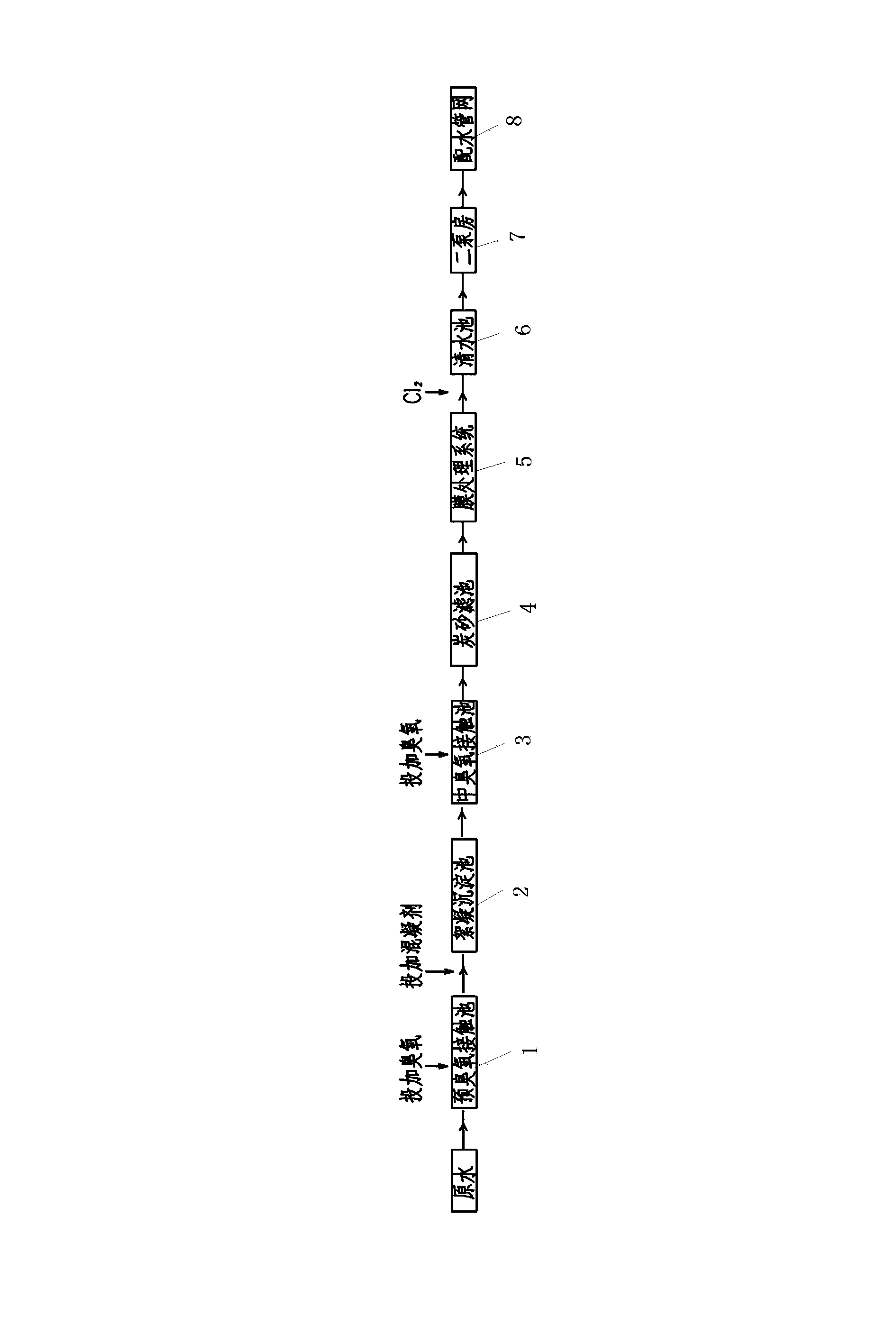

Combined processing technology for slightly polluted raw water

A micro-pollution and process technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Problems such as the limited storage capacity of Qingshui Reservoir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

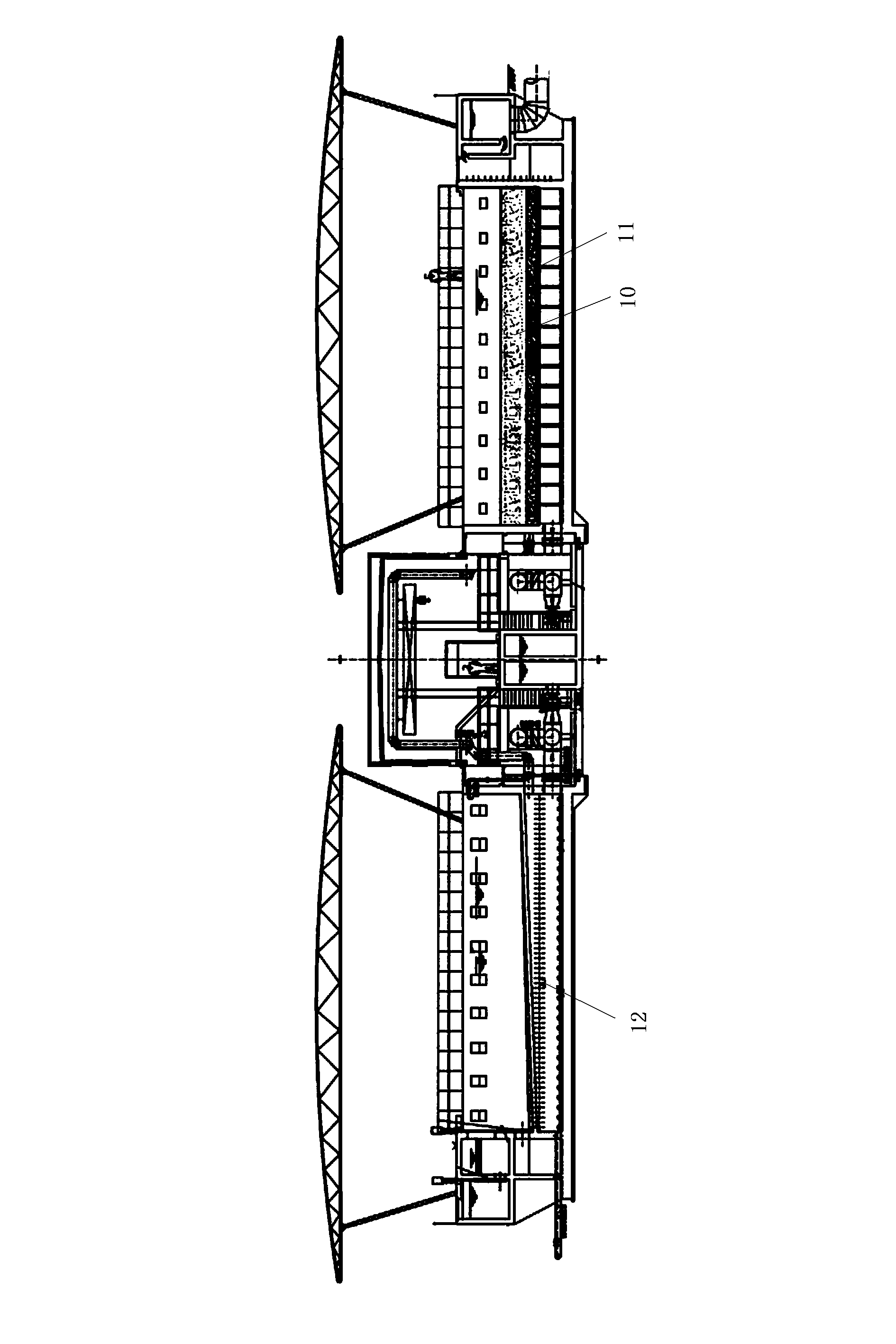

[0012] As shown in the figure, a combined strengthening device for slightly polluted raw water includes pre-ozone contact tank 1, flocculation sedimentation tank 2, medium ozone contact tank 3, biochar sand filter 4, membrane treatment system 5, clear water Pool 6, pump room 7 and water distribution pipe network 8.

[0013] The purpose of intensifying pre-ozone is mainly to meet the technical needs of the subsequent installation of biochar sand filters, and to replace the coagulation aiding effect of pre-chlorination commonly used in conventional treatment processes, so as to avoid the phenomenon of excessive halogenated substances caused by chlorine addition and the impact on biochar sand. Adverse effect on the biological action of the filter. And effectively oxidize manganese to create conditions for improving the efficiency of manganese removal by precipitation. At the same time, it can also increase the dissolved oxygen in water and create conditions for the carbon sand f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com