Double three-phase permanent magnet motor vector control method based on proportional resonance regulator

A dual-three-phase permanent magnet and vector control technology, which is applied in vector control systems, motor generator control, electronic commutation motor control, etc., can solve problems such as limited control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

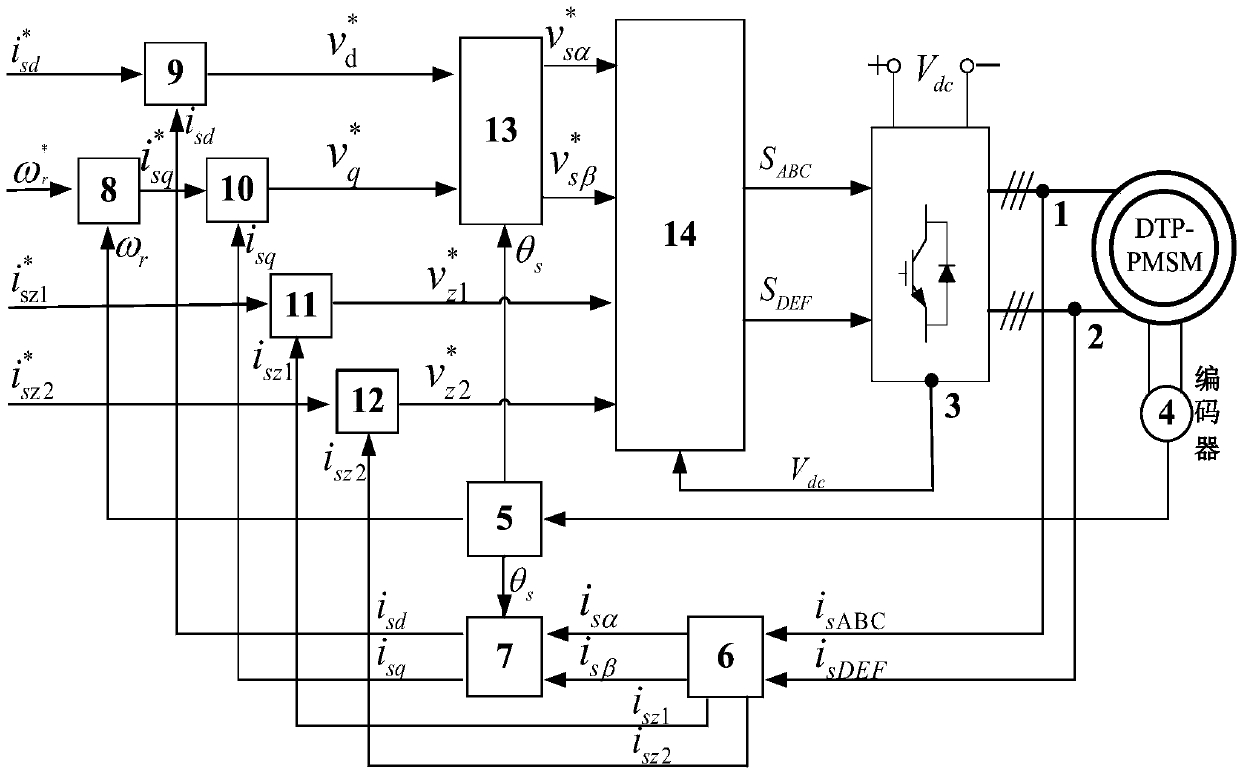

[0046] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

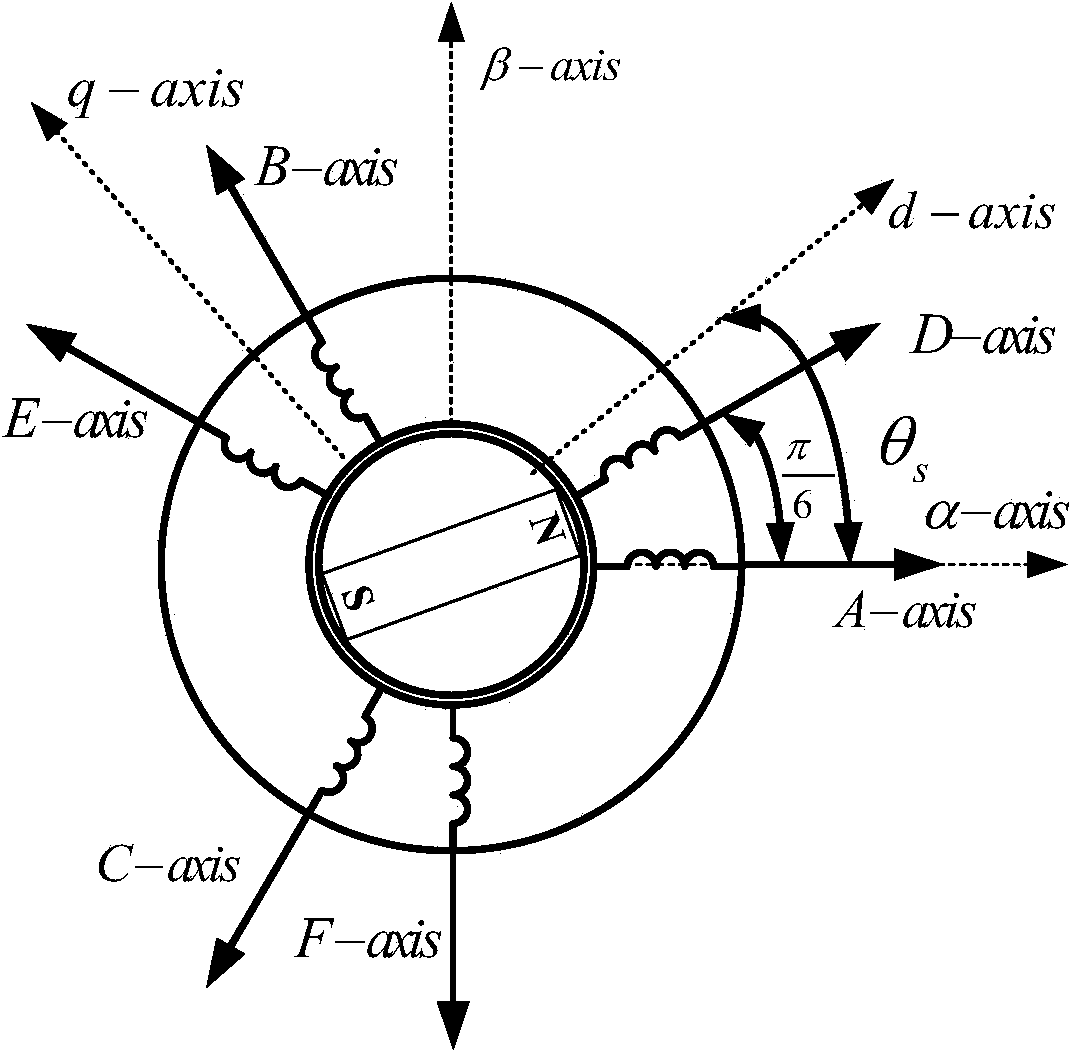

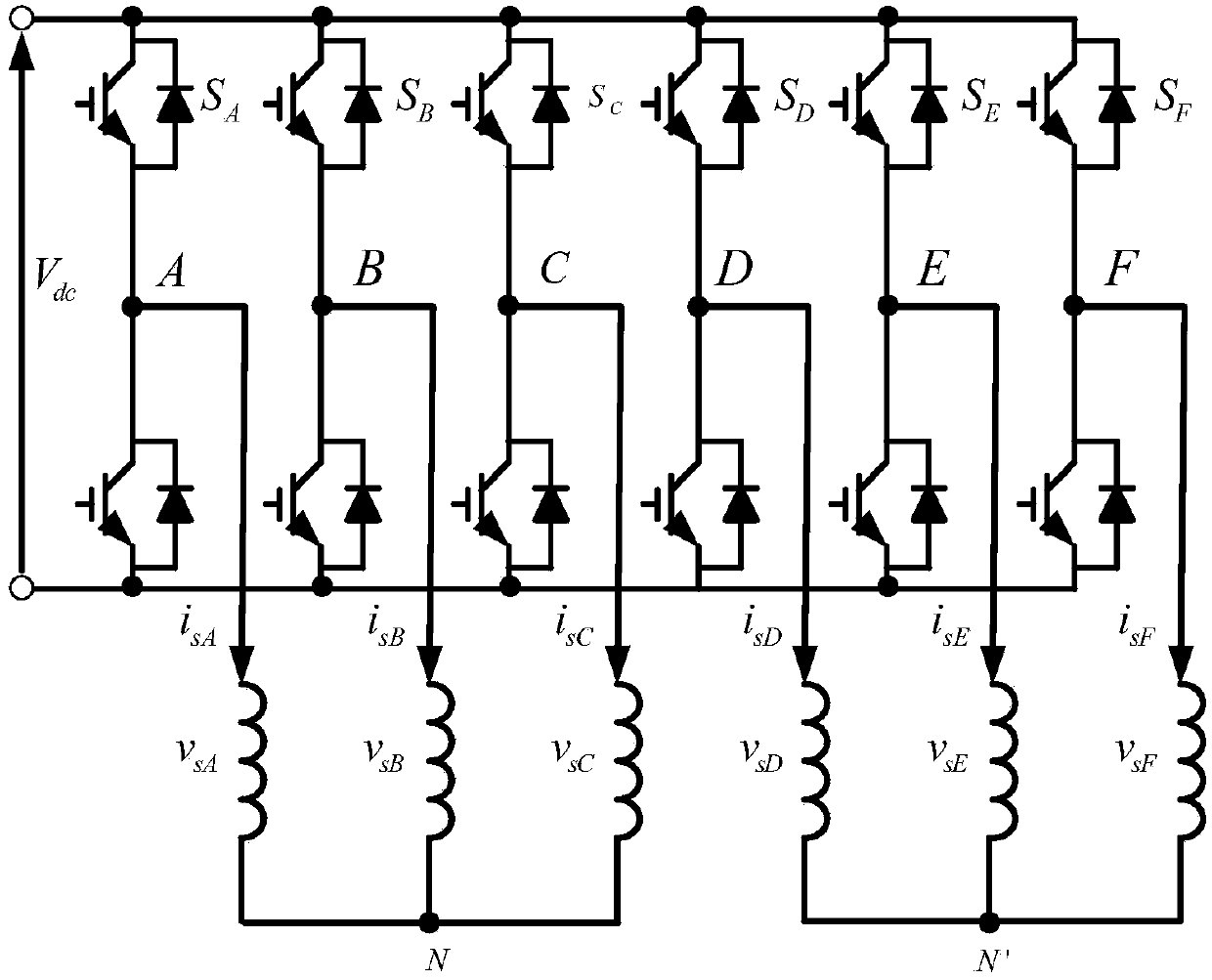

[0047] figure 1 It is a structural diagram of a dual three-phase permanent magnet synchronous motor. From the distribution of the stator winding, it can be seen that the stator winding is composed of two sets of conventional three-phase windings ABC and DEF, each set of windings is Y-connected, and the corresponding internal windings are 120° apart from each other in space, while the two sets of three-phase The angle between the corresponding phases of the windings is 30°. Therefore, in terms of hardware circuit design, the dual-three-phase permanent magnet synchronous motor is a six-phase system. In order to make the stator flux linkage and permanent magnet flux interaction generate constant electromagnetic torque, the phase winding current in each Y-shaped winding The phase difference is 120°, and the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com