A method of manufacturing a rectangular conductor with a large ampacity and a low temperature rise

A technology for rectangular conductors and manufacturing methods, which is applied in the direction of cable/conductor manufacturing, conductors, insulated conductors, etc., can solve the problems of reducing current carrying capacity, large discharge current capacity, and temperature rise, and achieves improved current carrying capacity, large current carrying capacity, and high temperature. The effect of lowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

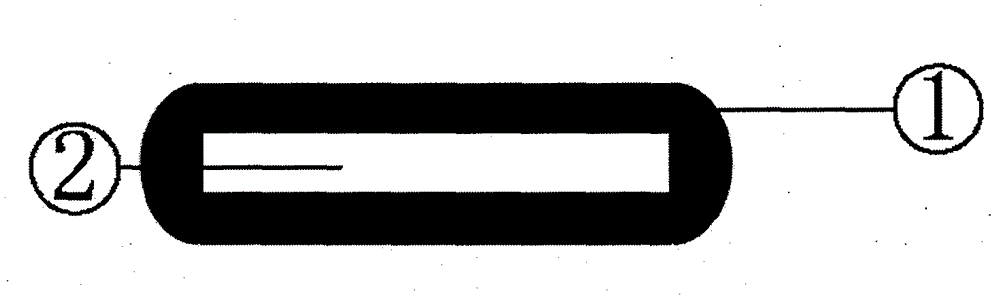

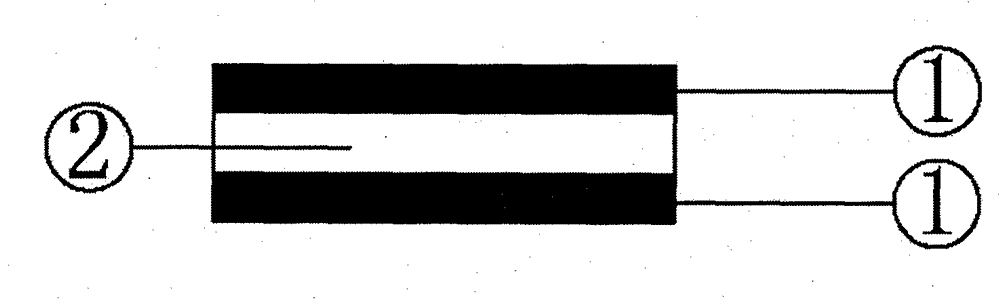

[0016] Such as figure 1 Shown, a kind of rectangular conductor of the present invention, the method of making: method one: keep the body oxide layer of copper sleeve and aluminum alloy rod, copper sleeve is enclosed within on the aluminum alloy rod [the wall thickness of copper sleeve is determined according to the electric current size ( 0.1mm—10mm), the diameter of the aluminum alloy rod depends on the current (1mm—100mm)], the aluminum alloy rod with the copper sleeve is pressed into the copper sleeve (1) and the aluminum alloy row (2) through the rolling machine; method 2: keep The body oxide layer of the copper sleeve and the aluminum alloy rod is evenly covered on the aluminum alloy rod with copper strips, the seam of the copper strip is welded into a copper sleeve, and the copper sleeve aluminum alloy rod is pressed into the copper sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com