ZnO-synergized montmorillonite flame-retardant polystyrene nanocomposite and preparation method thereof

A polystyrene nano-composite material technology, applied in the field of polymer flame retardant, can solve the problems of polymer matrix mechanical properties, processing performance damage, poor compatibility between MMT and polymer, and insignificant flame retardant effect, and achieves resistance to Remarkable effect of combustion and smoke suppression, easy to expand large-scale production, excellent flame retardant and smoke suppression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of a ZnO synergistic montmorillonite flame retardant polystyrene nanocomposite:

[0032] (1) Components and parts by mass are as follows:

[0033] General-purpose polystyrene resin (PG-383, purchased from Taiwan Chi Mei Industrial Co., Ltd.): 75 copies;

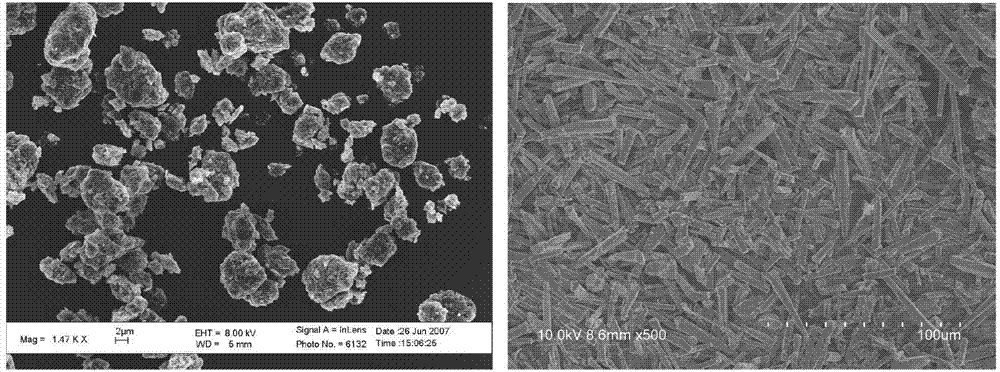

[0034] Cetyltrimethylammonium chloride modified sodium-based montmorillonite (see Zhang JC, Zhang ZP, Hu B, Liu G. New methods of prepatation and property study of the montmorillonite modified with CTAB. Materials and Design , 2011, 284-286,: 377-381): 5 copies;

[0035] ZnO microrod (purchased from Shanghai Yuejiang Titanium Dioxide Chemical Products Co., Ltd.): 0.5 part;

[0036] MPP (purchased from Nantong Sier Chemical Co., Ltd.): 15 copies;

[0037] SBS (purchased from Nanjing Jintian Plastic Co., Ltd.): 2 copies;

[0038] Other common PS additives: 2.5 parts;

[0039] (2) Preparation method: The above materials are put into a high-speed mixer for stirring, the stirring speed is set to 200 rpm, an...

Embodiment 2

[0042]A preparation method of ZnO synergistic montmorillonite flame retardant polystyrene nanocomposite material, which is different from Example 1 in the formula in step (1): general polystyrene resin: 67.5 parts, 18 parts Alkyltrimethylammonium chloride modified sodium-based montmorillonite: 1 part, ZnO microrod: 1 part, MCA: 20 parts, SEBS: 10 parts, other common PS additives: 0.5 part.

[0043] The temperature setting of the twin-screw extruder in step (3) is as follows:

[0044] Zone 1 (°C)

Embodiment 3

[0045] Example 3. A preparation method of ZnO synergistic montmorillonite flame retardant polystyrene nanocomposite material, which is different from Example 1 in the formula in step (1): general polystyrene resin: 80, dodecane Sodium-based montmorillonite modified with trimethylammonium chloride: 2, ZnO microrod: 0.1, MPP: 15, SEPS: 2 parts, other common PS additives: 0.9

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com