Metal cleaning agent

A technology of metal cleaning agent and chelating agent, applied in the field of metal cleaning agent, can solve the problems of long cleaning time, affecting processing, and bodily injury of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] Preparation and application of artificial oil stains

[0081] Heat the mixture of industrial vaseline, 30# engine oil, and 20# engine oil to about 120°C to dissolve evenly, pour in lanolin, calcium-based fat, barium petroleum sulfonate and lanolin, stir to dissolve, control the temperature not to exceed 130°C, wait for After all dissolved, stop heating, add alumina powder, stir evenly, and cool to room temperature.

[0082]

[0083] Hang the polished and cleaned steel test piece (50×25×3~5mm) with a hook, dry it in an oven at 40°C for 30 minutes, cool it and weigh it to an accuracy of 0.2mg. Put the weighed test piece flat on a clean filter paper, use a small scraper to tweezer to pick up the artificial oil, and apply it evenly on two-thirds of one side of the test piece, leaving the remaining one-third surface uncoated. Wipe off excess oil on both sides and bottom of the test piece with filter paper. Oil stain coating should be controlled between 0.08~0.19g. Then h...

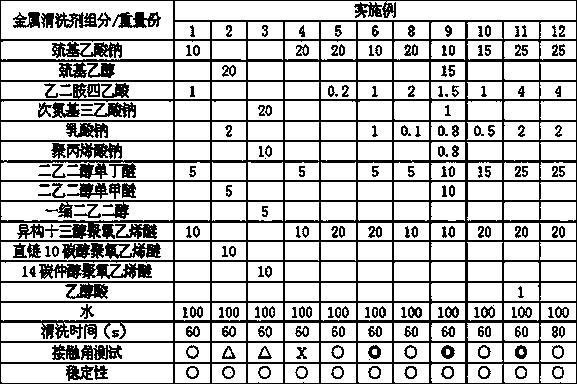

Embodiment 1-11)

[0098]

[0099] The present invention uses the traditional indoor static coupon (specification: 50mm×10mm×3mm, material is 20# steel) weight loss method to test the corrosion rate of the simulated corrosion solution. The main components of the simulated corrosion solution are NH4HS, NH4Cl and a small amount of H2S or NH3 etc. It is found that Examples 1-11 all have good corrosion inhibition effects.

[0100] The isomeric tridecyl alcohol polyoxyethylene ether in the embodiment is the 1307 product of Ningbo Lejia Chemical Co., Ltd., the straight-chain 10-carbon alcohol polyoxyethylene ether is the XP series product of BASF, and the 14-carbon secondary alcohol polyoxyethylene ether is Xuzhou Mei S-50 series products of Rui Chemical Co., Ltd.

[0101] After testing, the results of the metal cleaning agent mixed with mercapto-containing compounds, nitrogen-containing carboxylic acids and chelating agents with antioxidant effects to remove organic pollutants are all "excell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com