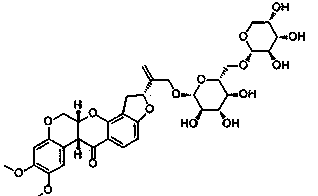

Preparation method for amorpha fruticosa glycosides

A technology of amorphoside and amorphaside, which is applied in the field of natural medicinal chemistry and can solve the problems of disclosure and no industrialization method of amorphaside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 5kg of raw materials of Amorpha fruticosa fruit and crush them, add 1000ml of water and 10g of amylase to enzymatically hydrolyze for 20 hours, add 7 times the amount of 70% ethanol solution to the enzymatically hydrolyzed raw materials and extract twice, dilute the concentrated solution with appropriate amount of water and add ADS-21 macropore Adsorbed in the resin, first use 5 times the column volume of 40% ethanol solution to elute the impurities, then use 10 times the column volume of 50% ethanol to elute the active ingredient, add an appropriate amount of 30% ethanol solution to dissolve the concentrated solution, and add it to ADS-21 macroporous resin Adsorption, elute impurities with 6 times column volume of 30% ethanol solution, then elute with 8 times column volume of 55% ethanol, collect the eluate and concentrate it under reduced pressure until it is anhydrous and place it to crystallize, filter the crystals and dissolve the weight in ethyl acetate Crysta...

Embodiment 2

[0019] Take 5kg of Amorpha fruticosa raw material and crush it, add 1000ml of water and 13g of cellulase to enzymolyze it for 10 hours, add 6 times the amount of 60% ethanol solution to the enzymatic hydrolysis raw material, reflux and extract it for 3 times, dilute the concentrated solution with appropriate amount of water and add AB-8 large Adsorbed in the porous resin, first use 10 times column volume 20% ethanol solution to elute impurities, then use 7 times column volume 70% ethanol to elute active ingredients, add appropriate amount of 30% ethanol solution to dissolve the concentrated solution, add AB-8 macroporous resin Adsorb in medium, elute impurities with 6 times column volume of 30% ethanol solution, then elute with 8 times column volume of 55% ethanol, collect eluate and concentrate under reduced pressure until anhydrous and place crystallization, filter crystals and dissolve them in ethyl acetate Recrystallized and dried at low temperature to obtain 28 g of a...

Embodiment 3

[0021] Take 5kg of raw materials of Amorpha fruticosa fruit and crush them, add 1000ml of water and 20g of pectinase to enzymatically hydrolyze for 5 hours, add 7 times the amount of 90% ethanol solution to the enzymolyzed raw materials and extract them for 3 times, dilute the concentrated solution with appropriate amount of water and add HZ816 macroporous resin Adsorption in medium, first use 6 times column volume 30% ethanol solution to elute impurities, then use 6 times column volume 70% ethanol to elute active ingredients, add appropriate amount of 30% ethanol solution to dissolve the concentrated solution, add it to HZ816 macroporous resin for adsorption, use 6 times the column volume of 30% ethanol solution to elute the impurities, and then 8 times the column volume of 55% ethanol to elute, collect the eluate and concentrate it under reduced pressure until it is anhydrous and place it to crystallize, the crystals are filtered out and recrystallized with ethyl acetate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com