A slow-release food anti-oxidation packaging film and preparation method thereof

An anti-oxidation and packaging film technology, which is applied in the field of food packaging materials, can solve the problems of incomplete removal of oxygen inside the packaging, low antioxidant retention rate, and difficult anti-oxidation protection, so as to ensure reliability and good effectiveness, and promote Electron transfer, strong antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation steps of the packaging film of this example (without the addition of slow-release agent diatomaceous earth) are as follows:

[0032] (1) Weigh quercetin (product of Sinopharm Group Chemical Reagent Co., Ltd.) 1.5g, HDPE masterbatch (DGDA6098, product of Qilu Petrochemical) 100g, EVA masterbatch (14-2, product of Beijing Organic Chemical Factory) 100g, first Mix the two masterbatches evenly, set the temperature of the front roller of the plasticizing machine to 140°C, and the temperature of the rear roller to 130°C, place the mixed masterbatch in the double-roller plasticizing machine, and smelt for 5 minutes until the plasticization is uniform and good;

[0033] (2) Add quercetin evenly to the well-plasticized masterbatch in step (1), and smelt for 6 minutes until the quercetin is evenly mixed in the masterbatch;

[0034] (3) After the blended flakes of HDPE, EVA and quercetin are rolled well, unroll the flakes, spread them on a flat plate in a sin...

Embodiment 2

[0038] The preparation steps of the packaging film of this example (without the addition of slow-release agent diatomaceous earth) are as follows:

[0039] (1) Weigh 1.5g of quercetin (same as above), 130g of HDPE masterbatch (same as above), 70g of EVA masterbatch (same as above), first mix the two masterbatches evenly, set the temperature of the front roller of the plastic refining machine to 142°C, The temperature of the rear roller is 132°C, and the mixed masterbatch is placed in a double-roller plastic refining machine, and the plastic is refined for 6 minutes until the plasticization is uniform and good;

[0040] (2) Add quercetin evenly to the well-plasticized masterbatch in step (1), and smelt for 7 minutes until the quercetin is evenly mixed in the masterbatch;

[0041] (3) After the blended flakes of HDPE, EVA and quercetin are rolled well, unroll the flakes, spread them on a flat plate in a single layer, and cut them into 2cm×2cm squares after cooling for 15 m...

Embodiment 3

[0045] Example packaging film (without adding slow-release agent diatomaceous earth) preparation steps are as follows:

[0046] (1) Weigh 1.5g of quercetin (same as above), 160g of HDPE masterbatch (same as above), and 40g of EVA masterbatch (same as above). The temperature of the rear roller is 135°C, and the mixed masterbatch is placed in a double-roller plastic refining machine, and the plastic is refined for 8 minutes until the plasticization is uniform and good;

[0047] (2) Add quercetin evenly to the well-plasticized masterbatch in step (1), and knead for 8 minutes until the quercetin is evenly mixed in the masterbatch;

[0048] (3) After the blended flakes of HDPE, EVA and quercetin are rolled well, unroll the flakes, spread them on a flat plate in a single layer, and cut them into 2cm×2cm squares after cooling for 20 minutes;

[0049] (4) Preheat the metal platen, weigh 6.2g of the thin slice obtained in step (3), place it between two metal platens, and pla...

PUM

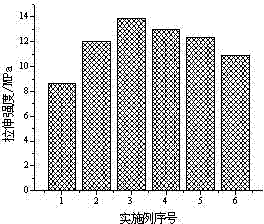

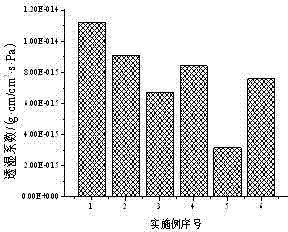

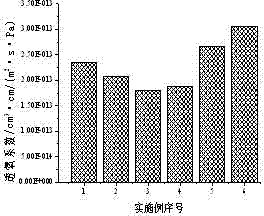

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Oxygen permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com