A combined method for diesel hydrotreating and upgrading

A technology of hydrogenation upgrading and diesel oil, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of excessive hydrogenation, large hydrogen consumption, unreasonable economy, etc., and reduce investment and hydrogen consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

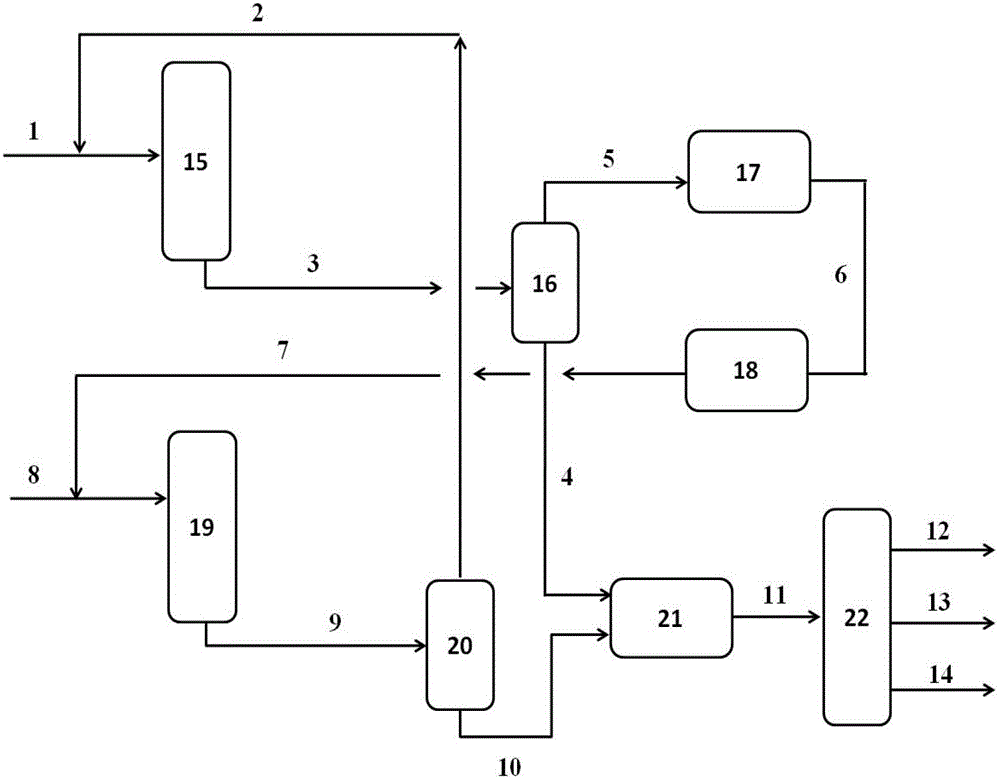

Method used

Image

Examples

Embodiment

[0020] Table 1 Main Properties of Raw Oil

[0021] project straight run diesel catalytic diesel Flow, 10,000 tons / year 120 80 Density (20℃) / g / ml 0.8556 0.9225 Distillation range, ℃ 180~340 180~350 Sulfur content, wt% 1.55 1.81 Aromatic content, wt% 22.1 58.6 cetane number 46 23

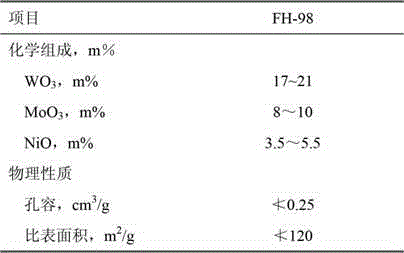

[0022] Table 2 Main Properties of Hydrofining Catalysts

[0023]

[0024] Table 3 embodiment process condition and reaction result

[0025] Process plan Reference scheme Example-1 Example-2 first reactor Raw oil Hybrid Diesel straight run diesel straight run diesel Hydrogen partial pressure, MPa 10.0 6.5 6.5 Hydrogen oil volume ratio 500:1 300:1 300:1 Airspeed, h -1 1.0 2.0 2.0 Reaction temperature, °C 360 340 350 second reactor Raw oil - catalytic diesel catalytic diesel Hydrogen parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com