Purification process for o-phenylenediamine

A technology of o-phenylenediamine and process, which is applied in the field of purification process of o-phenylenediamine, can solve the problems that the content and color number are difficult to meet high-quality requirements, and achieve the effects of reduced energy consumption, stable and reliable operation, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

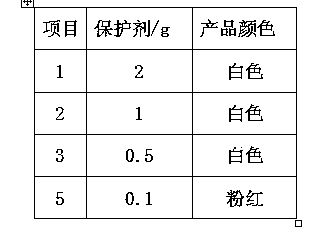

[0017] Raw material: crude o-phenylenediamine, o-phenylenediamine content of 90%, tan crystalline appearance; more than 80% of protective agent, it is an industrial product.

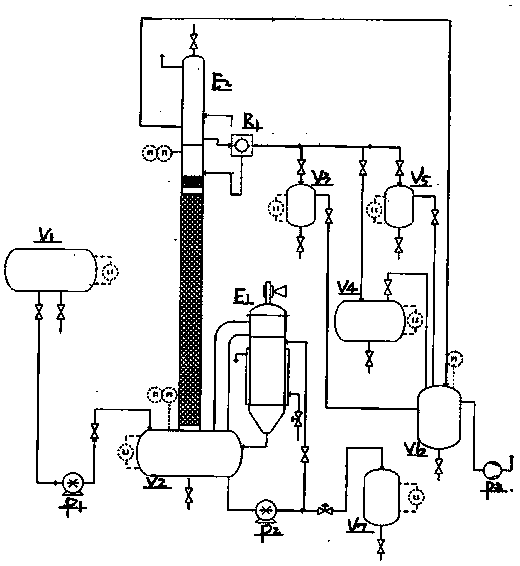

[0018] Pilot equipment:

[0019] 1) Rectification equipment: 3600L distillation kettle, made of 304 stainless steel; Φ600×195000mm rectification tower, packing height of 9000mm, made of 304 stainless steel;

[0020] 2) Crystallization equipment: vacuum or nitrogen protection flake machine.

[0021] The purification process of o-phenylenediamine is as follows:

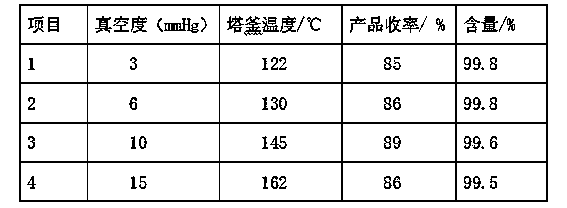

[0022] 4 tons of crude o-phenylenediamine with a content of 90% pre-dissolved in the storage tank V1 are transported to the distillation column still at 120±2°C through the pump P1, and the ingredients are circulated in the thin-film evaporator E1 by the circulating pump P2 for heating. , produce gas, rise to the tower for exchange and separation through packing, the gas phase is cooled by the condenser E2 at the top of the tower to form a liqui...

Embodiment 2

[0026] The degree of vacuum in this example is 6 mmHg, the temperature of the tower still is 130° C., the protective agent is 1 g, and the rest are the same as in Example 1.

Embodiment 3

[0028] The vacuum degree in this embodiment is 10mmHg, the temperature of the tower still is 145 DEG C, and the protective agent is 0.5g, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com