Flash memory cell and method of forming same

A flash memory cell and material layer technology, which is applied in the manufacture of electrical components, electric solid-state devices, and semiconductor/solid-state devices, etc., can solve the problems of low erasing and writing efficiency and low coupling efficiency of flash memory, and improve the erasing and writing performance and coupling efficiency. , the effect of increasing the capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

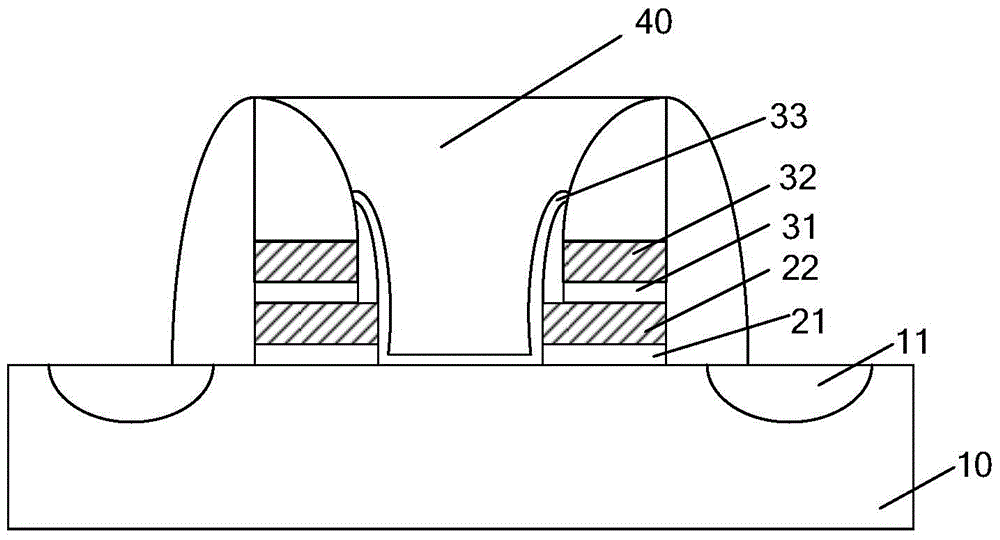

[0023] As mentioned in the background, the coupling efficiency of the control gate to the floating gate in the flash memory formed in the prior art is not high. Studies have found that this low coupling efficiency will cause the floating gate to be coupled with a low voltage from the control gate, resulting in the need to increase the voltage to a very high level when programming or erasing the flash memory, reducing the erasing efficiency of the flash memory, and reducing the performance of the flash memory. The consumption becomes larger, and the higher voltage will also increase the requirements for material reliability.

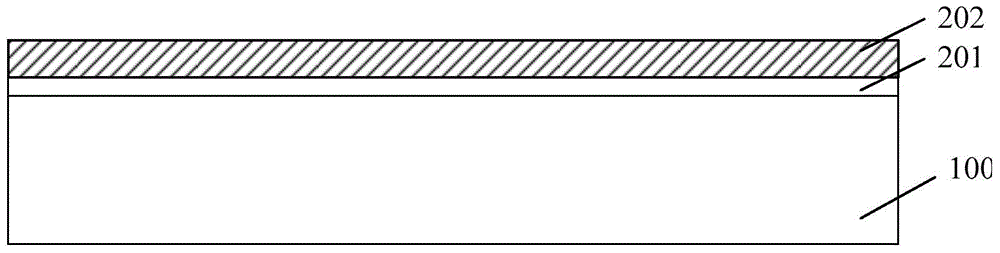

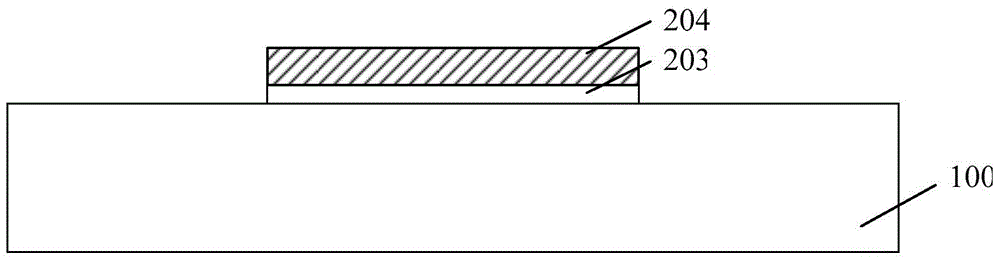

[0024] The control gate-to-floating gate coupling efficiency of a flash memory is the ratio of the capacitance between the control gate and the floating gate to the total capacitance around the floating gate. The control gate of the prior art flash memory is located above the top surface of the floating gate. The capacitance between the gates depends on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com