Preparation method and application of functional water-based heat-radiative color paint

A multi-color paint, heat radiation technology, applied in the direction of multi-color effect paint, coating, etc., to achieve the effect of excellent heat insulation and excellent decorative performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Continuous phase (white): Add 35 parts of water and 0.5 parts of hydroxyethyl cellulose in sequence in the dispersion tank, adjust the speed to 350rpm, then increase the speed to 1000rpm, add 15 parts of infrared powder, disperse and stir for 15min, then reduce the speed Adjust to 600rpm, add 2 parts of Texanol, stir for 5 minutes, slowly add 45 parts of EVA emulsion, 2 parts of metal ion solution, 0.5 parts of antifungal agent, stir evenly and disperse for 10 minutes, then seal and store;

[0024] Dispersed phase (white): Add 27 parts of water, 0.5 parts of BR3 wetting and dispersing agent, 0.5 part of 7010 defoamer to the dispersion tank in turn, stir at 300rpm, add 20 parts of infrared powder; increase the speed to 1200rpm, disperse Stir for 15 minutes; adjust the speed to 800rpm, add 2 parts of carboxymethyl cellulose, stir for 5 minutes, then slowly add 50 parts of EVA emulsion, stir well and set aside;

[0025] Dispersed phase (black): Add 39 parts of water, 0.5 p...

Embodiment 2

[0029] The dispersed phase (white) and the dispersed phase (black) are prepared by the method of Example 1, and the dispersed phase (red) only needs to replace silicon carbide and graphene with iron oxide and zirconia; the continuous phase (white) also adopts Example 1 prepared by the method;

[0030] Finished product: add 70 parts of continuous phase to the dispersion tank, stir at low speed, slowly add 10 parts of dispersed phase (white), 10 parts of dispersed phase (black), and 10 parts of dispersed phase (red) until the particle diameter reaches the requirement That's it.

Embodiment 3

[0032] Dispersed phase (white), dispersed phase (black) and dispersed phase (gray) are prepared by the method of Example 1, the continuous phase (white) only needs to replace the infrared powder with silicon carbide, and the carbon fiber tube filler adopts the method of Example 1 preparation;

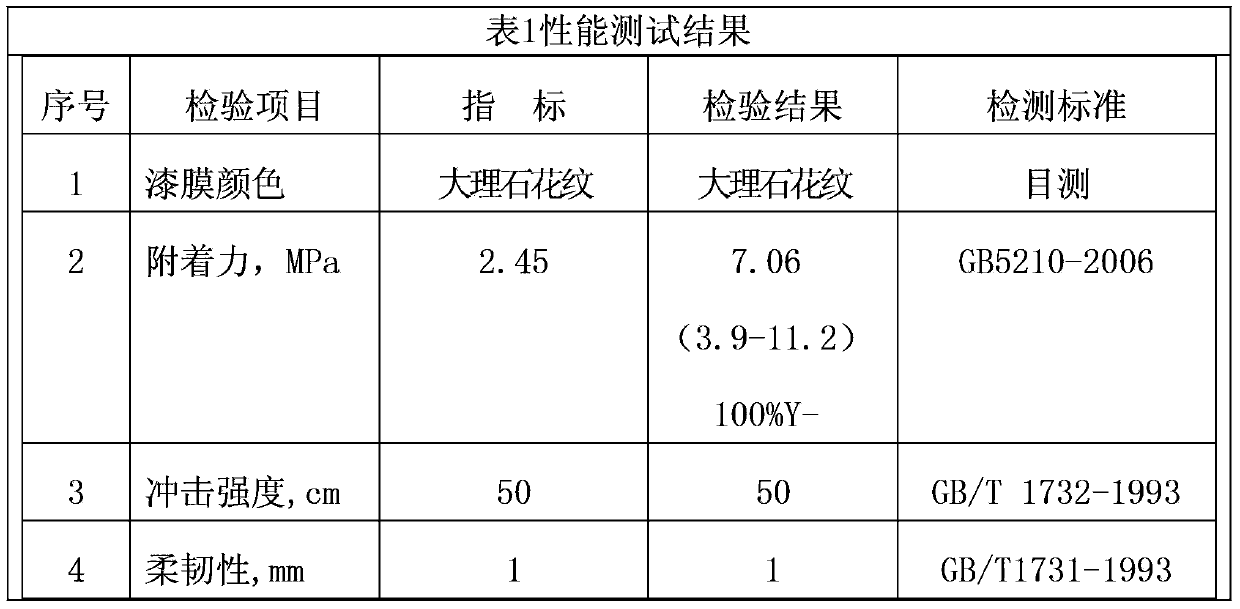

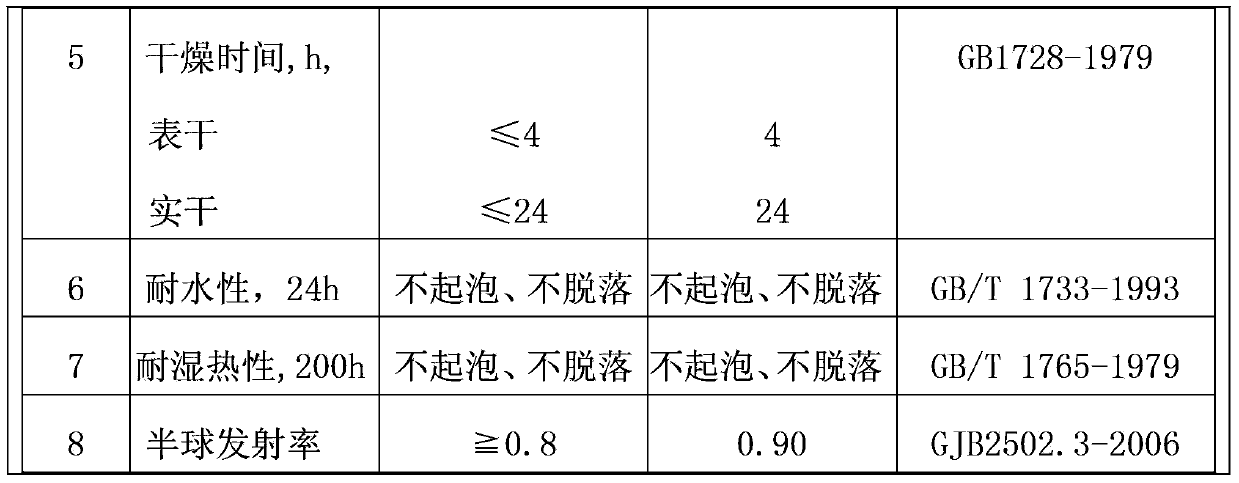

[0033] Finished product: Add 80 parts of the continuous phase to the dispersion tank, stir at low speed, slowly add 5 parts of the dispersed phase (white), 10 parts of the dispersed phase (black), and 5 parts of the dispersed phase (gray) until the particle diameter reaches the requirement That's it. The general performance test of the coating in the above examples, the emissivity is tested according to GJB2502.3-2006, and the specific results are shown in Table 1:

[0034]

[0035]

[0036] It can be seen from the above table that the water-based heat-radiating multi-color paint of the present invention has high water resistance, high humidity and heat resistance, beautiful surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com