction stops.

[0062] (3) The reaction temperature of step (2) is down to room temperature, add 200g methyl methacrylate, 6g methacrylic acid, 94g n-butyl acrylate, 600g deionized water, 8g sodium dodecylbenzenesulfonate and 4g Triton 100, stirred at a high speed until it was in the form of an emulsion to obtai...

Embodiment 3

[0068] Embodiment 3 Control NCO:OH=1.2:1

[0069] (1) Add 52.93g (120°C vacuum dehydration for 2h) of hydroxyl silicone oil (average molecular weight is about 300), 0.1g of di-n-butyltin dilaurate and 47.07g of isophorone diisocyanate into a four-necked flask. The reaction was stirred at ℃ for 1-3 hours, and the NCO was tested every half hour until the NCO content was 5.6 wt%, and the reaction was stopped.

[0070] (2) Lower the reaction temperature of step (1) to 60°C, add 5.51g of hydroxyethyl methacrylate and 0.07g of hydroquinone, react for 1 to 1.5 hours, take samples for infrared testing every half hour, until 2270cm -1 Absorption peaks appear everywhere, and the reaction stops.

[0071] (3) The reaction temperature of step (2) is lowered to room temperature, and 216g methyl methacrylate, 6g methacrylic acid, 78g n-butyl acrylate, 600g deionized water, 8g sodium dodecylbenzenesulfonate and 4g Triton 100, stirred at a high speed until it was in the form of an emulsion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com