A visible light-responsive tb/bivo 4 Catalyst and its preparation method and application

A catalyst and visible light technology, applied in the field of visible light responsive Tb/BiVO4 catalyst and its preparation, can solve problems such as low catalytic efficiency, and achieve the effects of simple process flow, mild reaction conditions and no hysteresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

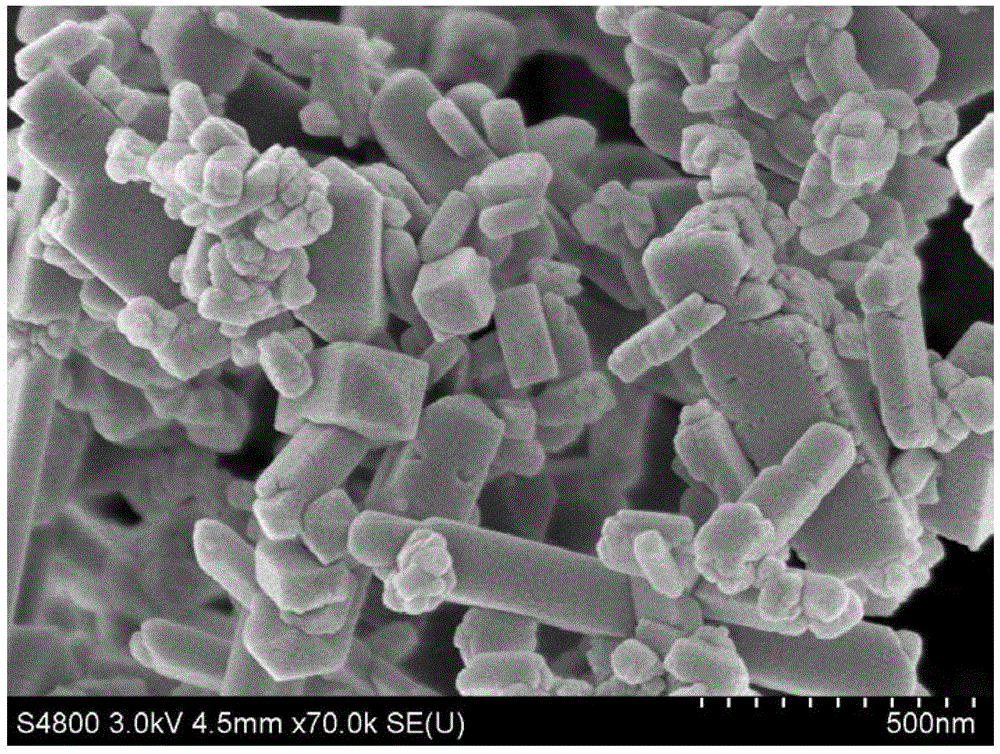

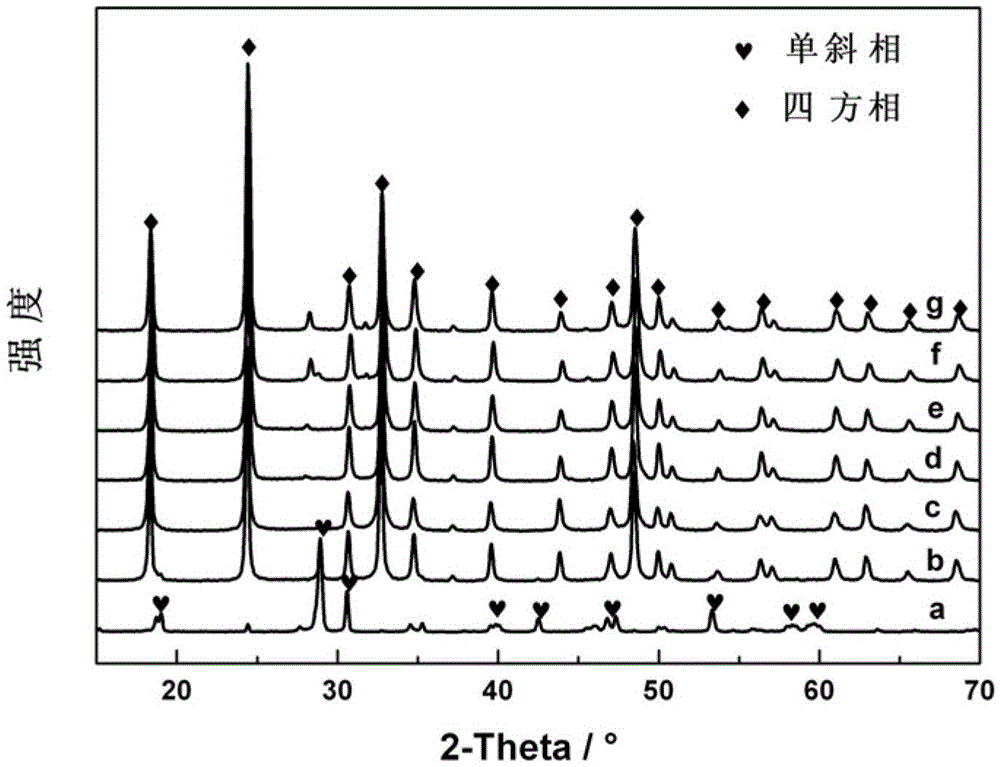

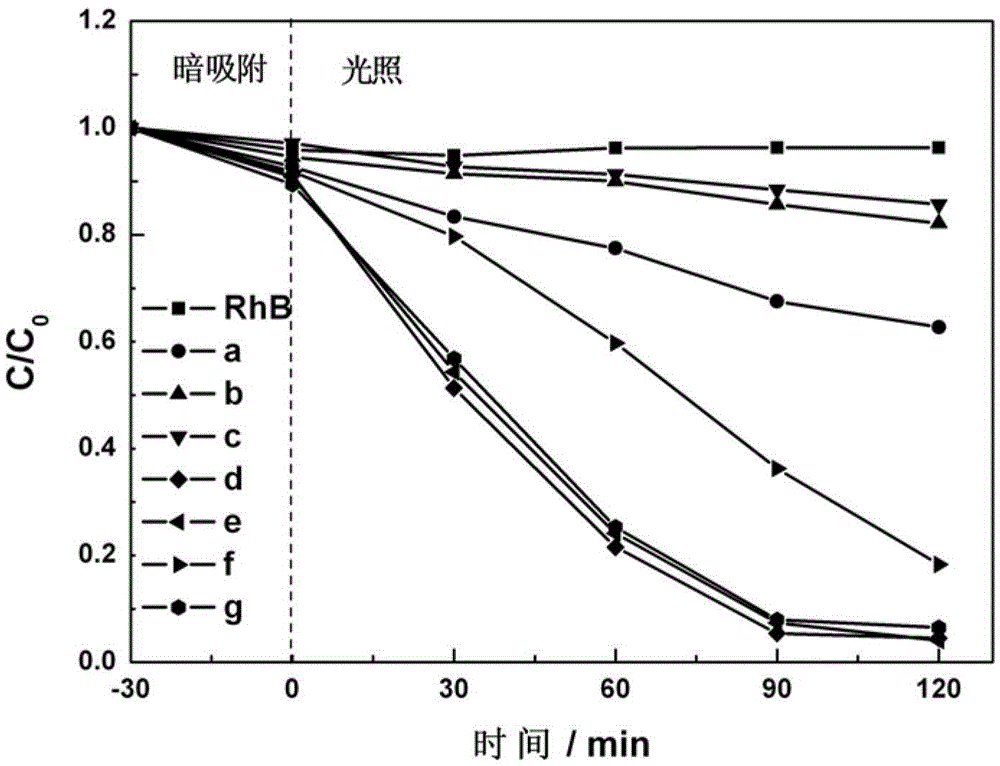

[0031] A Visible Light Responsive Tb / BiVO 4 Catalyst whose main component is BiVO 4 , is a tetragonal zircon phase structure, and BiVO 4 The lattice contains Tb 3+ , wherein the molar ratio of Tb element to Bi element is 2.04:100.

[0032] A Visible Light Responsive Tb / BiVO 4 The preparation method of catalyst comprises the following steps:

[0033] Step 1: Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water and stirred on a magnetic stirrer for 20 min to obtain Bi(NO 3 ) 3 ·5H 2 Bismuth salt solution with O concentration of 0.4mol / L; NH 4 VO3 Dissolve in deionized water at 100°C, heat and stir at 100°C for 20min to obtain NH 4 VO 3 Concentration is the vanadium salt solution of 0.4mol / L;

[0034] Step 2: slowly drop the vanadium salt solution into the bismuth salt solution according to the molar ratio of Bi and V of 1:1, and stir on a magnetic stirrer for 15 minutes to obtain a mixed solution;

[0035] Step 3: Add dropwise NaOH solution with a concentration of ...

Embodiment 2

[0040] A Visible Light Responsive Tb / BiVO 4 Catalyst whose main component is BiVO 4 , is a tetragonal zircon phase structure, and BiVO 4 The lattice contains Tb 3+ , wherein the molar ratio of Tb element to Bi element is 4.17:100.

[0041] A Visible Light Responsive Tb / BiVO 4 The preparation method of catalyst comprises the following steps:

[0042] Step 1: Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water and stirred on a magnetic stirrer for 20 min to obtain Bi(NO 3 ) 3 ·5H 2 Bismuth salt solution with O concentration of 0.4mol / L; NH 4 VO 3 Dissolve in deionized water at 100°C, heat and stir at 90°C for 20min to obtain NH 4 VO 3 Concentration is the vanadium salt solution of 0.4mol / L;

[0043] Step 2: slowly drop the vanadium salt solution into the bismuth salt solution according to the molar ratio of Bi and V of 1:1, and stir on a magnetic stirrer for 15 minutes to obtain a mixed solution;

[0044] Step 3: Add dropwise NaOH solution with a concentration of...

Embodiment 3

[0049] A Visible Light Responsive Tb / BiVO 4 Catalyst whose main component is BiVO 4 , is a tetragonal zircon phase structure, and BiVO 4 The lattice contains Tb 3+ , wherein the molar ratio of Tb element to Bi element is 6.38:100.

[0050] A Visible Light Responsive Tb / BiVO 4 The preparation method of catalyst comprises the following steps:

[0051] Step 1: Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water and stirred on a magnetic stirrer for 20 min to obtain Bi(NO 3 ) 3 ·5H 2 Bismuth salt solution with O concentration of 0.4mol / L; NH 4 VO 3 Dissolve in deionized water at 100°C, heat and stir at 95°C for 20min to obtain NH 4 VO 3 Concentration is the vanadium salt solution of 0.4mol / L;

[0052] Step 2: slowly drop the vanadium salt solution into the bismuth salt solution according to the molar ratio of Bi and V of 1:1, and stir on a magnetic stirrer for 15 minutes to obtain a mixed solution;

[0053] Step 3: Add dropwise NaOH solution with a concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com