Detection method and test device for catalytic properties of heatproof material based on emission spectrum

A heat-resistant material and emission spectrum technology, which is applied in the field of detection methods and test devices for the catalytic properties of heat-resistant materials, can solve the problems that state parameters cannot be changed independently, high operating costs, and many interference factors that require flow field reconstruction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

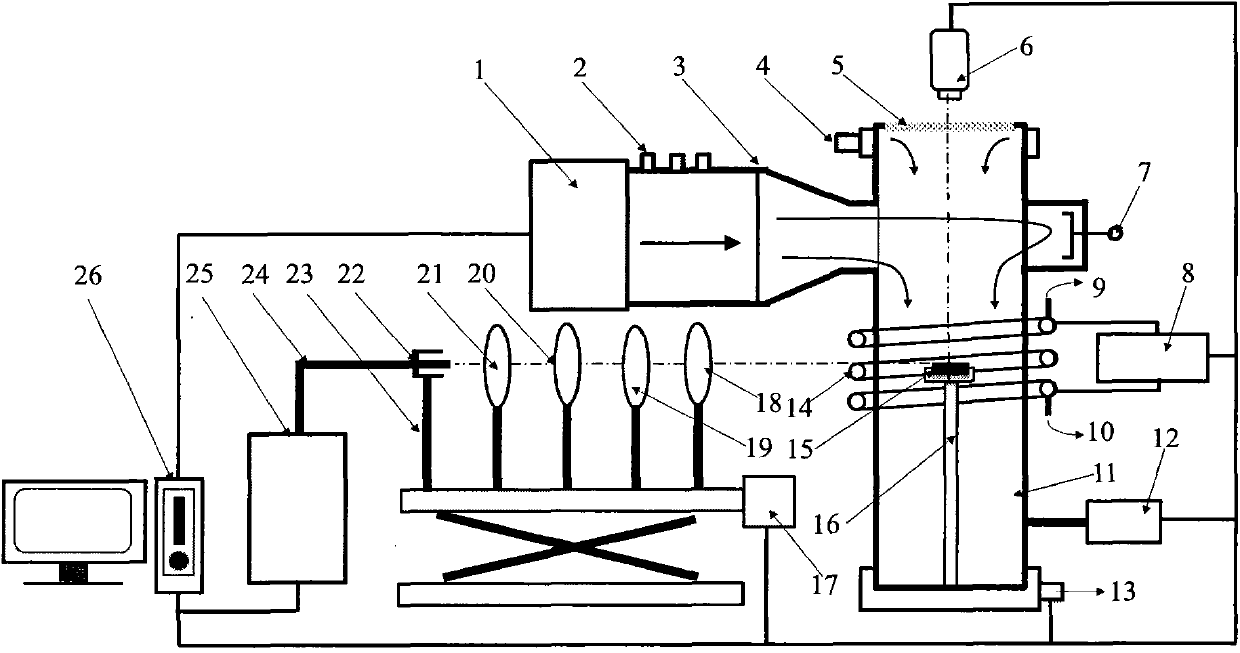

Embodiment 1

[0062] A high-temperature and low-pressure heat-resistant material surface catalytic performance testing device, including a plasma power supply 1, one end of a waveguide transmission device 3 is output from the plasma power supply, and the other end is connected to a resonant cavity, and is adjusted by controlling the output power of the power supply and the three screws on the waveguide transmission device 3 The emitter 2 and the launch piston 7 outside the resonant cavity adjust the output energy and then adjust the plasma intensity. The oxygen and argon are connected to the intake valve 4 from the gas cylinder through a pressure reducing valve, a stop valve, a solenoid valve, and a flow meter. The temperature window 5 and the double colorimetric thermometer 6 test the surface temperature of the sample 15 below the axis through the infrared temperature measurement window 5. The temperature data is transmitted to the computer 26 and stored. The lower end of the resonance cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com