Industrial metallurgy dynamic model

A dynamic model and model technology, applied in teaching models, educational appliances, instruments, etc., can solve problems such as poor understanding, improve teaching quality, and disadvantages, and achieve the effects of intuitive teaching, improving teaching quality, and simplifying structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings.

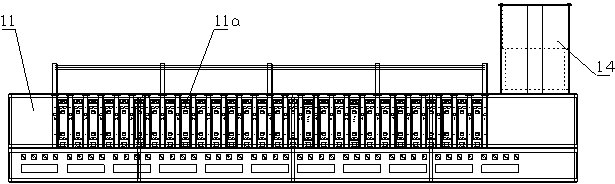

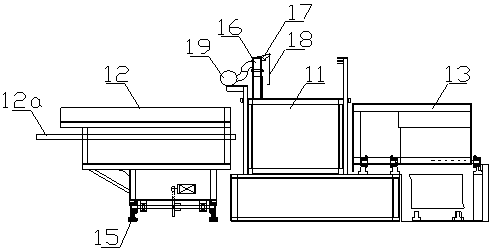

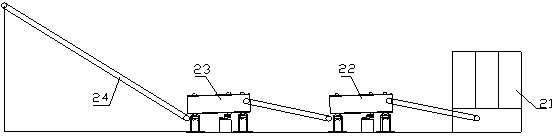

[0039] see Figure 1 to Figure 9 , an industrial metallurgical dynamic model made of metal materials, including a coking model system for simulating coal carbonization to produce coke, and a coking model system for simulating iron-containing raw materials mixed with coke and solvent and water to form spherical shapes and sintered into blocks The sintering model system for sintering, the blast furnace ironmaking model system for simulating the reaction of iron ore and reducing substances to obtain pig iron, the converter steelmaking model system for simulating molten iron, scrap steel and ferroalloy steelmaking in a converter, and the smelting model system for simulating refined A continuous casting model system for continuous casting of molten steel refined in a furnace into billets, and a rolling model system for simulating rotating rolls to change the shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com