Sanitary ware

A kind of pottery and sanitation technology, which is applied in the field of sanitary pottery and can solve the problems of easily damaged photocatalyst layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Although the present invention will be specifically described based on the following examples, the present invention is not limited to these examples.

[0038] In addition, since the evaluation of the durability (water resistance) of the photocatalyst layer formed on the surface of sanitary ware to water showed approximately the same tendency as the test for alkali resistance, the following alkali resistance test was used in this example to evaluate.

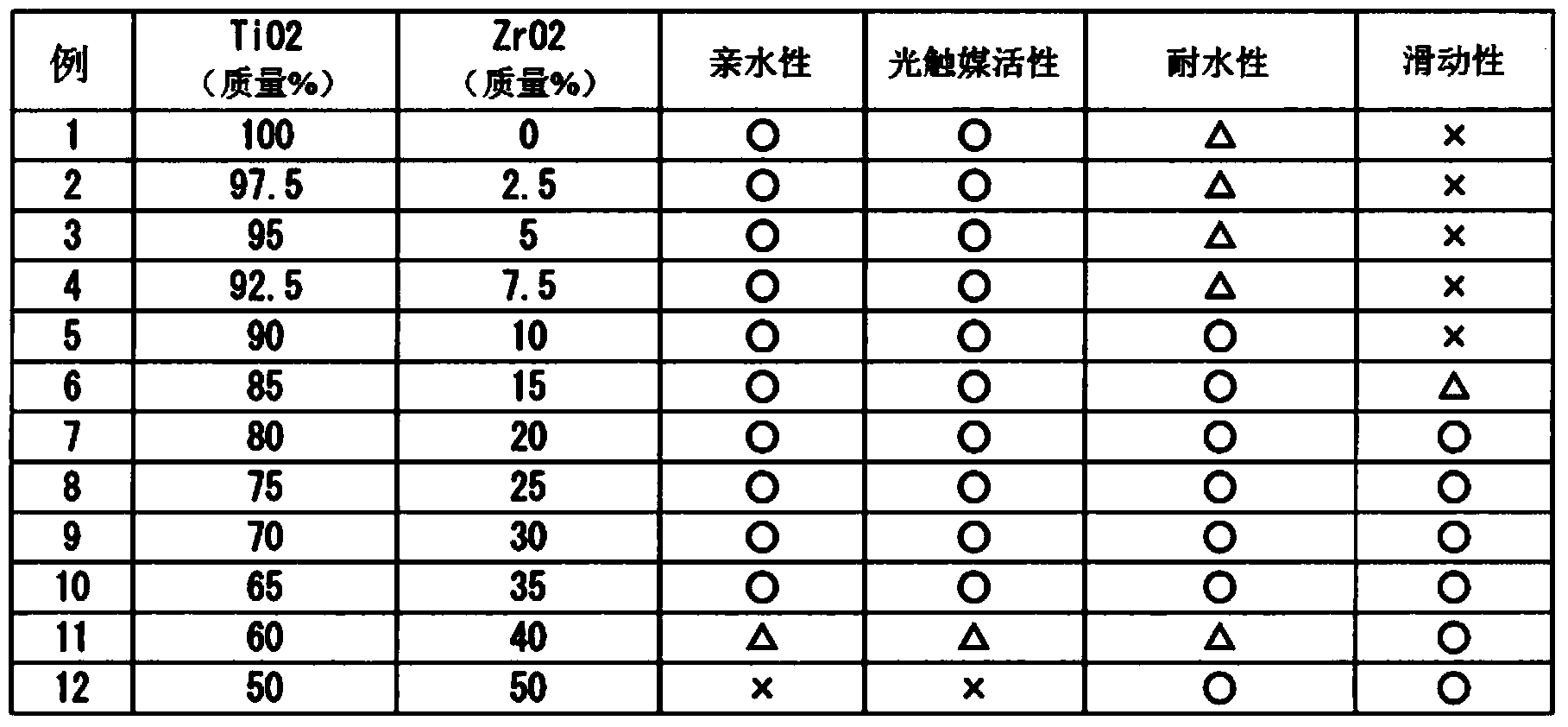

[0039] Preparation of coating solution for forming photocatalyst layer

[0040] Titanium alkoxide (titanium diisopropoxide bis(acetylacetonate), NDH-510C, manufactured by Nippon Soda Co., Ltd.) and zirconium alkoxide (tributoxyzirconium monoacetylacetonate, Orgatix ZC -540, manufactured by Japan Matsumoto Fine Chemical Co., Ltd.) can be mixed so that the weight ratio of the solid content after firing can be in the ratio shown in the following table. Next, this mixture was diluted with a mixed solvent of 2-propanol (80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com