Plastic micro-channel pipeline structure, and preparation method and device thereof

A technology for preparing devices and microchannels, which is applied in the directions of hoses, pipes, mechanical equipment, etc., can solve the problems of complex manufacturing process and high cost, and achieve enhanced mass transfer and heat transfer performance, high production efficiency, and convenient secondary molding. and the effect of large-scale integrated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

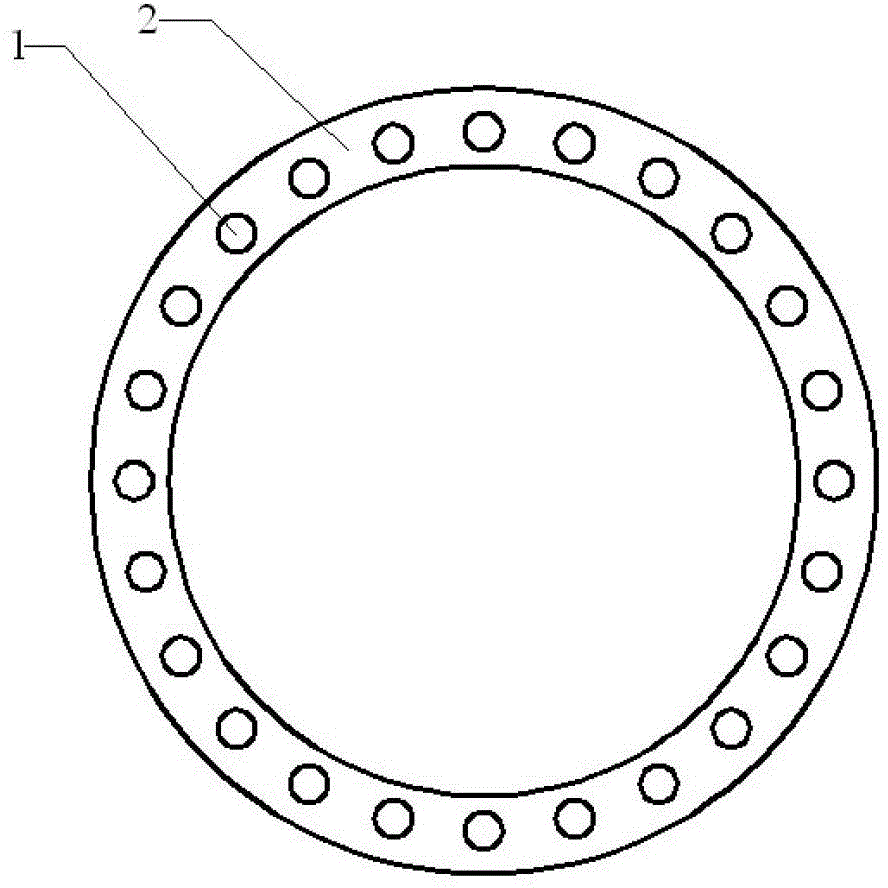

[0030] Such as figure 1 As shown, the plastic microchannel pipeline structure (MCT) of the present invention is a hollow pipeline, and a plurality of microchannels 1 are evenly arranged along the circumference around the central through hole on the pipeline wall 2, and the arrangement form can be changed according to specific application requirements by replacing the injection needle module. achieved.

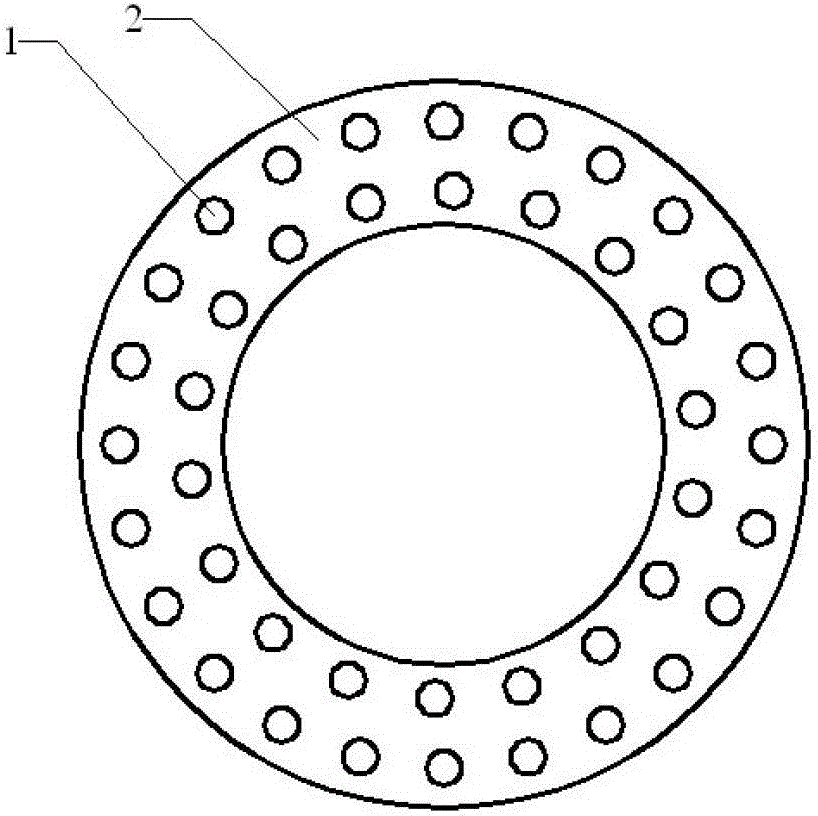

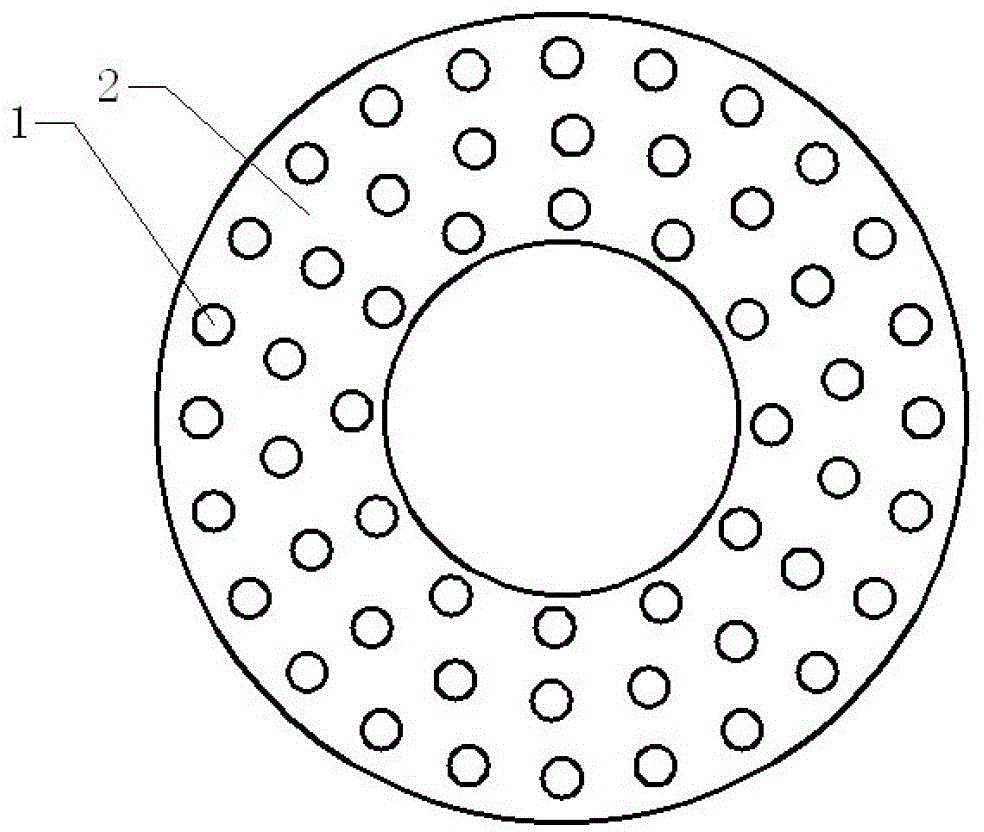

[0031] Such as figure 2 As shown, a plurality of microchannels 1 are evenly arranged on the circumference of two different radii concentric with the central through hole in the pipeline wall 2; or as image 3 As shown in a more complex form, a plurality of microchannels 1 are uniformly arranged on three circumferences with different radii concentric with the central through hole in the pipe wall 2 .

[0032] The outer diameter of the microchannel pipe structure of the present invention is 1~5mm, the wall thickness of the pipe is 0.05~1mm, and the average microchannel diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com