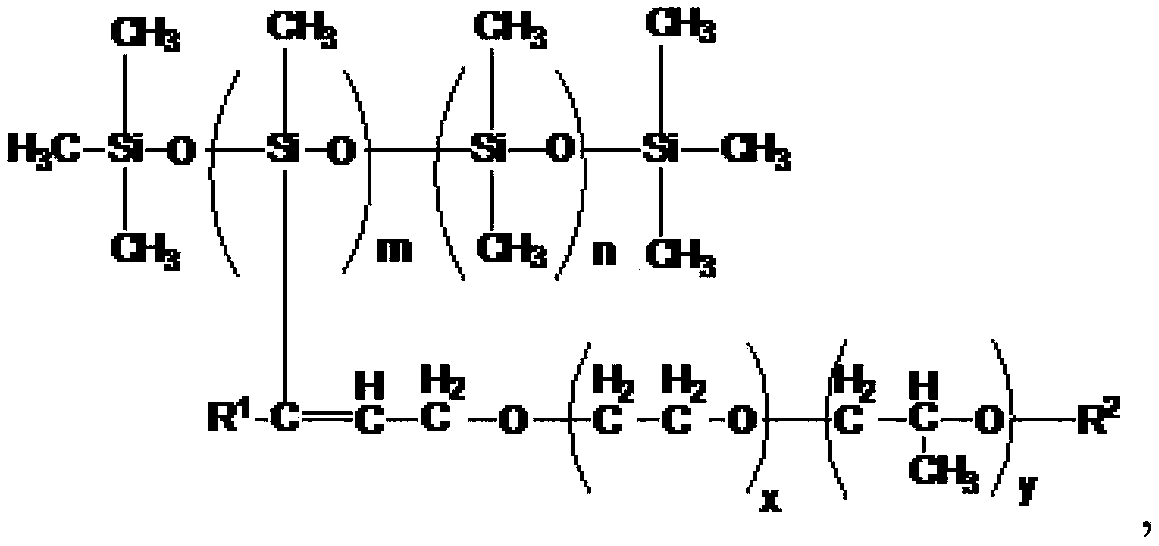

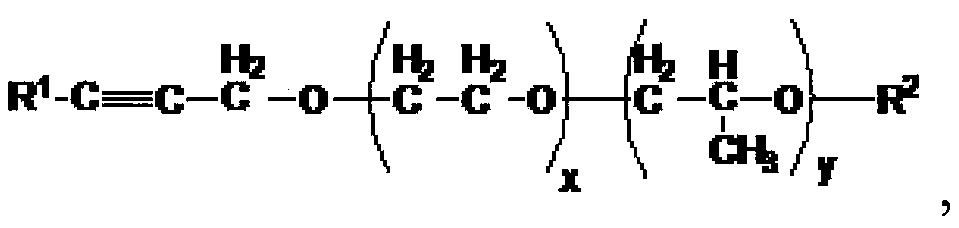

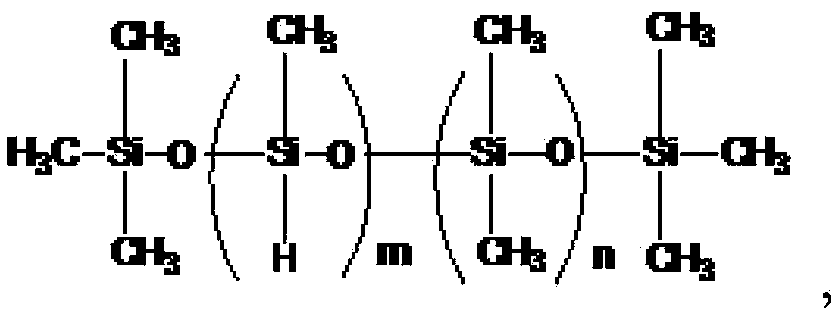

Acetylene bond-containing polyether modified polysiloxane surfactant and synthetic method thereof

A surfactant, acetylenic bond polyether technology, applied in chemical instruments and methods, silicon organic compounds, transportation and packaging, etc., can solve the problems of high risk, lengthy reaction process, hydrogen embrittlement, etc., and achieve non-crosslinking polymerization. By-products, high product purity, easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 14.5kg of propargyl alcohol polyether and 1.8g of chloroplatinic acid catalyst into the reaction kettle, slowly heat up to 80°C for direct activation, then add 22.3kg of hydrogen-containing polysiloxane, control the temperature at 80-100°C, and react for 10 After one hour, after the reaction mixture becomes clear and transparent, continue to keep warm for a certain period of time, then cool down and discharge, and filter to obtain the product. The lowest surface tension of its 0.5% aqueous solution measured by a surface tensiometer is 20.2mN / m, and the contact angle on paraffin is 5°.

Embodiment 2

[0031] In the reaction kettle, add 13.5kg of butynediol monoethoxy ether and 1.5g of chloroplatinic acid catalyst, slowly raise the temperature to 100°C for activation for 1 hour, then add 18.6kg of hydrogen-containing polysiloxane, and control the temperature at 100°C ~120°C, after 15 hours of reaction, the reaction mixture becomes clear and transparent, continue to keep warm for a certain period of time, then cool down and discharge, and filter to obtain the product. The minimum surface tension of its 0.5% aqueous solution measured by a surface tensiometer is 20.0mN / m, and the contact angle on paraffin is 0°.

Embodiment 3

[0033] In the reaction kettle, add 19.1kg of butynediol diethoxy ether and 1.4g of rhodium chloride catalyst, slowly heat up to 120°C for activation for 2 hours, then add 25.7kg of hydrogen-containing polysiloxane, and control the temperature at 120°C ~140°C, after 6 hours of reaction, the reaction mixture becomes clear and transparent, continue to keep warm for a certain period of time, then cool down and discharge, and filter to obtain the product. The minimum surface tension of its 0.5% aqueous solution measured by a surface tensiometer is 21.5mN / m, and the contact angle on paraffin is 10°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Minimum surface tension | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com