Low-melting-point metal thermal-conducting paste as well as preparation method and application thereof

A low-melting-point metal, thermally conductive paste technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems such as oxidation failure of low-melting-point metal thermal conductive paste, and achieve the effect of preventing oxidation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

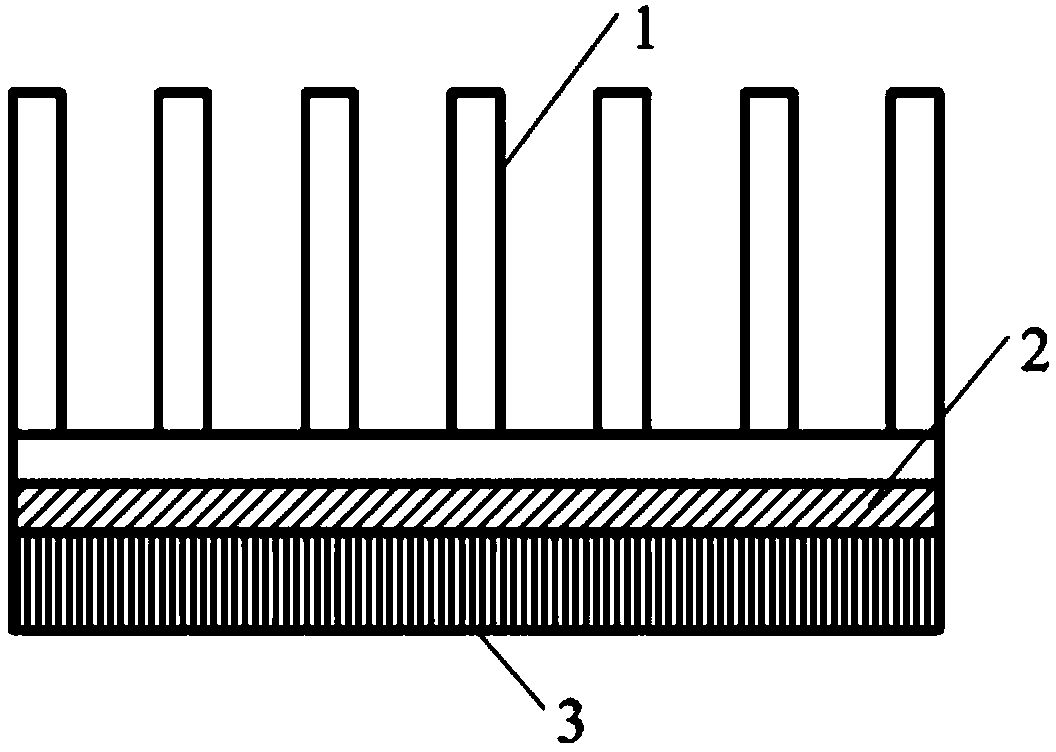

Image

Examples

Embodiment 1

[0024] Embodiment 1 A kind of low-melting point metal heat conduction paste, consists of the following components by weight:

[0025] The mass fraction of gallium indium tin alloy (the mass fraction of each component is Ga: 66%, In: 20.5%, Sn: 13.5%) is 94.9%, the mass fraction of sodium sulfide is 0.1%, and the mass fraction of sodium gallate is 5%. .

[0026] Among them, gallium indium tin alloy can maintain a liquid state at a temperature of 10°C and above.

[0027] The method for preparing the low-melting-point metal thermal paste described in this embodiment comprises the following steps:

[0028] (1) Gallium indium tin alloy is melted by hot melting method, and its mass fraction in thermal paste is 94.9%;

[0029] (2) Add sodium sulfide with a mass fraction of 0.1% and sodium gallate powder with a mass fraction of 5% to the molten low melting point metal;

[0030] (3) Stir the mixture in step (2) in an air-isolated environment with a rotation speed of 480 rpm and a st...

Embodiment 2

[0031] Embodiment 2 A kind of low-melting-point metal heat conduction paste, consists of the following components by weight:

[0032] The mass fraction of gallium indium tin zinc alloy (the mass fraction of each component is Ga: 61%, In: 24%, Sn: 13%, Zn: 2%) is 94.9%, and the mass fraction of ferrous chloride is 5% , the mass fraction of sodium gallate is 0.1%.

[0033] Among them, the gallium indium tin zinc alloy can maintain a liquid state at a temperature of 10°C and above.

[0034] The method for preparing the low-melting-point metal thermal paste described in this embodiment comprises the following steps:

[0035] (1) Gallium indium tin zinc alloy is melted by hot melting method, and its mass fraction in thermal paste is 94.9%;

[0036] (2) Add ferrous chloride with a mass fraction of 5% and sodium gallate powder with a mass fraction of 0.1% to the molten low melting point metal;

[0037] (3) Stir the mixture in step (2) in an air-isolated environment with a rotation...

Embodiment 3

[0038] Embodiment 3 A kind of low-melting point metal heat conduction paste, consists of the following components by weight:

[0039] The mass fraction of gallium-lead alloy (the mass fraction of each component is Ga: 98%, Pb: 2%) is 99.8%, the mass fraction of magnesium sulfide is 0.1%, and the mass fraction of sodium gallate is 0.1%.

[0040] Among them, the gallium-lead alloy can maintain a liquid state at a temperature of 30°C or higher.

[0041] The method for preparing the low-melting-point metal thermal paste described in this embodiment comprises the following steps:

[0042] (1) Gallium-lead alloy is melted by hot melting method, and its mass fraction in thermal paste is 99.8%;

[0043] (2) Add magnesium sulfide with a mass fraction of 0.1% and sodium gallate powder with a mass fraction of 0.1% to the molten low melting point metal;

[0044] (3) Stir the mixture in step (2) in an air-isolated environment with a rotation speed of 300 rpm and a stirring time of 120 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com