Submersible linear motor liquid level measurement and control device

A technology of linear motors and measurement and control devices, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as difficulty in ensuring detection accuracy, failure to detect insulation of motors, and separate power lines for sensors, so as to improve service life and reduce failures rate, shortening the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

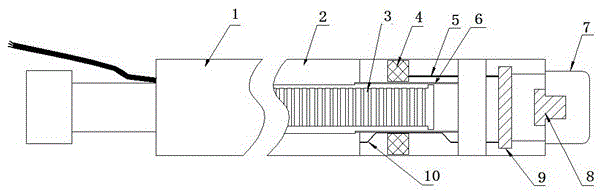

[0009] See figure 1 , the specific structure is as follows: at the outer ring of the tail pipe 6 of the submersible linear motor 1, a coil winding 4 with an iron core is placed near the lower end of the stator 2 of the submersible linear motor, and the coil winding 4 is connected to the rectifier through the sensor power cable 5 The circuit board 9 and the rectification circuit board 9 are connected to the pressure sensor 8 at the lowermost end, and the external assembly of the pressure sensor 8 balances the capsule 7 (the prior art).

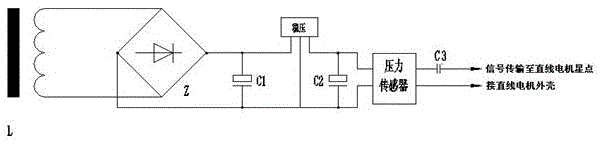

[0010] See figure 2 , The circuit principle of the measurement and control device: the AC voltage generated by the coil winding 4 (L) and the permanent magnet mover 3 of the submersible linear motor cutting the magnetic induction line is rectified into a DC voltage through the silicon bridge Z, and then passed through the capacitor C1, C2 filters and stores it to make it output a stable DC voltage, which is supplied to the pressure sensor 8 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com