Antibacterial spun-dyed yarn and colored spinning process of antibacterial spun-dyed yarn

A technology of color spinning and spinning, which is applied in the directions of yarn, textile, textile and paper making, can solve the problems of poor washing resistance and antibacterial durability, and high requirements for antibacterial agents, and achieves good antibacterial effect, excellent antibacterial performance, and durability. Good washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

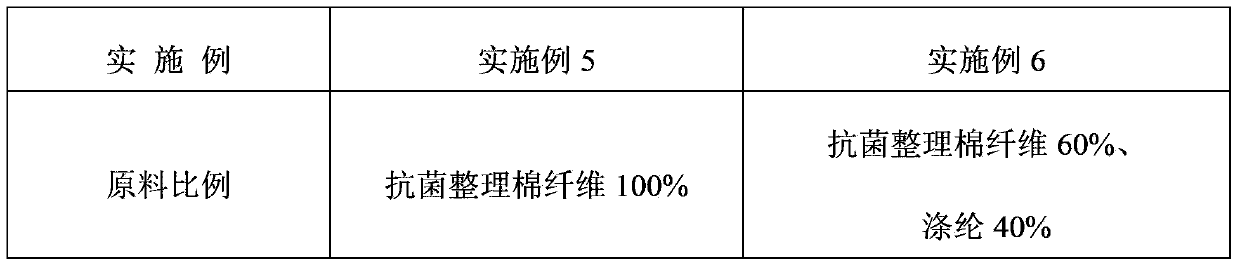

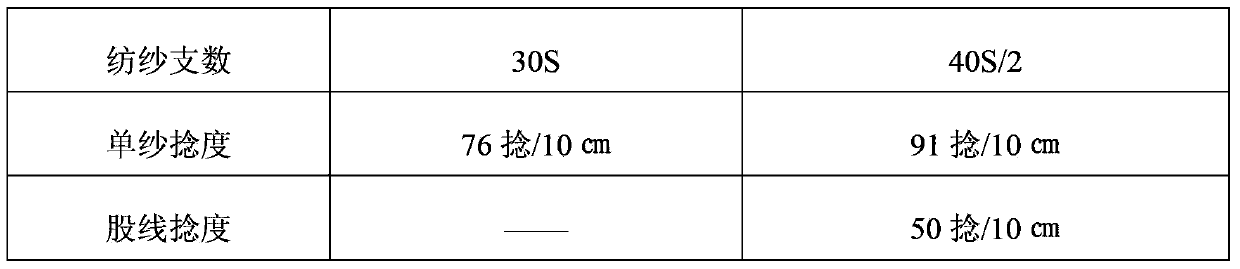

Examples

Embodiment 1

[0068] Bleaching and antibacterial finishing process of cotton fiber:

[0069] Weigh 140 kg of cotton loose fiber, put it into a cage, and then put it into an aqueous solution with a bath ratio of 1:10 at room temperature, add penetrating agent JFC2.0%~5.0wt%, refining agent SA1.0%~3.0wt% 1. Raising agent ERKANTOL NR1.0%~3.0wt%; use soda ash or flake soda to adjust the pH value of the solution to 10~11, and raise the temperature to 80℃~90℃ at 3℃ / min, and add hydrogen peroxide at 60℃, hydrogen peroxide The addition amount of the water is 10g / L; after running for 20min~60min, drain the foot water; wash once, add deoxygenase 0.5%~4.0wt% when washing, add 2.0%~5.0wt% acetic acid after running at 50°C for 10min, and Run at 60°C for another 20min to 30min, and wash twice with water.

[0070] Add 0.5%-5.0wt% wetting and penetrating agent at room temperature, adjust the pH value to 4.5-6.0 with acetic acid or citric acid, add antibacterial finishing agent Sanitized T25-25Silver 2.0%-...

Embodiment 2

[0072] Natural white antibacterial finishing of non-cotton fibers: using chemical fibers

[0073] Weigh 180 kg of spandex loose fiber, put it into a cage, and then put it into a solution with a bath ratio of 1:10 at room temperature, add wetting and penetrating agent JFC2.0%~5.0wt%, antibacterial agent SCJ-9500.5%-5.0 wt%, softener CWS2.0%~5.0wt%, leavening agent GE2.0%~5.0wt%, antistatic agent TF480A2.0%~5.0wt%, then heat up at a rate of 1℃~3℃ / min To 50°C, and run for 20min-50min, then cool down at a rate of 1-3°C / min, drain, dehydrate, and dry at 100-120°C.

Embodiment 3

[0075] Dyeing and Antibacterial Finishing of Cotton Fiber

[0076] Weigh 150 kg of cotton loose fiber, put it into a cage, put it into water with a bath ratio of 1:10 at room temperature, add wetting and penetrating agent JFC2.0%~5.0wt%, refining agent SA1.0%~3.0wt% , then use soda ash or caustic soda to adjust the pH value of the solution to 10-11, then raise the temperature to 50-80°C at 3°C / min, and run for 20-60min, drain the foot water, and then wash once;

[0077] Reactive dyes are used, and the dye formula is: 0.2wt% of 3BS red, 0.7wt% of 3RS yellow, and 1.5wt% of Yuanqing B; the dye is poured into the auxiliary vat of the dyeing vat, and the chemical material is put into the dyeing vat at 50°C for 10 minutes, and the temperature is maintained for 5 minutes. Add 1 / 5 yuan sodium starch powder to the auxiliary tank, clear water to convert the sodium starch powder, run for 10 minutes, add 2 / 5 yuan sodium starch powder every 10 minutes; then raise the temperature to 60 degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com