Micrometer-scale glucose sensor microelectrode

A glucose sensor and microelectrode technology, which is applied in sensors, medical science, diagnosis, etc., can solve the problems of changing the test environment, rejection, large volume, etc., and achieve the effect of reducing human body rejection and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

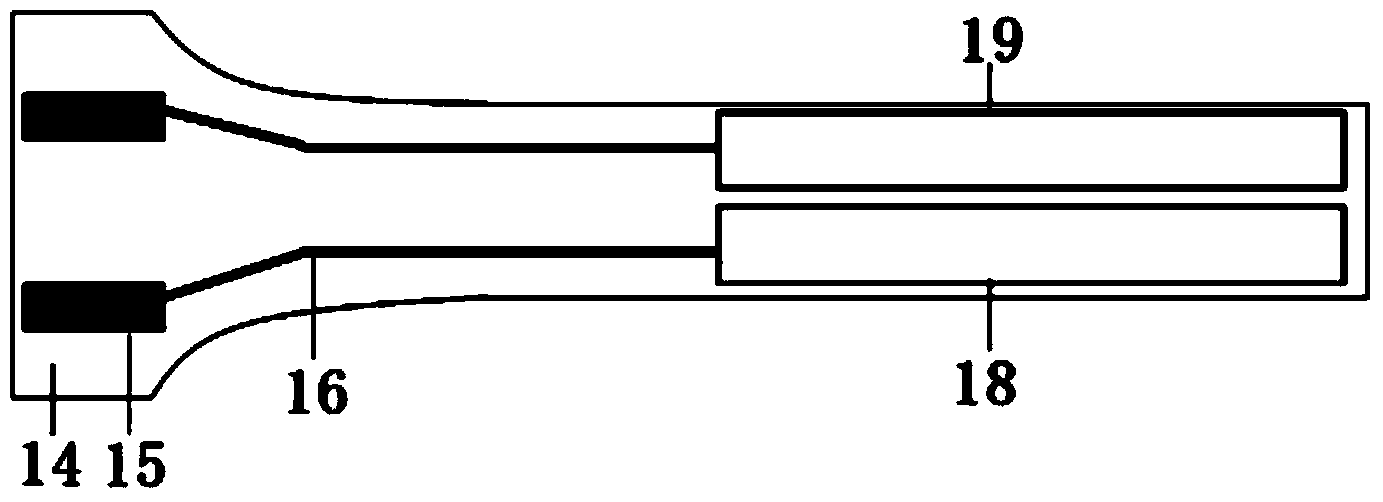

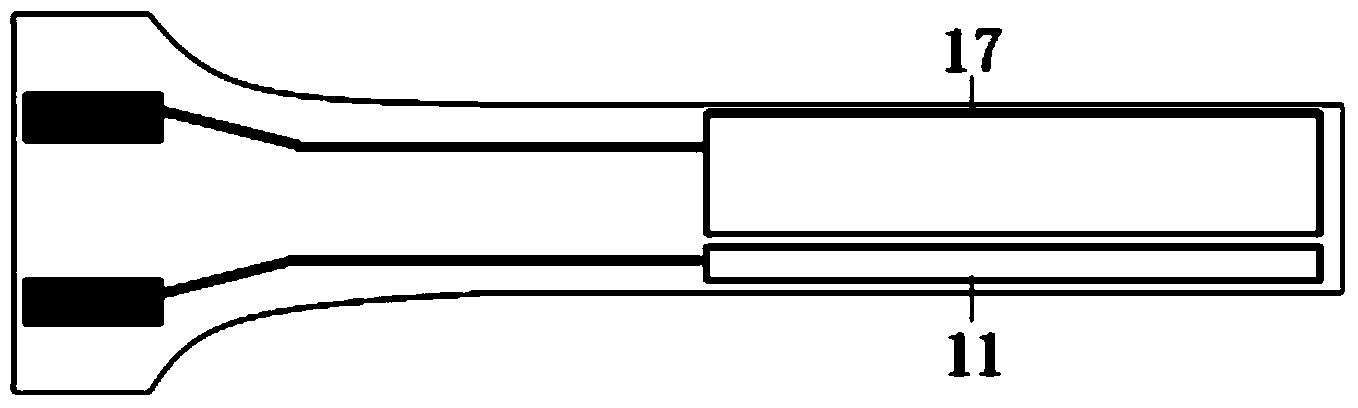

[0080] double-sided microelectrode

[0081] figure 1 and figure 2 For the double-sided microelectrode of the micrometer-scale glucose sensor microelectrode shown, the thickness of the substrate 14 is 0.01-0.8mm, each electrode is rectangular, the width of each electrode is 0.01-1mm, and the total length of the microelectrode is 0.5-8cm. The area is 0.1-2mm 2 , the counter electrode 17 and the reference electrode 11 are located on one surface of the substrate 14, the working electrode 18 and the auxiliary electrode 19 are located on the other surface of the substrate 14, and each electrode is connected to the gold PAD15 by a gold wire 16, and the PAD15 and each The electrodes are in one-to-one correspondence, the area of the counter electrode 17 is three times that of the reference electrode 11, and the area of the auxiliary electrode 19 and the working electrode 18 are equal.

Embodiment 2

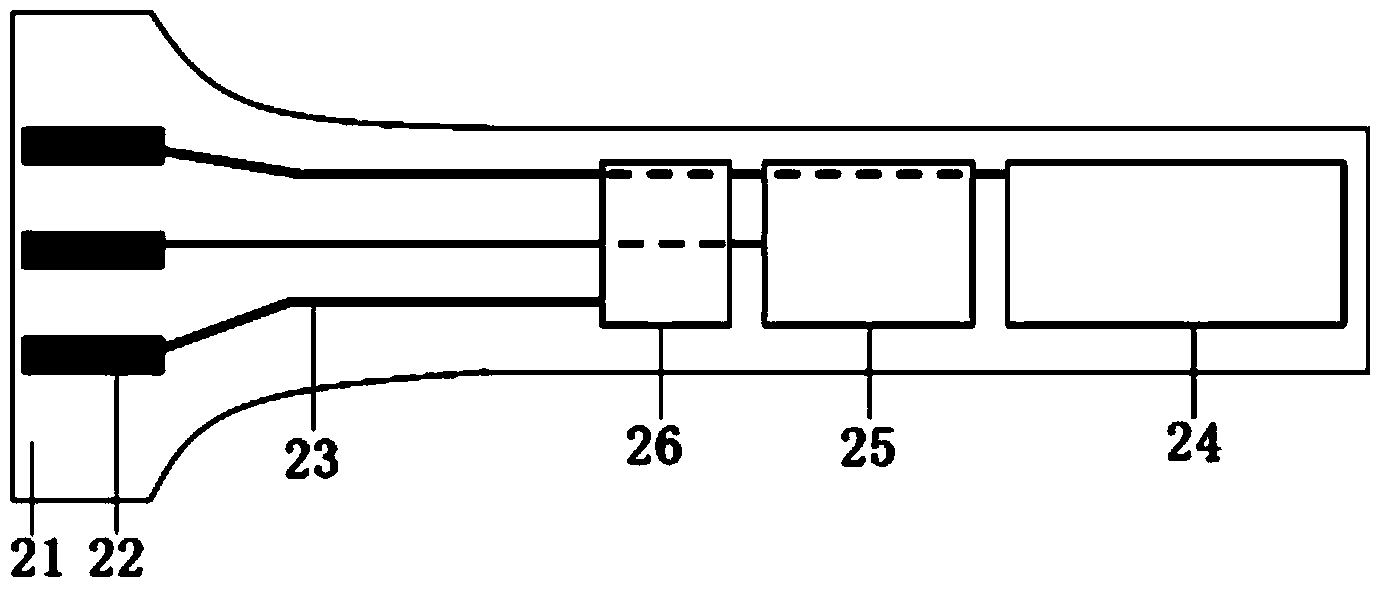

[0083] multilayer microelectrode

[0084] image 3 and Figure 4 In the multi-layer microelectrode of the micrometer-scale glucose sensor microelectrode shown, the substrate 21 is provided with a first insulating layer and a second insulating layer, and forms a ladder shape. The thicknesses of the substrate 21, the first insulating layer, and the second insulating layer are 0.01-0.8mm, each electrode is rectangular, the width of each electrode is 0.01-1mm, the total length of the microelectrode is 0.5-8cm, and the area of each electrode is 0.1-2mm 2 , the counter electrode 24, the working electrode 25 and the reference electrode 26 are respectively arranged on the base 21, the first insulating layer, and the second insulating layer of the ladder structure, and each electrode is connected to the gold PAD22 by the gold wire 23, and the PAD22 and the Each electrode corresponds to one by one.

Embodiment 3

[0086] ring microelectrode

[0087] Figure 5 The ring-shaped microelectrode of the micrometer-scale glucose sensor microelectrode shown, the front part of the base 27 is cylindrical, with a diameter of 0.1-1mm, the total length of the microelectrode is 0.5-8cm, and the area of each electrode is 0.1-10mm 2 , the counter electrode 30, the working electrode 31 and the reference electrode 32 are annularly distributed on the substrate 27, and each electrode is connected to the gold PAD28 through the gold wire 29 passing through the interior of the insulating substrate, and the PAD28 corresponds to each electrode one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com