Multistage hole ZSM-5/SiO2 catalyst, preparation method catalyst, and n-octane catalytic cracking method

A ZSM-5, catalytic cracking technology, applied in the petrochemical field, can solve the problem of high temperature in the cracking reaction of the tube furnace, and achieve the effect of excellent reaction performance and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a kind of hierarchical hole ZSM-5 / SiO based on small grain ZSM-5 2 Composite catalyst, it is prepared by the following steps:

[0047] At room temperature, weigh 27.38g of TPAOH and 19.82g of water, mix and stir, then add 0.38g of aluminum isopropoxide every half hour, then add 20.03g of TEOS after half an hour, and then stir the four substances together for 12h to obtain a mixed solution;

[0048] The mixed solution was subjected to open-open alcohol distillation treatment at 50°C for 6 hours, and the water lost due to evaporation was replenished during the alcohol distillation process;

[0049] Then by macroporous-mesoporous SiO 2 Carrier: silica sol=0.065:1 mass ratio Put the carrier into the mixed solution for 30 minutes, then pour the mixed solution and the substrate into the cleaned polytetrafluoroethylene hydrothermal synthesis kettle, and crystallize at 90°C 72h;

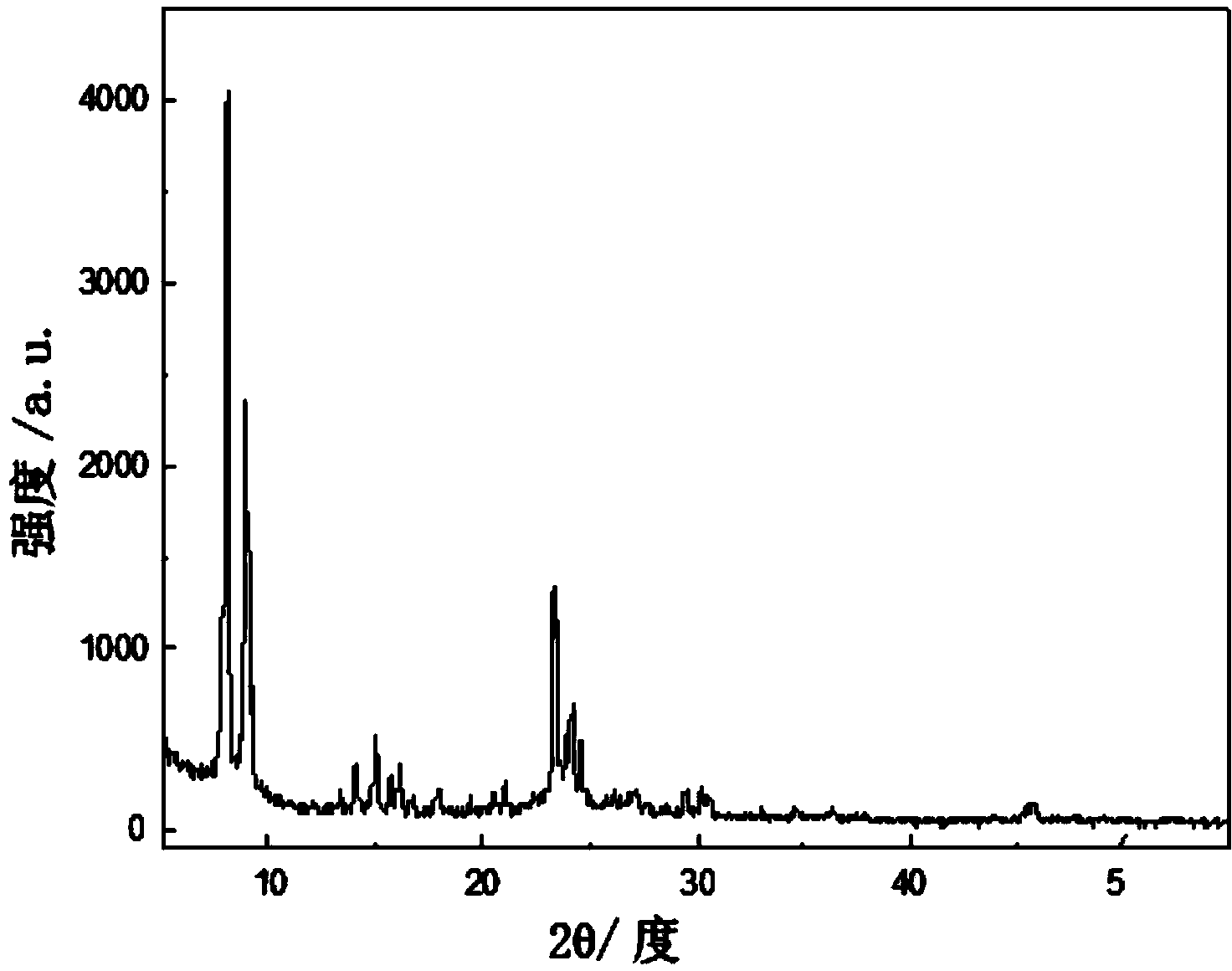

[0050] After the crystallization is completed, the synthesized solutio...

Embodiment 2

[0055] The sample crystallization time in Example 1 was changed to 96h, and other conditions were the same as in Example 1. The reaction results and yields of main products obtained are shown in Table 2.

[0056] The hierarchical porous ZSM-5 / SiO prepared in this example 2 The XRD patterns and SEM patterns of the composite catalyst are as follows Figure 2a and Figure 2b shown.

[0057] Table 2 Cracking reaction main product yield distribution

[0058]

Embodiment 3

[0060] The crystallization time of the sample in Example 1 was changed to 120 h, and other conditions were the same as in Example 1. The reaction results and yields of main products obtained are shown in Table 3.

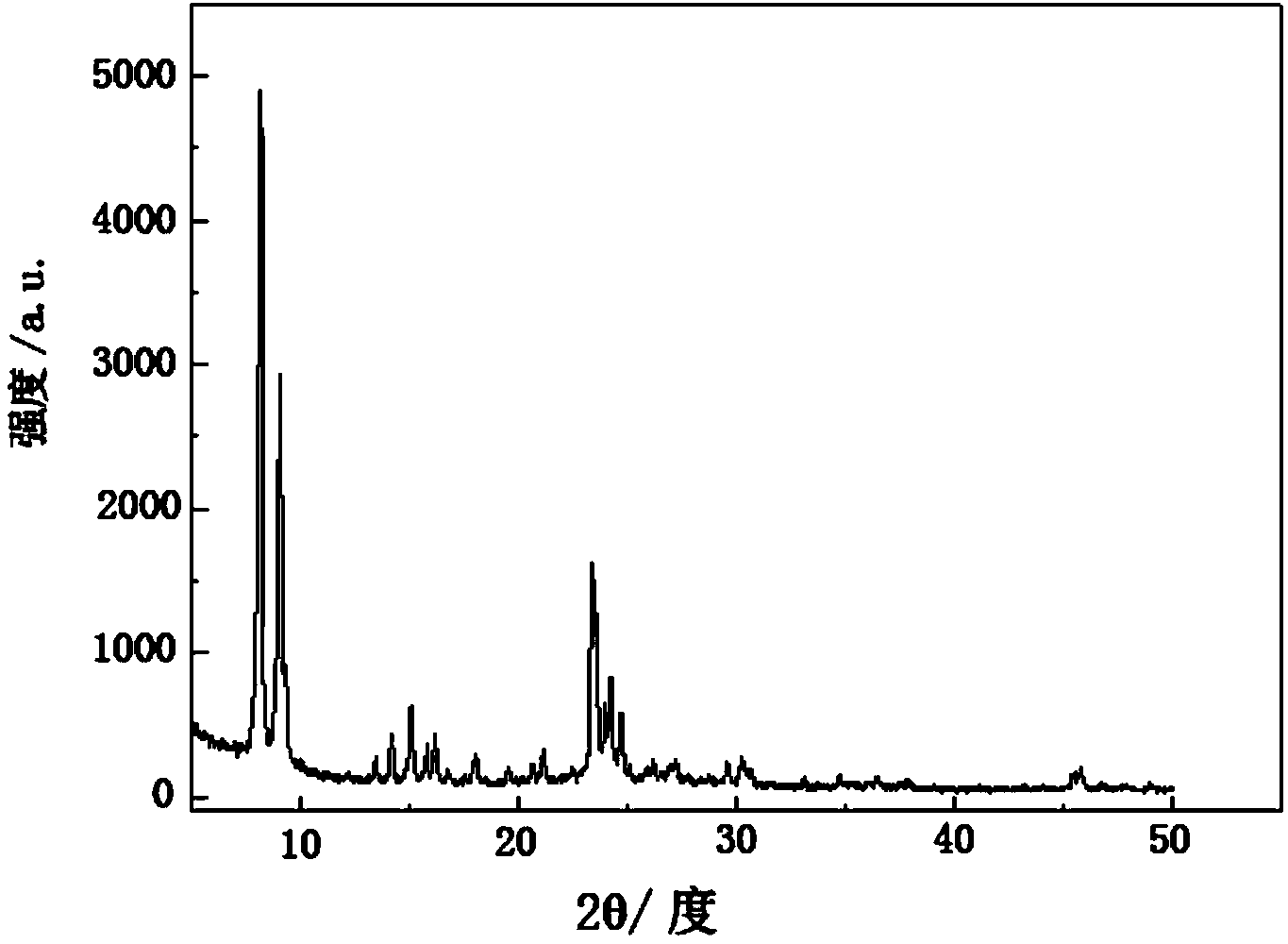

[0061] The hierarchical porous ZSM-5 / SiO prepared in this example 2 The XRD patterns and SEM patterns of the composite catalyst are as follows Figure 3a and Figure 3b shown.

[0062] Table 3 Cracking reaction main product yield distribution

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com