Conductive cross arm made of all-aluminum alloy profile

A technology of aluminum alloy profiles and conductive cross arms, which is applied in the field of metallurgical industrial equipment, can solve the problems of high pressure requirements of electrode lifting cylinders and hydraulic circuits, reducing the sensitivity of electrode lifting mechanisms, and cumbersome processing processes, and achieves great promotion value and application prospects. , Improve the sensitivity and response speed, the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in combination with specific embodiments.

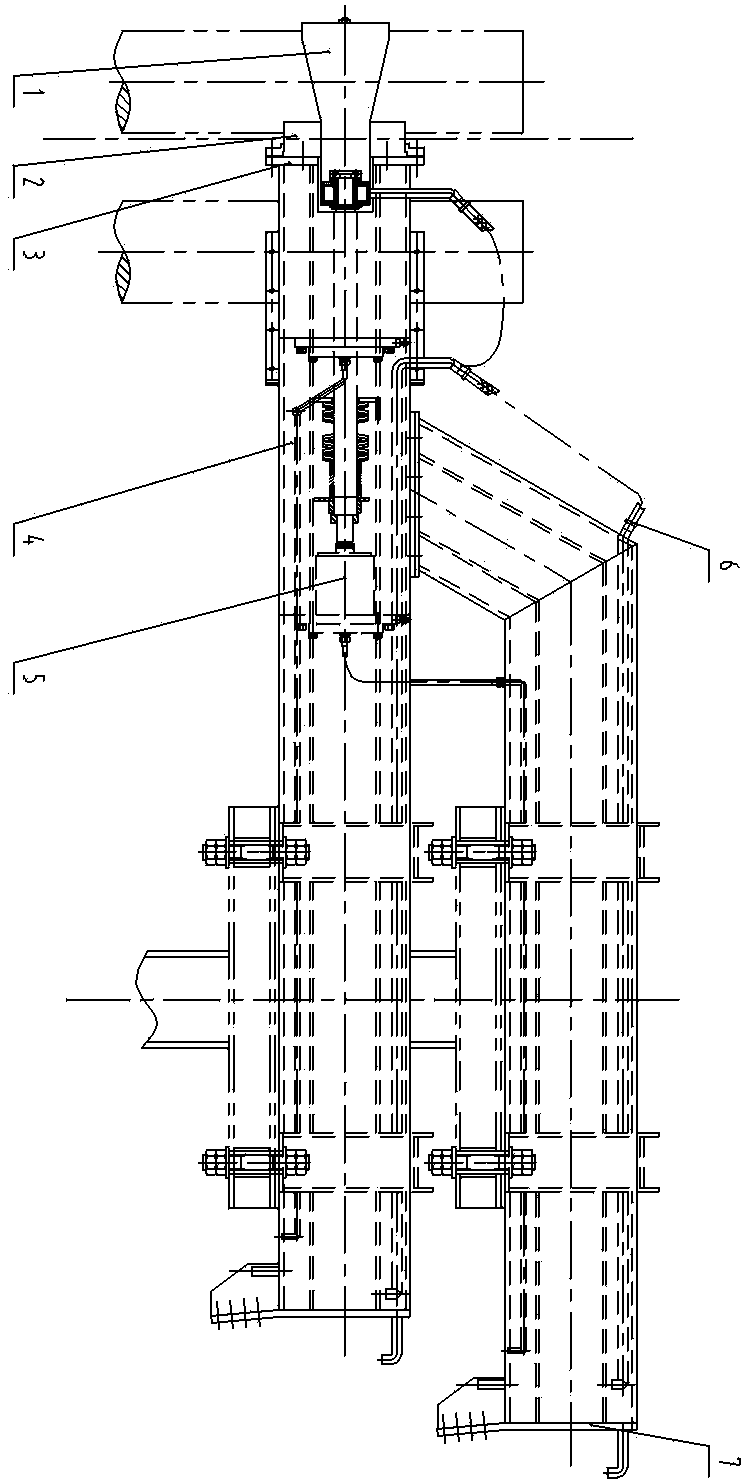

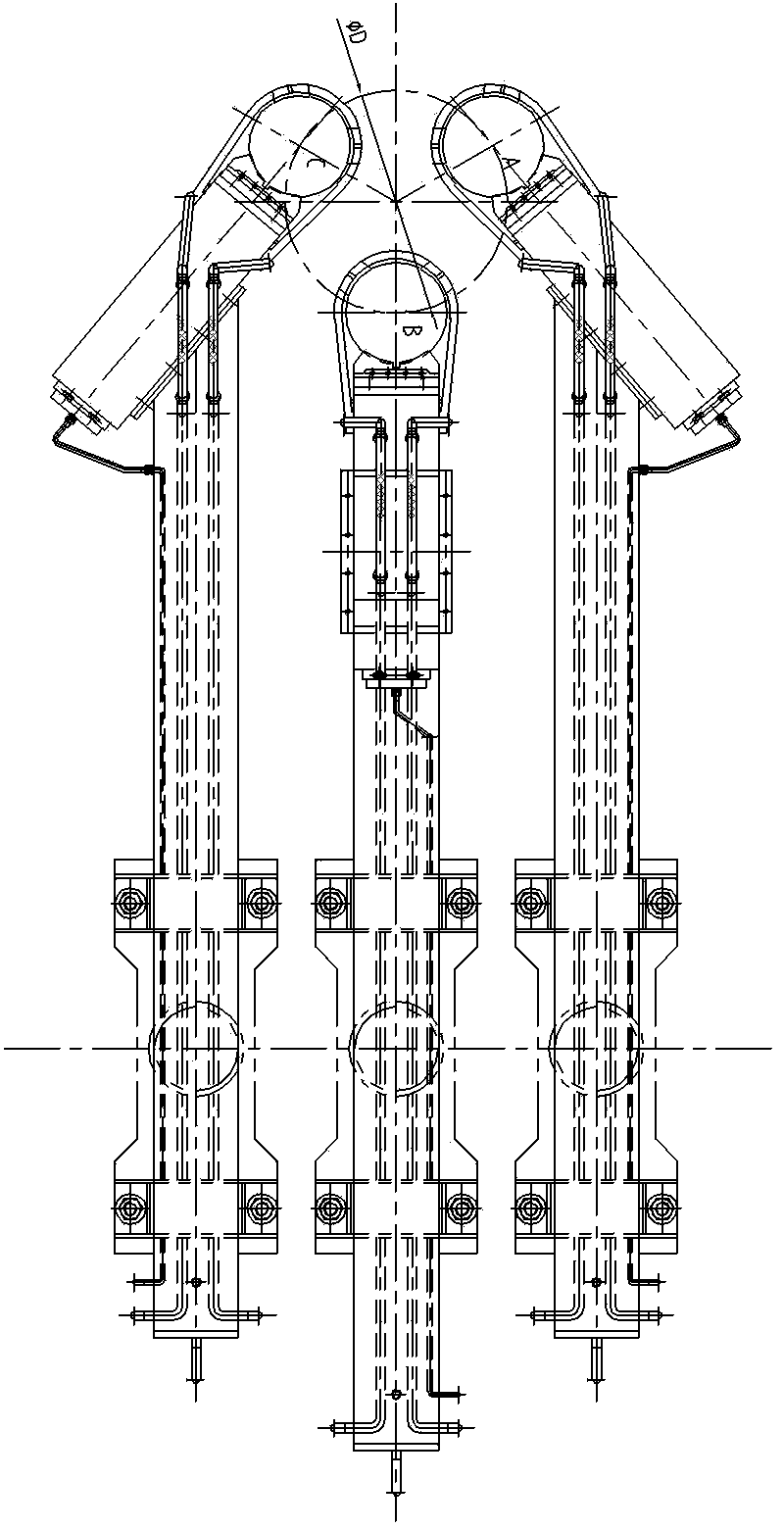

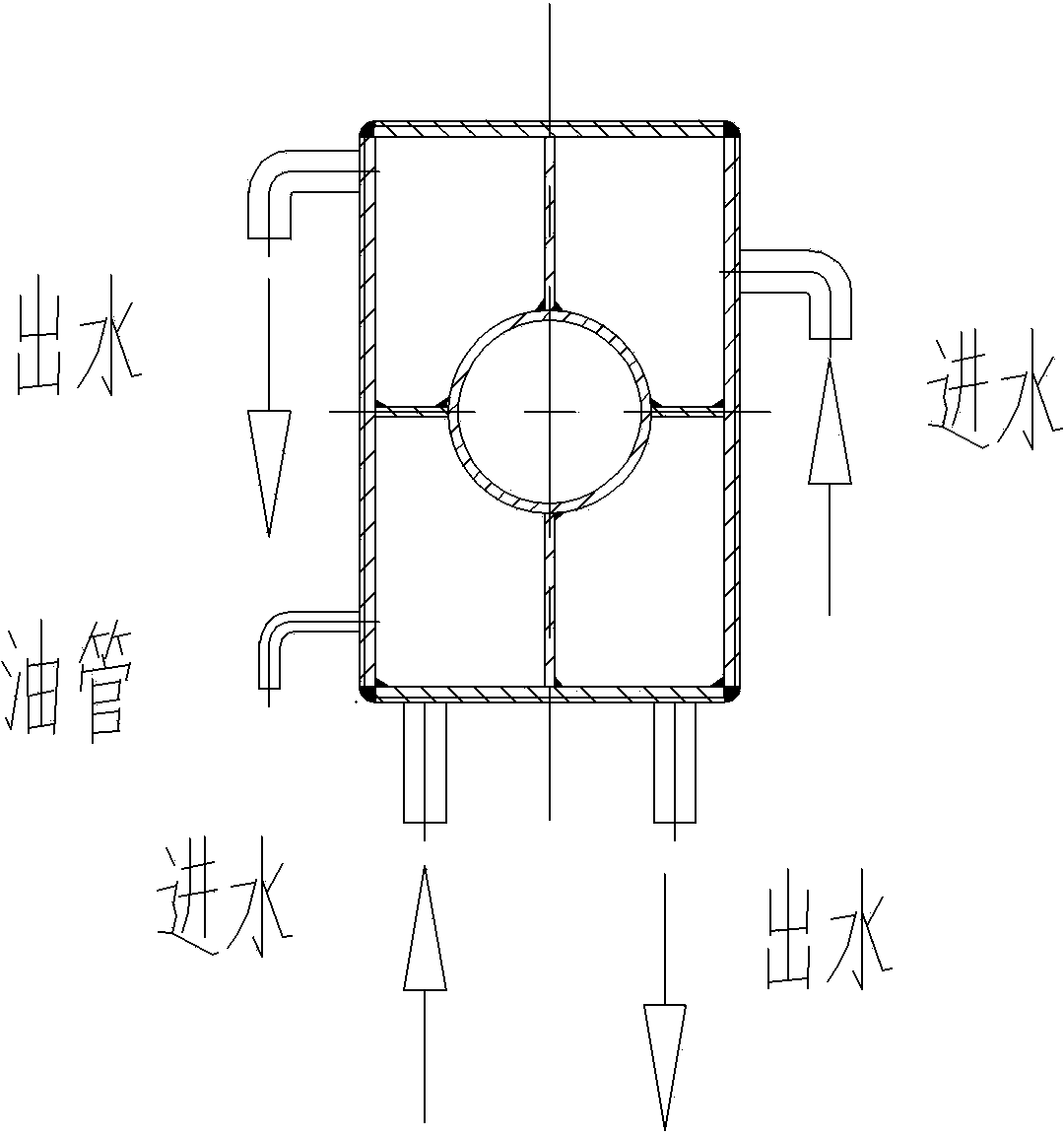

[0025] An all-aluminum alloy profile conductive cross arm involved in the present invention, the cross arm body 4 is also a rectangular cross-section, and the core tube, peripheral plates and middle ribs inside the cross arm body 4 are all of good electrical conductivity and high mechanical strength. High and corrosion-resistant aluminum alloy material, formed by hot extrusion, aging and oxidation, has a large conductive surface, no welding, high strength, corrosion resistance, no cumbersome processing process, short cycle time, and light weight. The flanges are welded at the 4 bends of the cross arm body and connected by bolts. There are upper and lower nozzles and sealing grooves on the flanges, and are equipped with high-temperature resistant sealing rings. see image 3 , the interior of the existing cross arm is a carbon steel / aluminum alloy seamless core tube, the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap