Plasma thruster based on multilevel tip cusped magnetic field

A technology that can cut magnetic fields and plasma, applied in the field of ion propulsion, can solve the problems of low power density and short life of thrusters, and achieve the effect of avoiding space charge saturation effect, improving life and improving life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

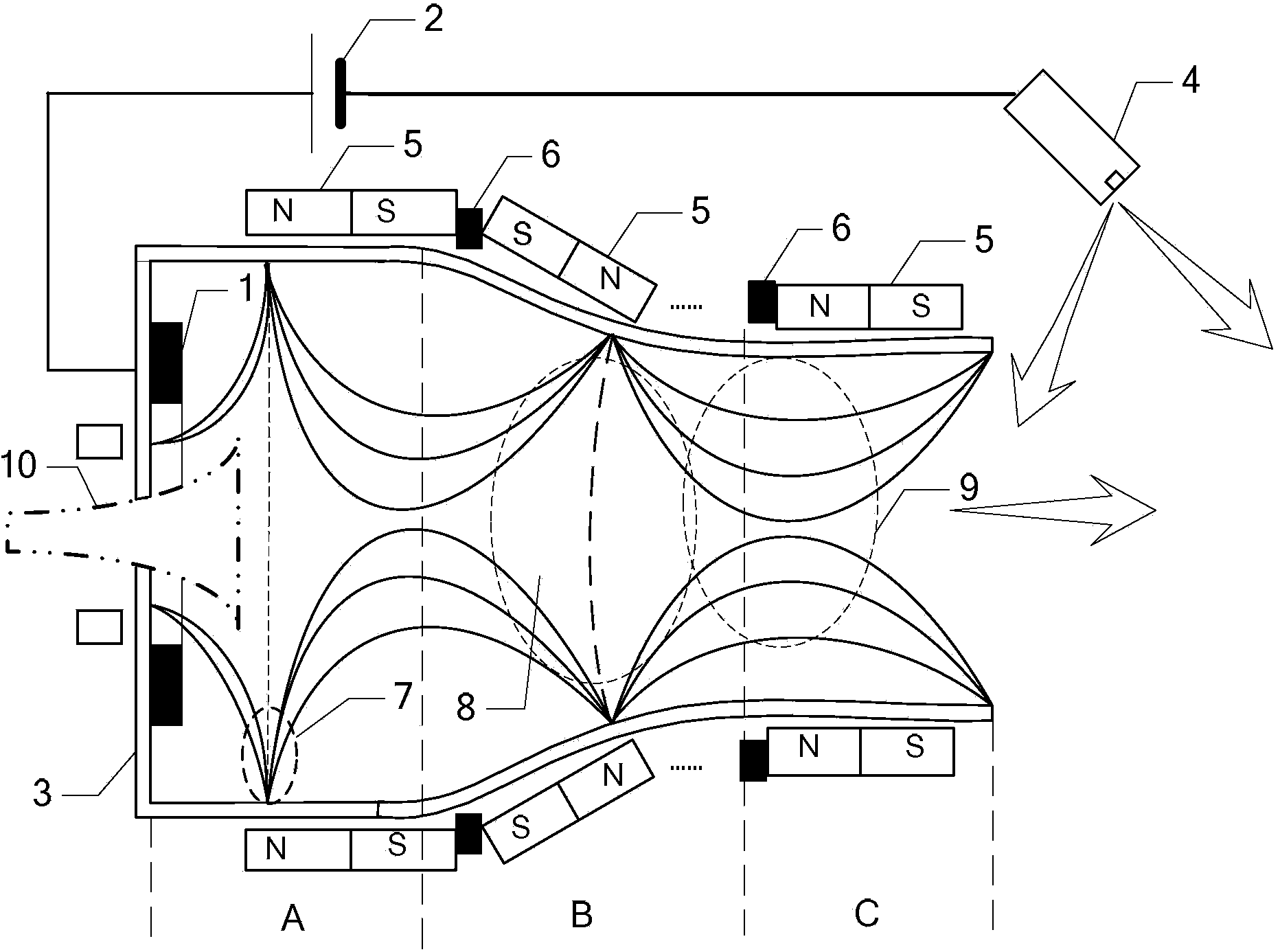

[0022] Specific implementation mode one: see figure 1 Describe this embodiment, a plasma thruster based on a multi-stage cusp magnetic field described in this embodiment, which includes an anode 1, a power supply 2, a circular ceramic cavity 3, a hollow cathode 4, and multiple circular rings permanent magnet 5, a plurality of magnetically permeable rings 6; the number of the circular permanent magnets 5 is greater than or equal to 3,

[0023] The bottom of the circular ceramic cavity 3 is provided with a working fluid jet hole, and an anode 1 is arranged around the working fluid jet hole,

[0024] The circular ceramic cavity 3 is divided into a front section A, a middle section B and a back section C along the emission direction of the working medium jet, the front section A is a barrel-shaped structure, and the middle section B is a circle with an isosceles trapezoidal axial section. Cylindrical structure, the rear section C is a cylindrical structure, and the inner diameter...

specific Embodiment approach 2

[0027] Specific implementation mode two: see figure 1 To describe this embodiment, the difference between this embodiment and the plasma thruster based on the multi-stage cusp magnetic field described in the first embodiment is that the number of the circular permanent magnets 5 is less than 15.

specific Embodiment approach 3

[0028] Specific implementation mode three: see Figure 4 Describe this embodiment, the difference between this embodiment and the plasma thruster based on the multi-stage cusped magnetic field described in the first or second embodiment is that the number of the circular permanent magnets 5 is equal to 3 .

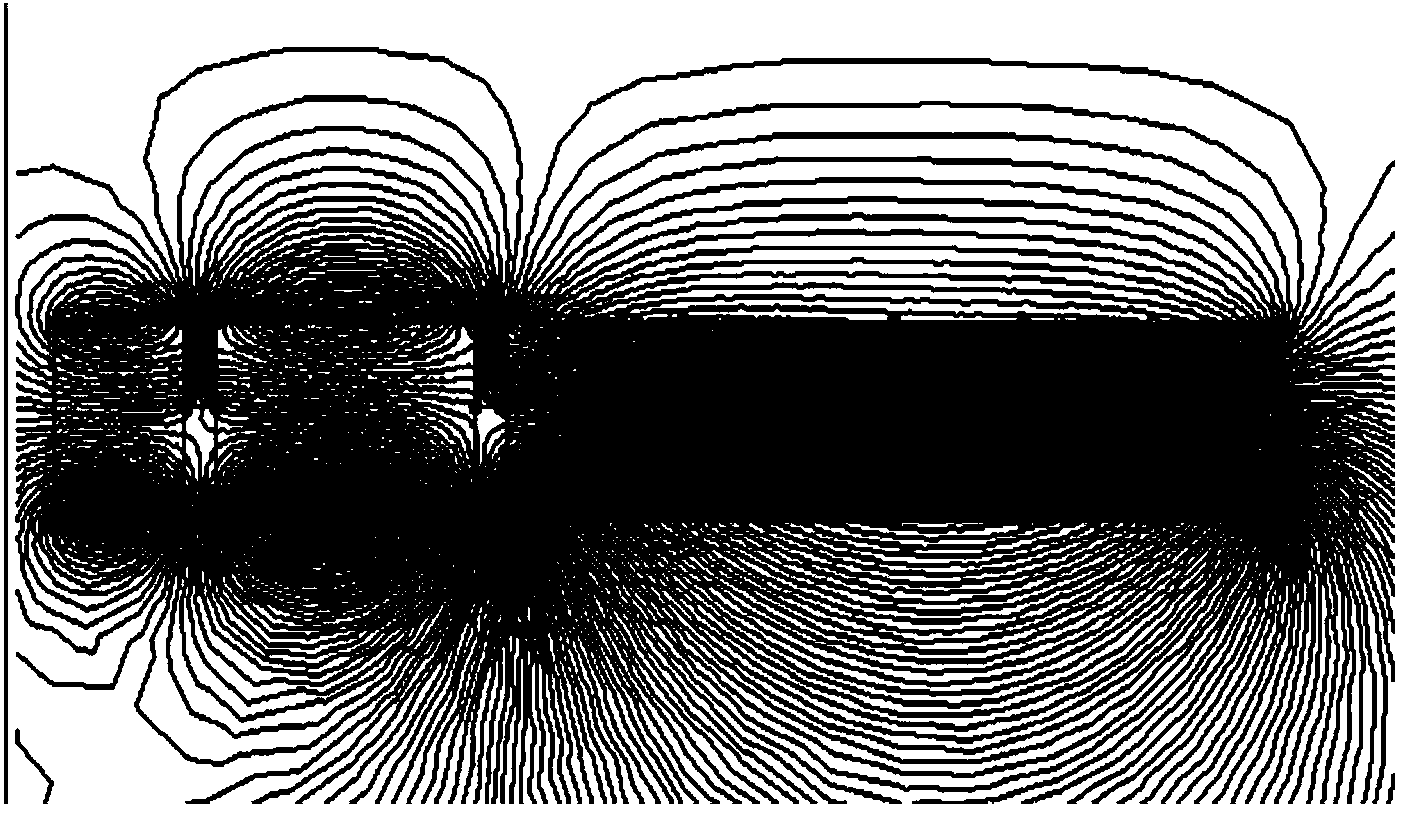

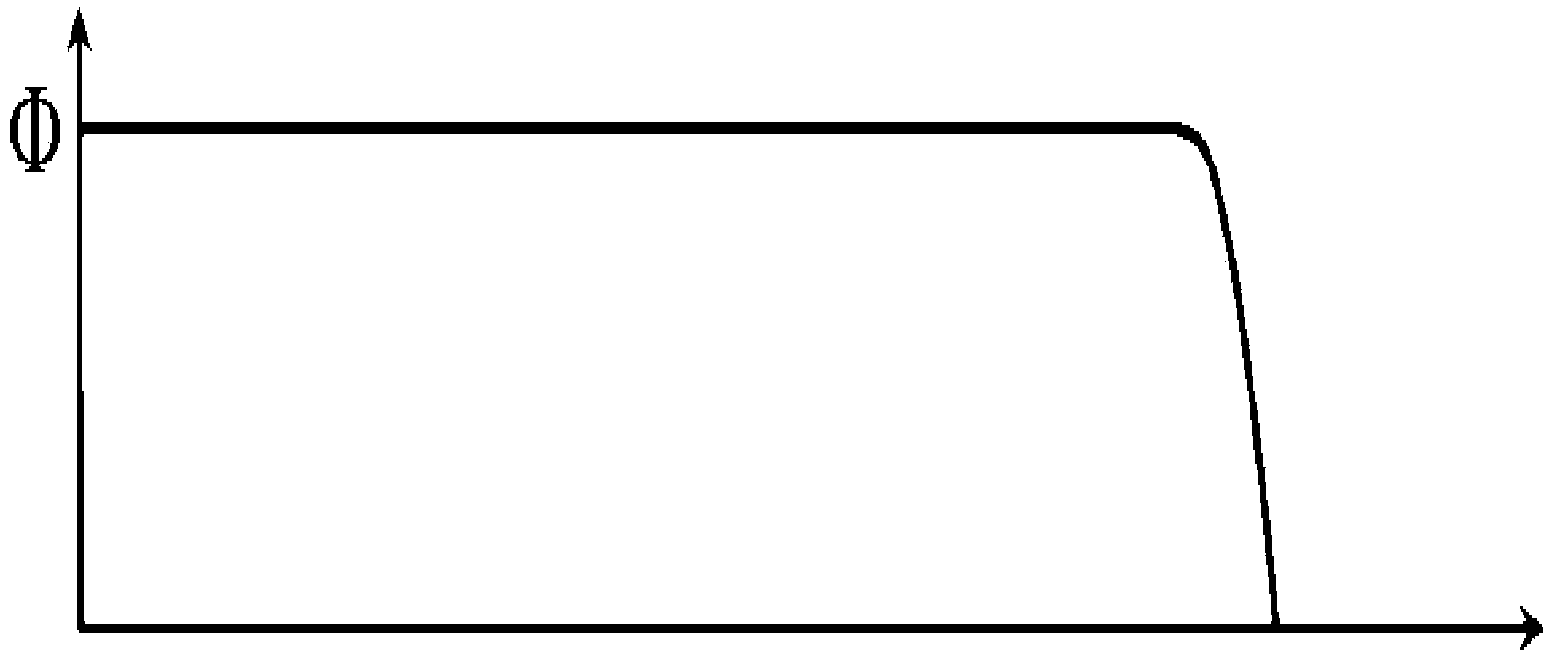

[0029] In the present embodiment, the number of the annular permanent magnets 5 is equal to 3, which is a three-stage permanent magnet structure, and the three annular permanent magnets 5 are respectively socketed in the front section A, Outer side of midsection B and posterior section C. The confinement of electrons is mainly to be controlled by the oscillation of the tip magnetic mirror that forms the magnetic tip between adjacent two ring-shaped permanent magnets 5, and the periodic ring-shaped permanent magnet 5 can form a tangential magnetic field, and at the magnetic tip, the magnetic field mainly is the radial direction, electrons are effectively hindered due to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com