Internal cavity and external cavity mixing type non-linear frequency conversion ultraviolet laser

An ultraviolet laser and frequency conversion technology, which is applied in the field of lasers, can solve the problems of poor triple frequency stability, low double frequency efficiency, and low optical power density, so as to improve conversion rate, ensure long-term stability, and high power density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and examples.

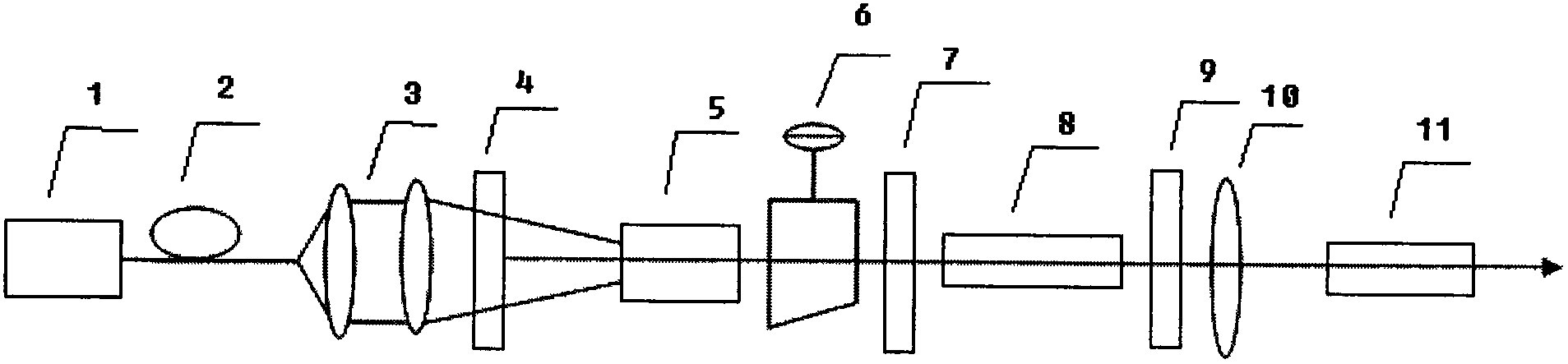

[0024] figure 1 It is the optical path diagram of the hybrid nonlinear frequency conversion ultraviolet laser with internal and external cavity of the present invention;

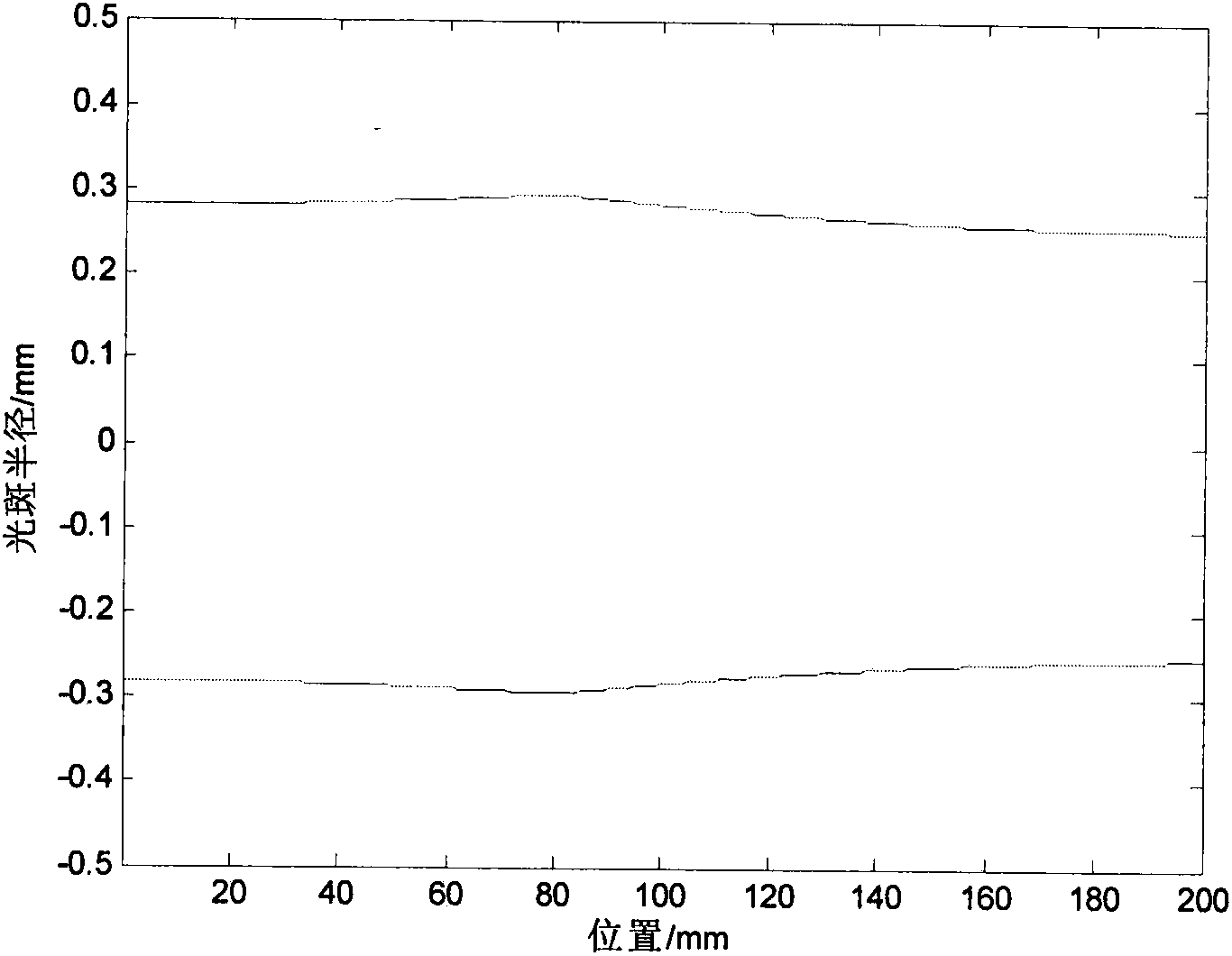

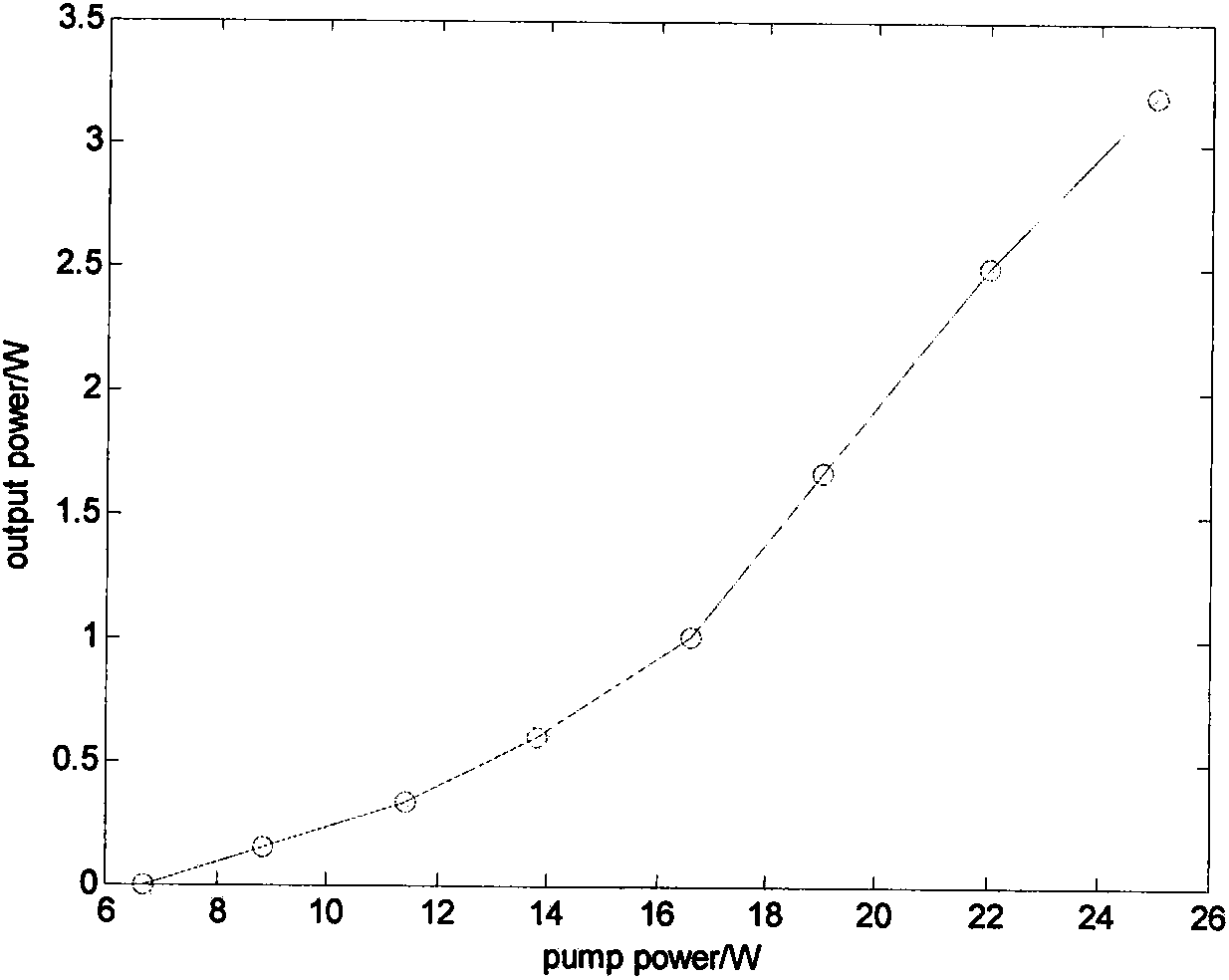

[0025] figure 2 It is a simulation relationship diagram of the resonant cavity stable region and the transmission beam in the hybrid nonlinear frequency conversion ultraviolet laser with internal and external cavity of the present invention; image 3 It is the relationship diagram of the output ultraviolet spot and the ultraviolet output power and the pumping power in the hybrid nonlinear frequency conversion ultraviolet laser with internal and external cavity of the present invention; Figure 4 It is a single pulse waveform diagram output by the hybrid nonlinear frequency conversion ultraviolet laser with internal and external cavity of the present invention.

[0026] Such as Figure 1 to Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com