Treatment method of industrial wastewater in silicon wafer mortar recovery

A technology for industrial wastewater and treatment methods, which is applied in ceramic wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as lack of water resources, and achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

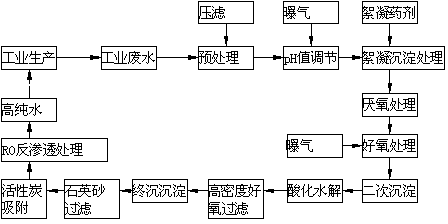

[0022] Embodiment 1 A kind of industrial wastewater treatment and resource recycling method, see figure 1 , including the following steps:

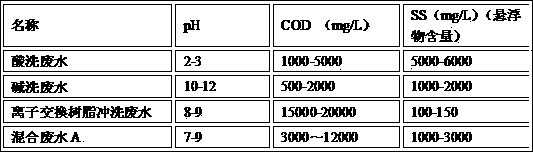

[0023] (1) Wastewater pretreatment: collect and store the pickling wastewater, alkali washing wastewater and ion exchange resin washing wastewater generated during the recycling process of crystal silicon cutting waste mortar, and then separate the pickling wastewater, alkali washing wastewater and ion exchange resin Washing wastewater is mixed to obtain mixed wastewater A. The volume ratio of the acid washing wastewater, alkali washing wastewater and ion exchange resin washing wastewater is 1:0.5~1:1~1.5, for example: pickling wastewater, alkali washing wastewater and ion exchange The volume ratio of resin washing wastewater is 1:0.5:1, the volume ratio of pickling wastewater, alkali washing wastewater and ion exchange resin washing wastewater is 1: 1: 1.5, the volume ratio of pickling wastewater, alkali washing wastewater and ion exchan...

Embodiment 2

[0038] Example 2 The method and steps of this example are basically the same as in Example 1, except that the reagent used in the flocculation and sedimentation treatment is a mixture of coagulant polyaluminum chloride and polyferric sulfate flocculant, and the coagulant is polymerized The quality of aluminum chloride accounts for 0.1 to 0.3% of the quality of mixed wastewater A, such as 0.1%, 0.2%, and 0.3%. The mass of polyferric sulfate accounts for 0.01-0.03% of the mass of mixed wastewater A, such as 0.01%, 0.02%, and 0.03%.

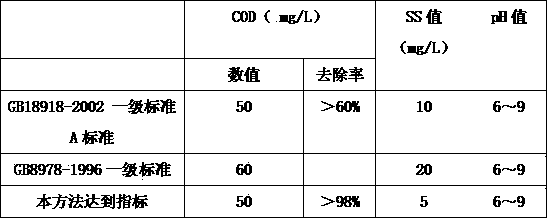

[0039] The design of this industrial wastewater treatment system is carried out according to the characteristics of the recycling industry of crystal silicon cutting waste mortar, including pretreatment of the system, pH value adjustment, flocculation and sedimentation treatment, anaerobic, aerobic, acid hydrolysis, high-density aerobic A series of processes such as filtration, flocculation and bottom treatment, secondary sedimentation, final sedime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com