Post-processing method of fusible polytetrafluoroethylene

A polytetrafluoroethylene and tetrafluoroethylene technology, which is applied in the field of preparation of fusible polytetrafluoroethylene granules, can solve the problems affecting mechanical properties and stability, deepening color, and purity of fusible polytetrafluoroethylene products. drop etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the preparation method of the fusible polytetrafluoroethylene granulation material of the present invention, firstly, the fusible polytetrafluoroethylene slurry with a certain solid content is added into a kettle filled with a specific solvent, and left to stand or stirred at a slow speed for a certain period of time Finally, heat up and keep warm under stirring, and at the same time, condense and recover the evaporated gaseous solvent through a heat exchanger, and finally add inorganic salt or alkali to the kettle to further heat up, and keep it for a period of time, then cool down, filter, wash, and dry The fusible polytetrafluoroethylene pellets were obtained.

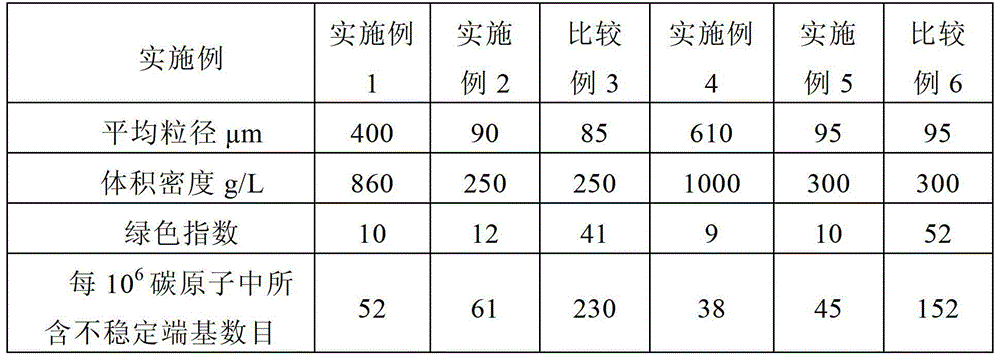

[0032] After being processed by the method of the present invention, the obtained meltable polytetrafluoroethylene pellets have relatively large bulk density, uniform and controllable particle size, good thermal stability, and can be directly used for extrusion to obtain translucent and glossy pellets. adv...

Embodiment 1

[0048] 1. obtain fusible polytetrafluoroethylene slurry by the method of U.S. Patent 3,635,926 embodiment 1

[0049] Add 6 g of ammonium persulfate and 10 g of ammonium perfluorooctanoate to a 6.2 liter stainless steel reactor with stirring device. It was then evacuated and purged three times with tetrafluoroethylene, after which 3.44 liters of dedistilled water and 75 g of perfluoropropyl vinyl ether were sucked in. Start the stirring device and heat to 70°C, add tetrafluoroethylene monomer while stirring at 125 rpm and maintain the pressure at 250 psig. After 18 minutes the reaction was terminated by evacuation of unreacted monomer. Take out the fusible polytetrafluoroethylene slurry, its solid content is 15wt%.

[0050] 2. Post-processing

[0051] Take 1 kg of the meltable polytetrafluoroethylene slurry prepared above and put it into a 10-liter stainless steel reactor equipped with a heat exchanger, and add 5 liters of trifluorotrichloroethane and methanol at a ratio of ...

Embodiment 2

[0054] 1. obtain fusible polytetrafluoroethylene slurry by the method of U.S. Patent 3,635,926 embodiment 1

[0055] Add 6 g of ammonium persulfate and 10 g of ammonium perfluorooctanoate to a 6.2 liter stainless steel reactor with stirring device. It was then evacuated and purged three times with tetrafluoroethylene, after which 3.44 liters of dedistilled water and 75 g of perfluoropropyl vinyl ether were sucked in. Start the stirring device and heat to 70°C, add tetrafluoroethylene monomer while stirring at 125 rpm and maintain the pressure at 250 psig. After 18 minutes the reaction was terminated by evacuation of unreacted monomer. Take out the fusible polytetrafluoroethylene slurry, its solid content is 15wt%.

[0056] 2. Post-processing

[0057] Take 1 kg of the fusible polytetrafluoroethylene slurry prepared by the above method and put it into a 10 liter capacity coagulation bucket, and add 5 liters of deionized water therein. Turn on the agitation switch of the coag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com