Nitrogen oxide fluorescent powder for near ultraviolet excitation and preparation method thereof

A nitrogen oxide and near-ultraviolet technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of harsh synthesis conditions and late start, and achieve the effect of simple and feasible manufacturing method, easy operation and high matching degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

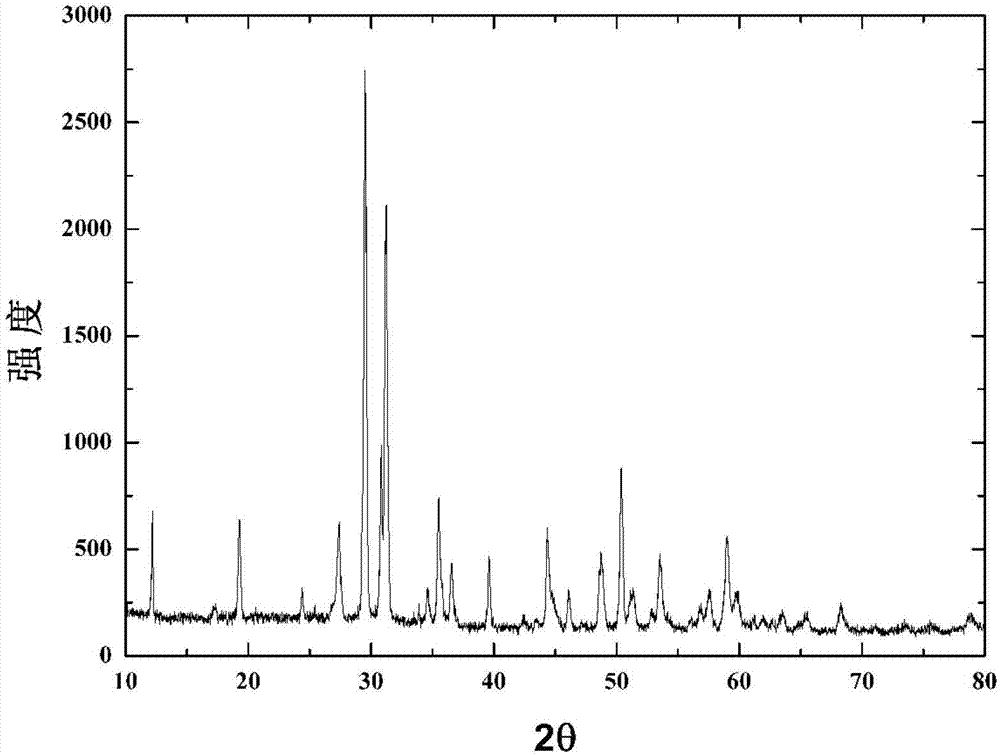

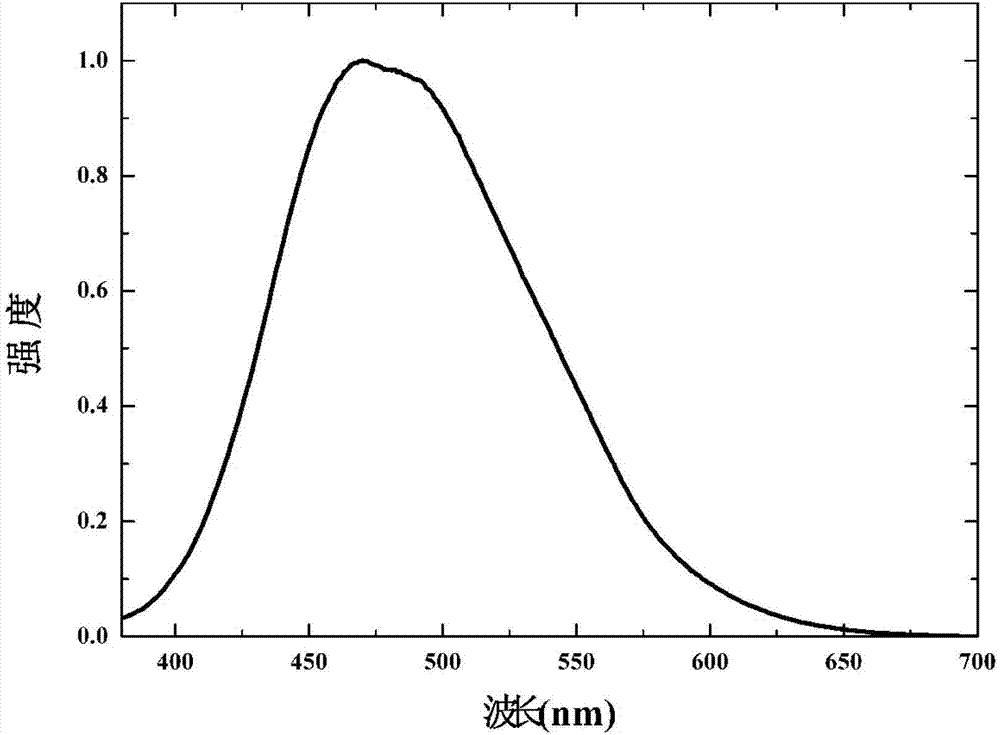

[0041] weigh Y 2 o 3 55.89 grams, Al 2 o 3 5.10 g, α-Si 3 N 4 7.01 g, CeO 2 0.86 g, AlF 3 1.36 grams, fully ground and mixed, put into an alumina crucible, cover the crucible lid, put into a high temperature furnace, under the condition of 1550 ℃, 10%-H 2 / N 2 Roasting under the atmosphere for 10 hours, take it out when cooled to room temperature, grind and disperse, then soak and wash with a hydrochloric acid solution with a mass concentration of 2%, then wash with deionized water until the pH value is neutral, and dry; Nitride phosphor excited in the near ultraviolet, its composition is Y 9.90 Ce 0.10 Al 2 Si 3 o 12 N 4 . For the XRD spectrum of the phosphor see figure 1 , and the emission and excitation spectra, respectively, see image 3 with Figure 4 .

Embodiment 2

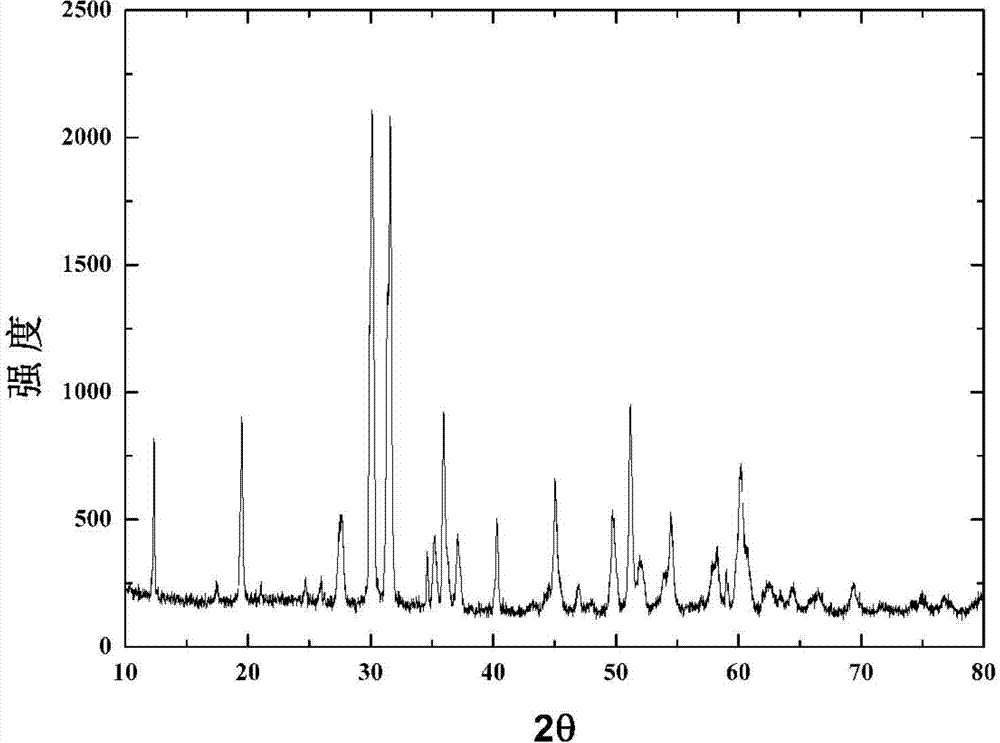

[0043] weigh Y 2 o 3 55.61 grams, Al 2 o 3 5.10 g, β-Si 3 N 4 7.01 g, CeO 2 1.29 grams, from 0.1 grams, fully ground and mixed, put into an alumina crucible, cover the crucible lid, put into a high-temperature furnace, under the condition of 1500 ℃, 5%-H 2 / N 2 Roasting under the atmosphere for 12 hours, take it out when cooled to room temperature, grind and disperse, then soak and wash with a sulfuric acid solution with a mass concentration of 10%, then wash with deionized water until the pH value is neutral, and dry; Nitride phosphor excited in the near ultraviolet, its composition is Y 9.85 Ce 0.15 Al 2 Si 3 o 12 N 4 .

Embodiment 3

[0045] weigh Y 2 o 3 55.89 grams, La 2 o 3 0.41 g, Al 2 o 3 5.10 g, α-Si 3 N 4 7.01 g, CeO 2 0.86 g, NH 4 F0.7 grams, fully ground and mixed, put into an alumina crucible, cover the crucible lid, put into a high temperature furnace, under the condition of 1600 ℃, 20%-H 2 / N 2 Roasting under the atmosphere for 8 hours, take it out when cooled to room temperature, grind and disperse, then soak and wash with a sulfuric acid solution with a mass concentration of 3%, then wash with deionized water until the pH value is neutral, and dry; Nitride phosphor excited in the near ultraviolet, its composition is Y 9.85 La 0.05 Ce 0.10 al 2 Si 3 o 12 N 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com