Composite support material for semi-permeable membrane and manufacturing method thereof

A technology of composite support and semi-permeable membrane, which is applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc. Effects of foam collapse, penetration suppression, and uniformity assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

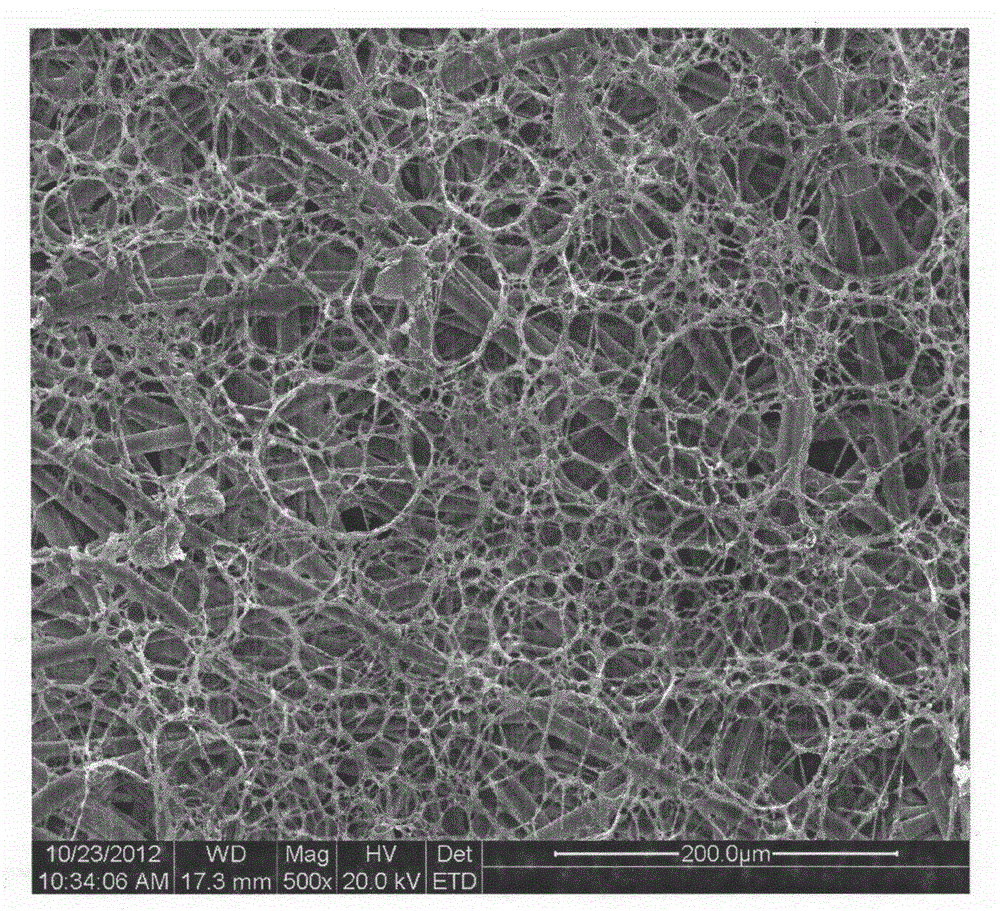

Image

Examples

Embodiment 1

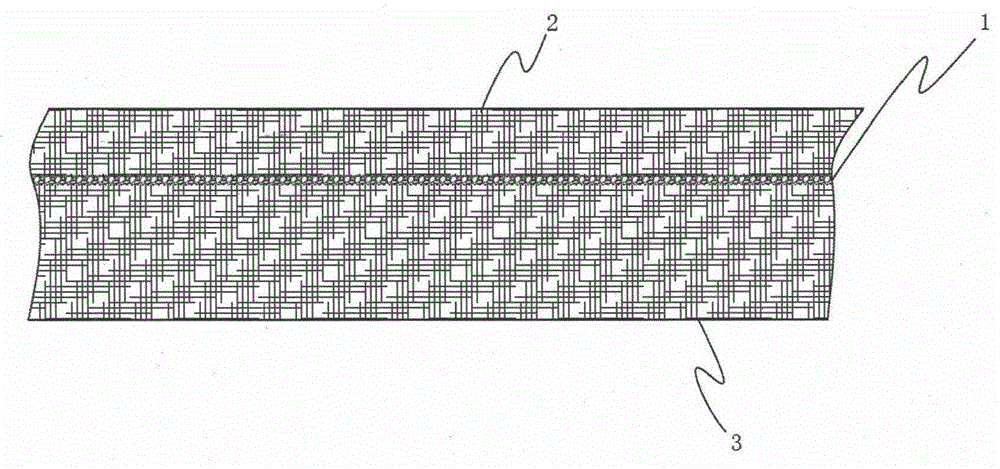

[0030]A composite support material for a semipermeable membrane, consisting of one layer of semipermeable membrane coating layer, one layer of foam adhesive coating layer and one layer of semipermeable membrane non-coating layer, the foam adhesive coating layer is set Between the coated layer of the semipermeable membrane and the uncoated layer of the semipermeable membrane. Such as figure 2 As shown, the thickness ratio of the foam adhesive coating layer 1, the semipermeable membrane coating layer 2 and the semipermeable membrane non-coating layer 3 is 1:6:12. Its manufacturing method is:

[0031] As the X surface layer, the main synthetic fiber (polyester fiber, fiber diameter 8.5 μm, fiber length 5 mm) and binder synthetic fiber (polyester fiber, fiber diameter 11 μm, fiber length 3 mm) are mixed in a ratio of 70:30 Mix and disperse in water, and use a cylinder paper machine to wet paper to form wet paper, then use a drying cylinder with a surface temperature of 130°C to...

Embodiment 2

[0038] A composite support material for a semipermeable membrane, consisting of one layer of semipermeable membrane coating layer, one layer of foam adhesive coating layer and one layer of semipermeable membrane non-coating layer, the foam adhesive coating layer is set Between the coated layer of the semipermeable membrane and the uncoated layer of the semipermeable membrane. Such as figure 2 As shown, the thickness ratio of the foam adhesive coating layer 1, the semipermeable membrane coating layer 2 and the semipermeable membrane non-coating layer 3 is 1:11:11. Its manufacturing method is:

[0039] As the X surface layer, the main synthetic fiber (polyester fiber, fiber diameter 8.5 μm, fiber length 5 mm) and binder synthetic fiber (polyester fiber, fiber diameter 11 μm, fiber length 3 mm) are mixed in a ratio of 70:30 Mix and disperse in water, use inclined wire paper machine to wet paper to form wet paper, and use a drying cylinder with a surface temperature of 130°C to...

Embodiment 3

[0046] A composite support material for a semipermeable membrane, consisting of one layer of semipermeable membrane coating layer, one layer of foam adhesive coating layer and one layer of semipermeable membrane non-coating layer, the foam adhesive coating layer is set Between the coated layer of the semipermeable membrane and the uncoated layer of the semipermeable membrane. Such as figure 2 As shown, the thickness ratio of the foam adhesive coating layer 1, the semipermeable membrane coating layer 2 and the semipermeable membrane non-coating layer 3 is 1:12:6. Its manufacturing method is:

[0047] As the X surface layer, the main synthetic fiber (polyester fiber, fiber diameter 8.5 μm, fiber length 5 mm) and binder synthetic fiber (polyester fiber, fiber diameter 11 μm, fiber length 3 mm) are mixed in a ratio of 70:30 Mix and disperse in water, use inclined wire paper machine to wet paper to form wet paper, and use a drying cylinder with a surface temperature of 130°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com