Tissue quantitative analysis method for TRIP steel

A quantitative analysis and organization technology, applied in material analysis using radiation diffraction, material analysis using measurement of secondary emissions, preparation of samples for testing, etc. The problem of high equipment requirements, to achieve the effect of small human interference factors, low operator requirements, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

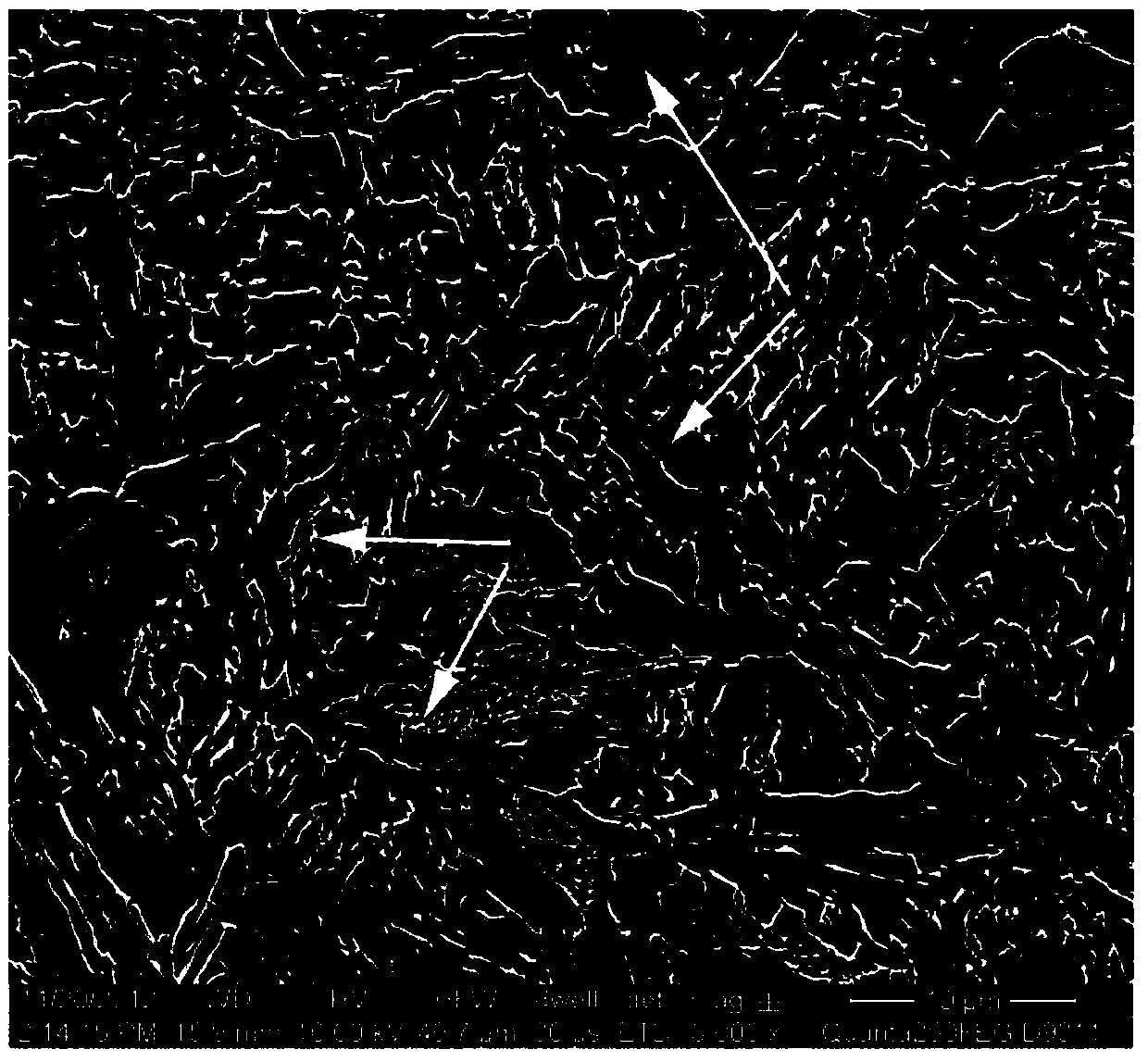

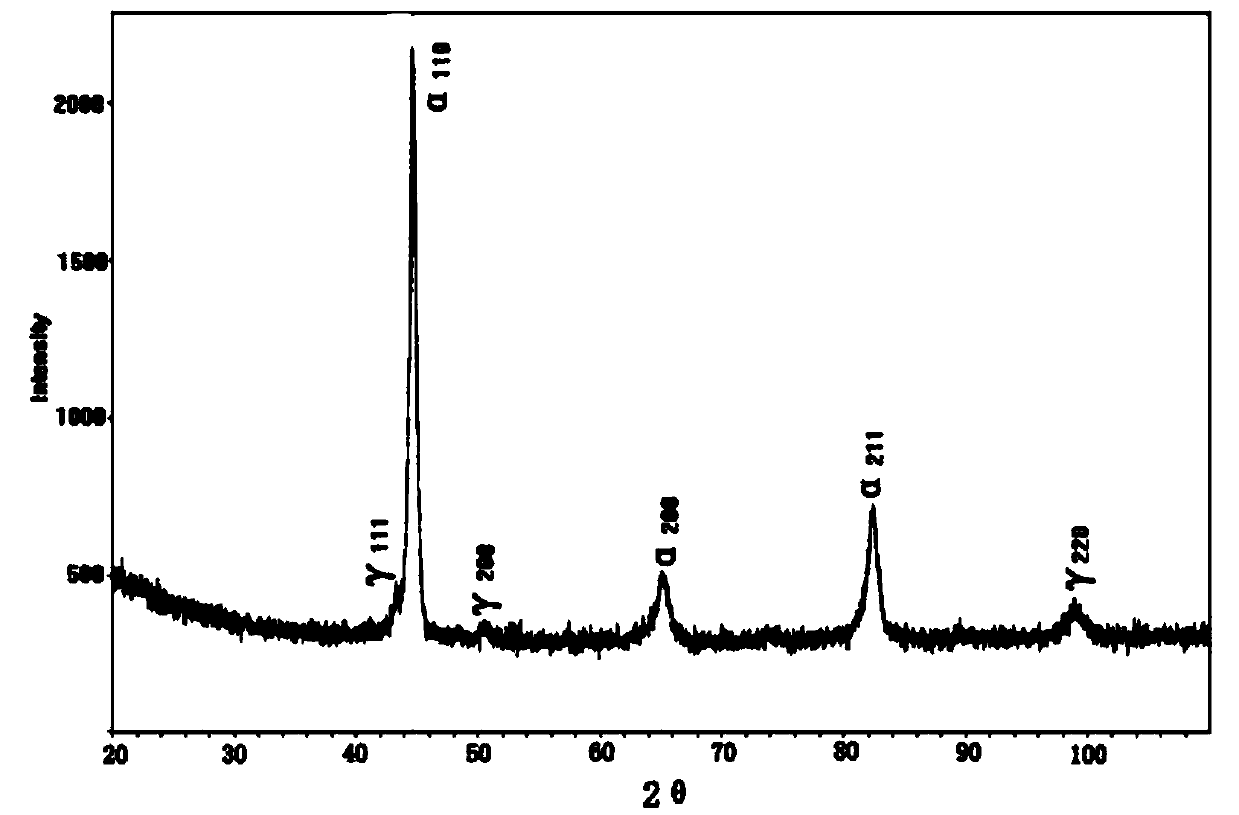

[0020] The chemical composition (mass fraction, %) of TRIP steel is: C0.31, Si1.86, Mn1.86, Nb0.035 and the rest is Fe. The experimental TRIP steel was kept at 1180°C for 1.5 hours, and was rolled into a 12mm plate by the two-roll reversing hot rolling unit of the National Iron and Steel Rolling Center of Beijing University of Science and Technology through the controlled rolling and controlled cooling process. After polishing, the sample was corroded by a 4% nitric acid alcohol solution in a weight ratio, and the microstructure was observed in a scanning electron microscope S-4300, and the software Image-Pro Plus6.0 was used to analyze and count the metal phase ratio of each phase; the XRD diffractometer was used to analyze the The experimental TRIP steel was tested by XRD, the experimental conditions were Cu Kα radiation, the wavelength was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com