Method for producing zirconium tetrachloride by carbochlorination and method for producing zirconium sponge

A technology of zirconium tetrachloride and chlorination furnace, which is applied in the direction of zirconium halide, etc., can solve the problems of large system pulse, cumbersome process flow, and high cost, and achieve the effects of continuous and stable reaction, short process flow, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

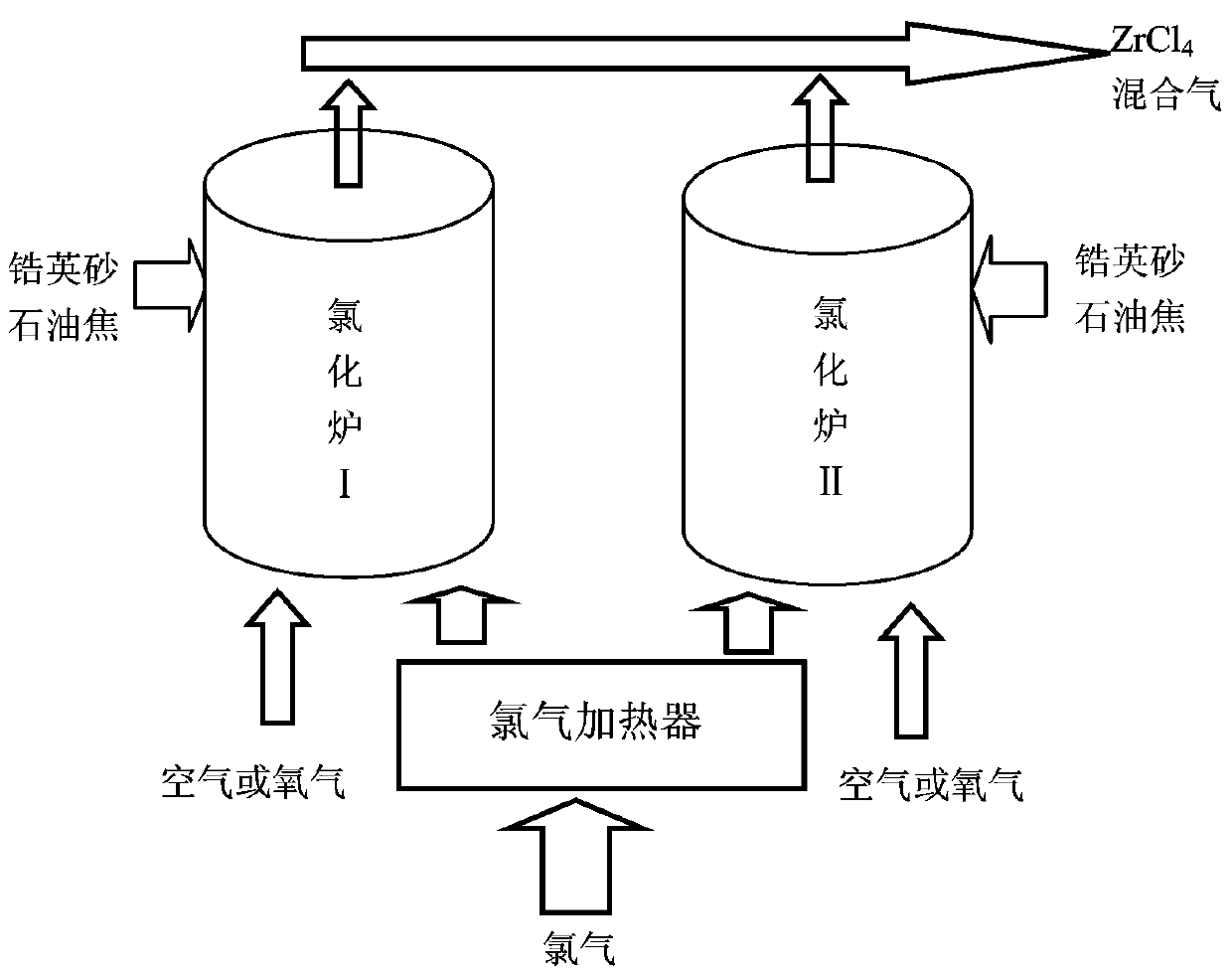

Method used

Image

Examples

example 1

[0032] 200-300 mesh zircon sand and 100-160 mesh petroleum coke are mixed according to the mass ratio of zircon sand to petroleum coke at 100:28 to form a mixture. Then, the mixture is added to the chlorination furnace to complete the feeding operation.

[0033] After feeding, preheat the solid mixture to 1230±10°C.

[0034] After completing the preheating, feed chlorine gas with a temperature of 1050±10°C into the chlorination furnace, so that the chlorine gas and the preheated mixture undergo a carbon boiling chlorination reaction, and maintain the reaction temperature at 1100±10°C to obtain A mixed gas mainly composed of zirconium tetrachloride.

example 2

[0036] Mix 300-400 mesh zircon sand and 100-160 mesh petroleum coke at a mass ratio of zircon sand to petroleum coke of 100:43 to form a mixture. Then, the mixture is added to the chlorination furnace to complete the feeding operation.

[0037] After the feeding is finished, air is introduced into the chlorination furnace to burn the petroleum coke in the mixture before the chlorination reaction, so that the solid mixture is preheated to 1450±10°C.

[0038] After preheating is completed, chlorine gas with a temperature of 550 ± 10°C is introduced into the chlorination furnace, so that the chlorine gas and the preheated mixture undergo a carbon boiling chlorination reaction, and the reaction temperature is maintained at 1070 ± 10°C to obtain A mixed gas mainly composed of zirconium tetrachloride.

example 3

[0040] 200-400 mesh zircon sand and 130-160 mesh petroleum coke are mixed according to the mass ratio of zircon sand to petroleum coke at 100:35 to form a mixture. Then, the mixture is added to the chlorination furnace to complete the feeding operation.

[0041] After the feeding is finished, air is introduced into the chlorination furnace to burn the petroleum coke in the mixture before the chlorination reaction, so that the solid mixture is preheated to 1350±10°C.

[0042] After completing the preheating, feed chlorine gas with a temperature of 800 ± 10°C into the chlorination furnace, so that the chlorine gas and the preheated mixture undergo a carbon boiling chlorination reaction, and maintain the reaction temperature at 1180 ± 10°C to obtain A mixed gas mainly composed of zirconium tetrachloride.

[0043] In summary, the beneficial effects of the present invention include the following aspects:

[0044] (1) It can directly chlorinate zircon sand, thus eliminating the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com