Thin film microcircuit cutting method based on sacrificial layer

A thin-film circuit and sacrificial layer technology, which is applied in printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problem that the thin-film circuit is easily detached from the UV film and is washed away by the cooling liquid, the edge of the substrate is cracked, and the adhesion of the thin-film circuit is small. and other problems, to achieve the effect of reducing ceramic cracking, rapid response, and accelerated corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

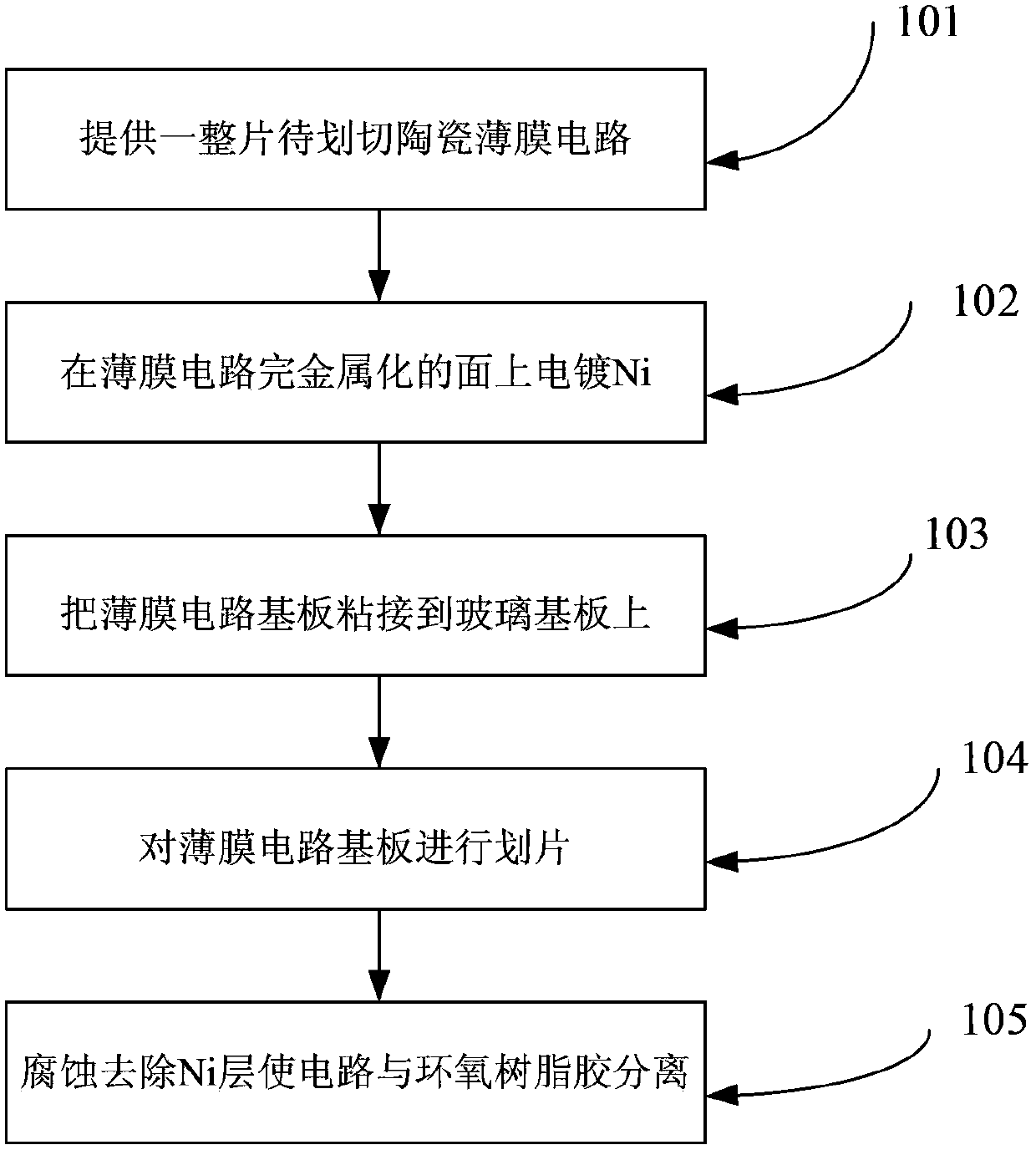

Method used

Image

Examples

Embodiment 1

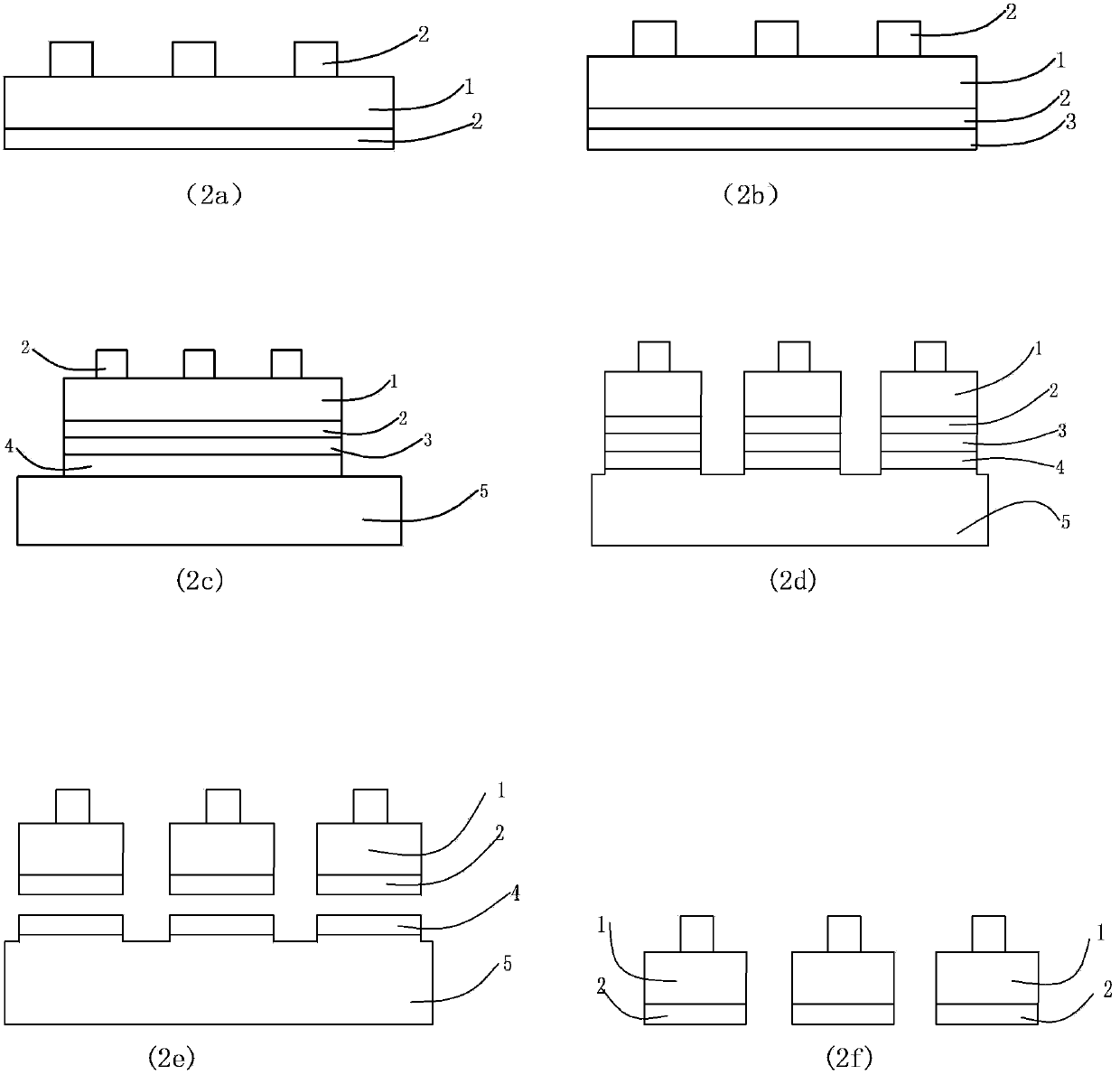

[0043]First, provide a whole piece of thin-film circuit with a ceramic substrate, at least one side of which is completely metallized by Au; the substrate material is alumina ceramic with a purity of 99.6%, and the thickness is 0.254mm. for the circuit diagram;

[0044] Electroplate a layer of Ni on the fully metallized surface of the above thin film circuit substrate by electroplating, and electroplate a layer of Ni with nickel sulfamate nickel plating solution, the circuit density is 10mA / cm 2 , the thickness of electroplated Ni layer is 0.5μm;

[0045] Prepare a clean glass substrate, choose the epoxy resin glue to bond the ceramic thin film circuit substrate on the side coated with the Ni layer to the glass substrate, keep the bonded thin film circuit substrate and the glass substrate at a level, and fully squeeze out the epoxy resin glue The remaining air bubbles in the epoxy resin can be fully cured at room temperature. Here, it can also be put into an oven to quickly c...

Embodiment 2

[0053] The difference from Example 1 is that the thickness of the electroplated Ni layer is 0.8 μm, and the stepping speed of 0.5 mm / s is selected for scribing, so as to reduce the force of the scribing knife on the substrate and thereby reduce the warping of the conductive band at the edge of the circuit , Reduce cracking of thin film circuit ceramic substrates.

Embodiment 3

[0055] The difference from Example 1 is that the thin film circuit substrate material is an aluminum nitride substrate with a purity of 98%, and the thickness of the substrate is 0.1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com