Zirconium Niobium Alloys for Reactor Nuclear Fuel Assemblies

A technology for nuclear fuel assemblies and zirconium-niobium alloys, which is applied in the field of zirconium-niobium alloys, can solve the problems of high corrosion resistance, high fuel consumption, failure of fuel rod cladding structure, deviation from nucleate boiling, etc., and achieves low cost and high yield. , reduce the effect of corrosion and weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Several different preferred embodiments of the present invention will be described below.

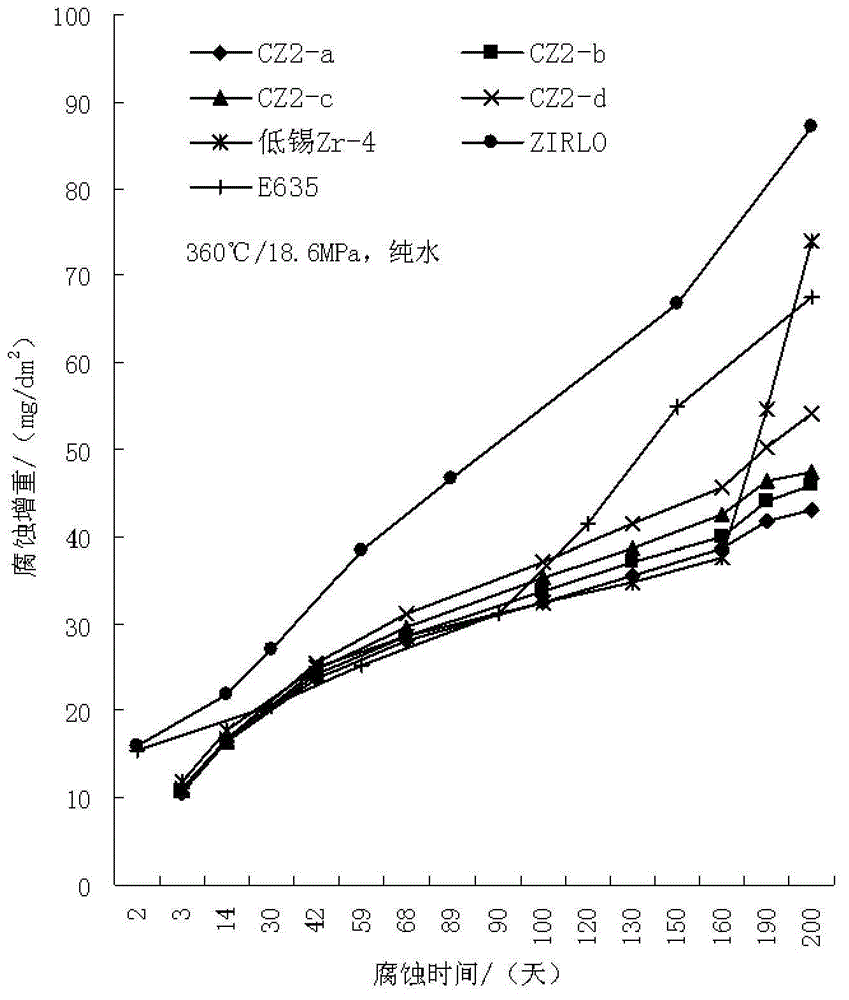

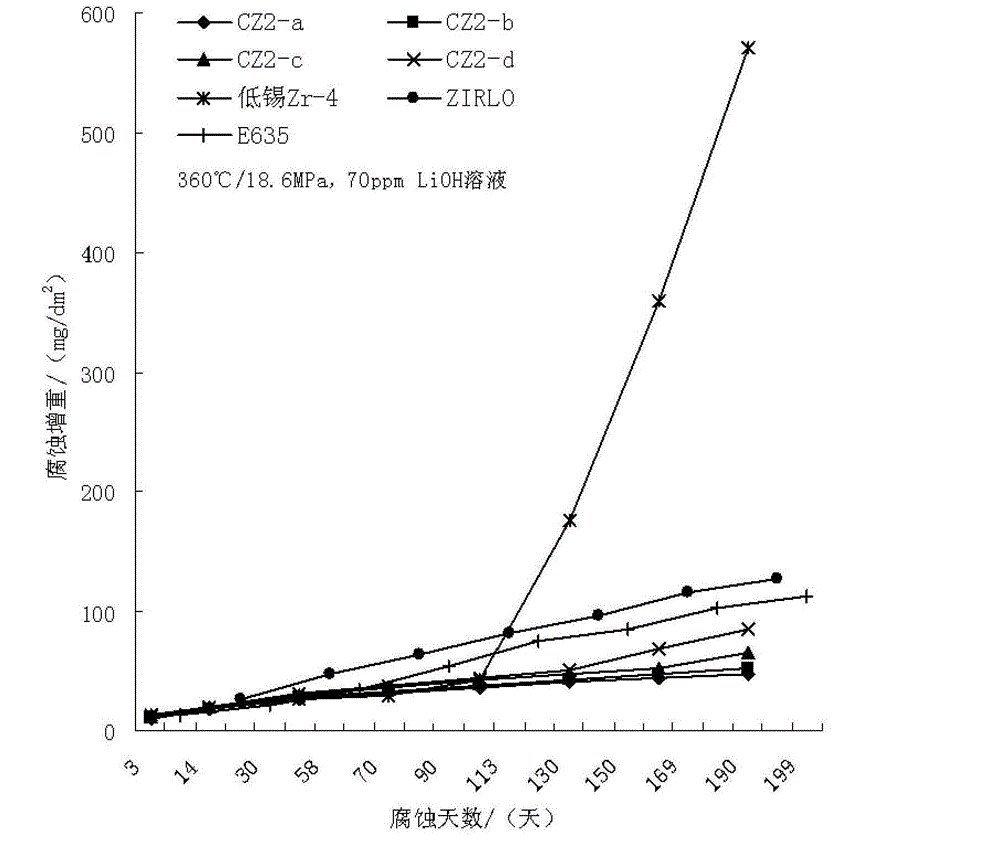

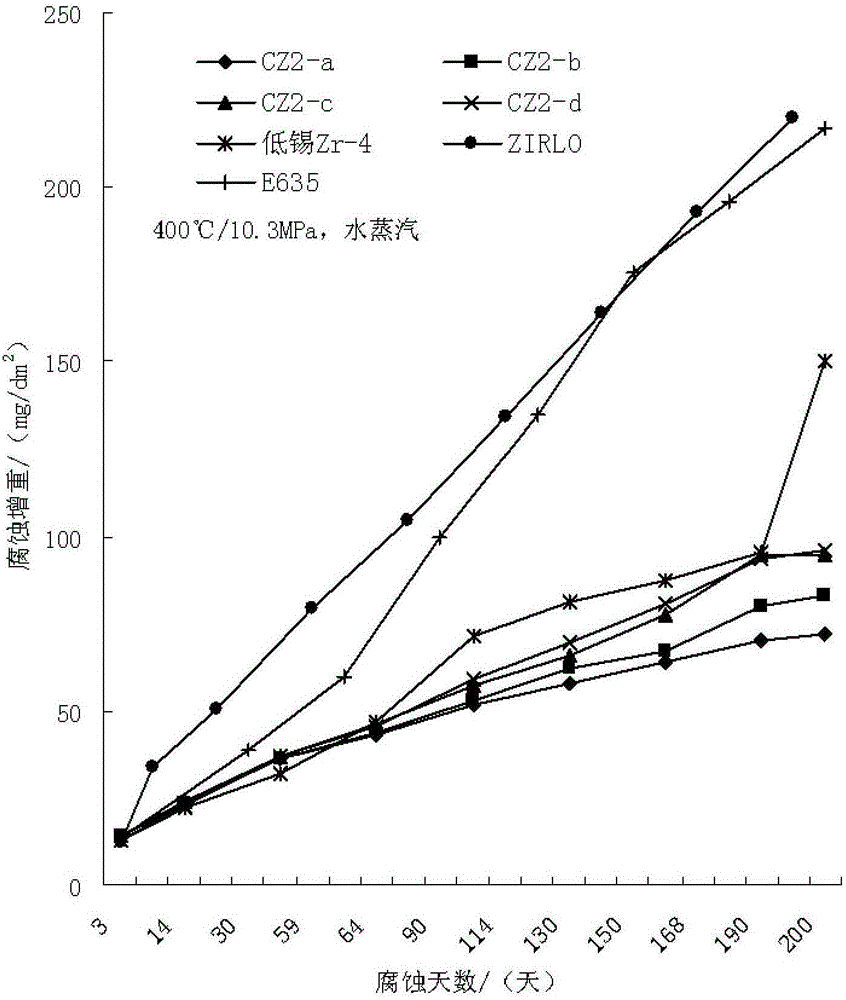

[0023] The essence of the present invention is to provide a zirconium-niobium alloy for reactor nuclear fuel assembly, which includes the following components based on the weight percentage of the zirconium-niobium alloy: 0.9% to 1.1% of Nb, 0.15% to 0.35% of Fe, and 0.1% ~0.16% O, and 0.004%~0.01% Cu, except for unavoidable impurities, the balance being Zr. Among them, Nb, Fe, O, and Cu are strengthening elements. In the present invention, the strengthening effect brought by these strengthening elements is sufficient, otherwise the zirconium-niobium alloy will be significantly strengthened and its toughness will be reduced, and it will be easy to crack during the extrusion process of the tube blank This leads to a decrease in the yield of good products, or even damage to equipment, so the content of each strengthening element in the zirconium-niobium alloy of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com