A kind of preparation method of immobilized alkaline ionic liquid catalyst

A technology of liquid catalysts and basic ions, applied in physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve high cost, low catalyst activity, difficult recovery, etc. problems, and achieve the effects of reducing preparation costs, high catalyst activity, and no pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

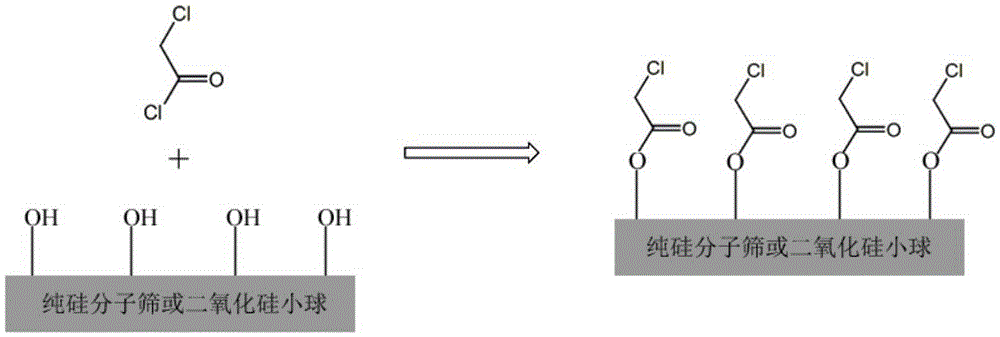

[0027] (1) Add toluene, pure silicon molecular sieve MCM-41 and chloroacetyl chloride in sequence in a round bottom flask, wherein the mass ratio of pure silicon molecular sieve MCM-41 to toluene is 1:30, pure silicon molecular sieve MCM-41 and chloroacetyl chloride The mass ratio is 8:1. Magnetically stirred and reacted at -10°C for 6 hours to obtain pure silicon molecular sieves with esterified hydroxyl groups on the surface.

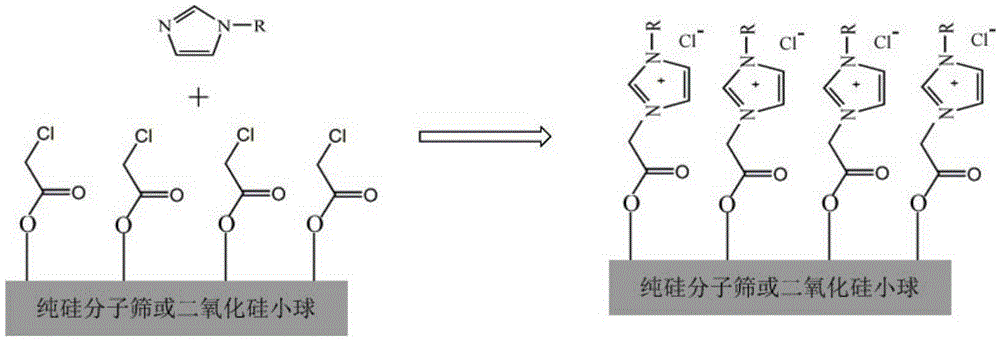

[0028] (2) After filtering, washing and drying the reaction system obtained in step (1), put the obtained solid into a dry round bottom flask, and then add toluene and 1-methylimidazole in sequence, wherein the mass of toluene and solid The ratio is 10:1, the mass ratio of 1-methylimidazole to solid is 0.2:1, heated to 60°C with magnetic stirring for 6 hours, and the immobilized ionic liquid with pure silicon molecular sieve as carrier can be obtained.

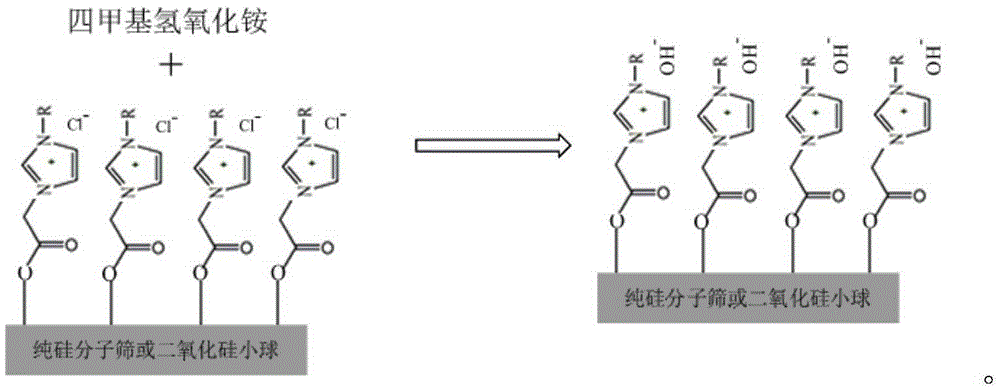

[0029] (3) Add the immobilized ionic liquid obtained in step (2) into a round-bottomed flask, and...

Embodiment 2

[0031] (1) Add toluene, pure silicon molecular sieve MCM-48 and chloroacetyl chloride in sequence in a round bottom flask, wherein the mass ratio of pure silicon molecular sieve MCM-48 to toluene is 1:30, pure silicon molecular sieve MCM-48 and chloroacetyl chloride The mass ratio is 8:1. The reaction was carried out under magnetic stirring at 30° C. for 6 hours to obtain a pure silicon molecular sieve with esterified hydroxyl groups on the surface.

[0032] (2) After filtering, washing and drying the reaction system obtained in step (1), add the obtained solid into a round bottom flask, and then add toluene and 1-methylimidazole in sequence, wherein the mass ratio of toluene to solid is 10 : 1, The mass ratio of 1-ethylimidazole to solid is 0.5:1, heated to 100° C. for 6 hours with magnetic stirring, and the immobilized ionic liquid with pure silicon molecular sieve as carrier can be obtained.

[0033] (3) Add the immobilized ionic liquid obtained in step (2) into a round bo...

Embodiment 3

[0035] (1) Add toluene, pure silicon molecular sieve SBA-15 and chloroacetyl chloride in sequence in a round bottom flask, wherein the mass ratio of pure silicon molecular sieve SBA-15 to toluene is 1:30, pure silicon molecular sieve SBA-15 and chloroacetyl chloride The mass ratio is 8:1. The reaction was carried out under magnetic stirring at 10° C. for 6 hours to obtain pure silicon molecular sieves with esterified hydroxyl groups on the surface.

[0036] (2) After filtering, washing and drying the reaction system obtained in step (1), add the obtained solid into a round bottom flask, and then add toluene and 1-propylimidazole in sequence, wherein the mass ratio of toluene to solid is 10 : 1, The mass ratio of 1-propylimidazole to solid is 0.3:1, heated to 100° C. for 6 hours with magnetic stirring, and the immobilized ionic liquid with pure silicon molecular sieve as carrier can be obtained.

[0037] (3) Add the immobilized ionic liquid obtained in step (2) into a round bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com