Fermentation bacteria agent and fermentation method of excrements of livestock and poultry

A technology for fermentation inoculum and livestock and poultry manure, which is applied to the field of fermentation inoculum and fermentation of livestock and poultry manure, can solve the problems of complex fermentation operation, slow fermentation speed and high cost, and achieves simple operation, low cost and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

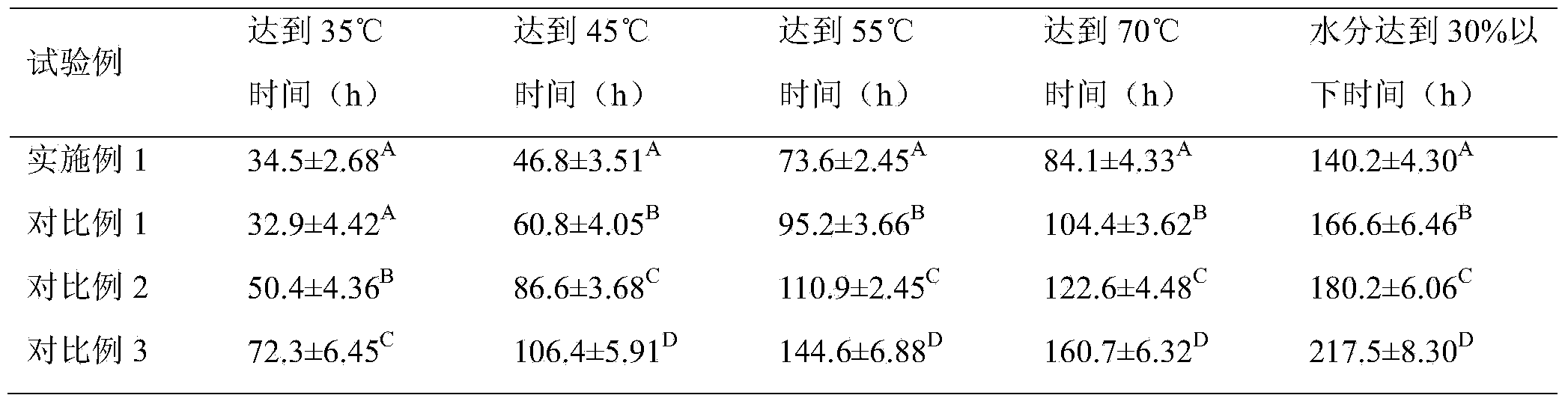

Embodiment 1

[0023] The live bacteria concentration in the bacterial liquid of the fermented bacterial agent is 2 billion / ml. Calculated as a percentage of the total number of live bacteria, the microorganisms in the bacterial solution are composed of 15% yeast, 35% lactic acid bacteria, and 50% bacillus. Add the fermenting agent diluted 10 times with water to the chicken manure with a water content of 40wt% according to the amount of 1 kg of fermenting agent per cubic meter and mix it well, then pile the chicken manure into a 50cm high manure pile and place it in a 15.6°C room. Environment. Then when the temperature of the manure heap reaches 40°C, turn the manure heap every 1 day for a total of 2 times, and cover it with dry sacks or coarse cloth after each turn. Finally, when the moisture in the dung heap is reduced to 30wt% and the temperature reaches 65°C, the fermentation process is completed to obtain the fermentation product organic fertilizer.

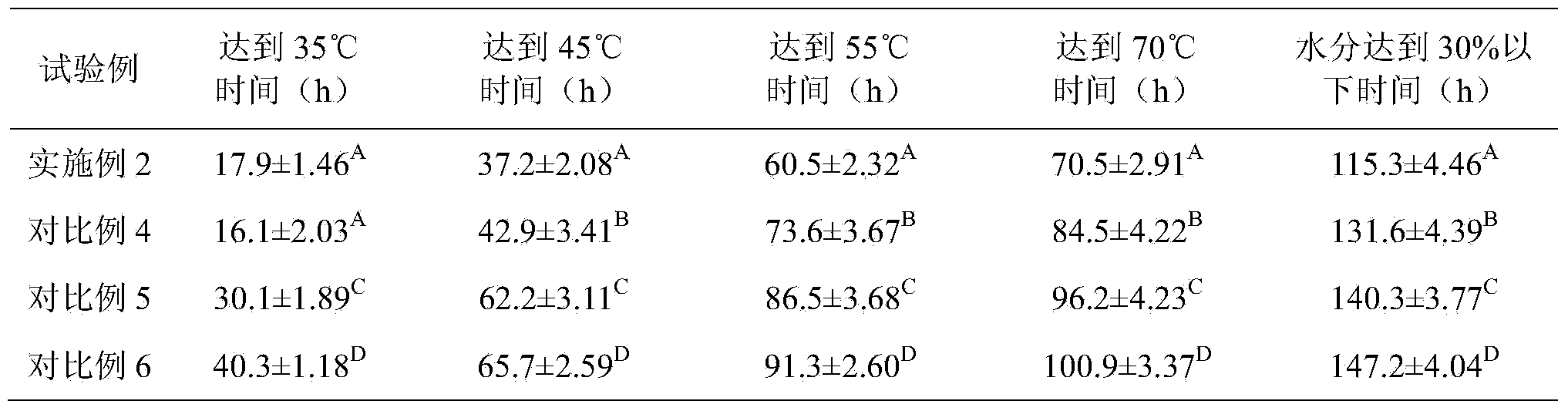

Embodiment 2

[0025] The viable bacteria concentration in the bacterial liquid of the fermented bacterial agent is 2.5 billion / ml. Calculated by the percentage of the total number of viable bacteria, the microorganisms in the bacterial solution are composed of 20% Brevibacterium, 30% Actinomycetes, and 50% Bacillus.

[0026] Add the fermented bacteria agent diluted 55 times with water to the chicken manure with a water content of 45wt% according to the amount of 1 kg of fermented agent per cubic meter and mix it thoroughly, then pile the chicken manure into a 60 cm high manure pile, and place it in a 24.5°C room. Environment. Then, when the temperature of the manure heap reaches 42.5°C, turn the manure heap every 1 day for a total of 3 times, and cover it with dry sacks or coarse cloth after each turn. Finally, when the moisture in the dung heap is reduced to 30wt% and the temperature reaches 67.5°C, the fermentation process is completed to obtain the fermentation product organic fertilize...

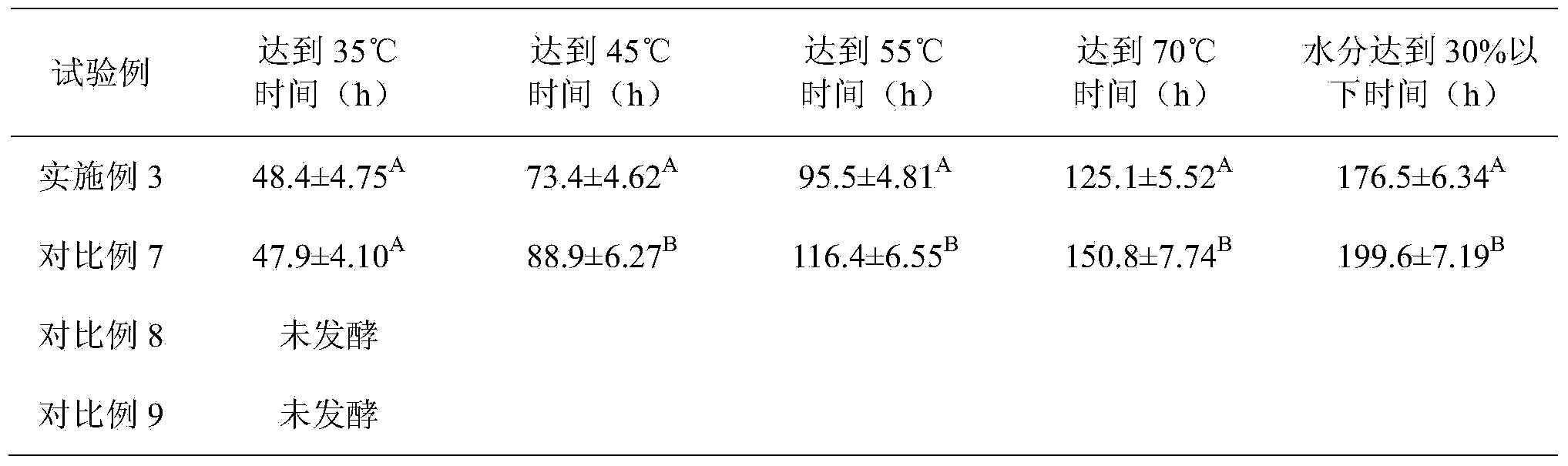

Embodiment 3

[0028] The viable bacteria concentration in the bacterial liquid of the fermented bacterial agent is 3 billion / ml. Calculated by the percentage of the total number of viable bacteria, the microorganisms in the bacterial solution are composed of 25% breviform bacteria, 30% lactic acid bacteria, and 45% nitrogen-fixing bacteria.

[0029] Add the fermenting agent diluted 100 times with water to the chicken manure with a water content of 50wt% according to the amount of 1 kg of fermenting agent per cubic meter and mix it thoroughly, then pile the chicken manure into a 80cm high manure pile and place it in a 4.9°C room. Environment. Then when the temperature of the manure heap reaches 45°C, turn the manure heap every 1 day for a total of 4 times, and cover it with dry sacks or coarse cloth after each turn. Finally, when the moisture in the dung heap is reduced to 30wt% and the temperature reaches 70°C, the fermentation process is completed to obtain the fermentation product organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com