Cobalt molybdate hollow-ball powder material preparation method and cobalt molybdate hollow ball powder material

A technology of powder materials and hollow spheres, which is applied in the field of molybdate, can solve the problems of not having wrapping effect and limiting the excellent performance of cobalt molybdate micro-nano materials, and achieve excellent physical and chemical properties and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

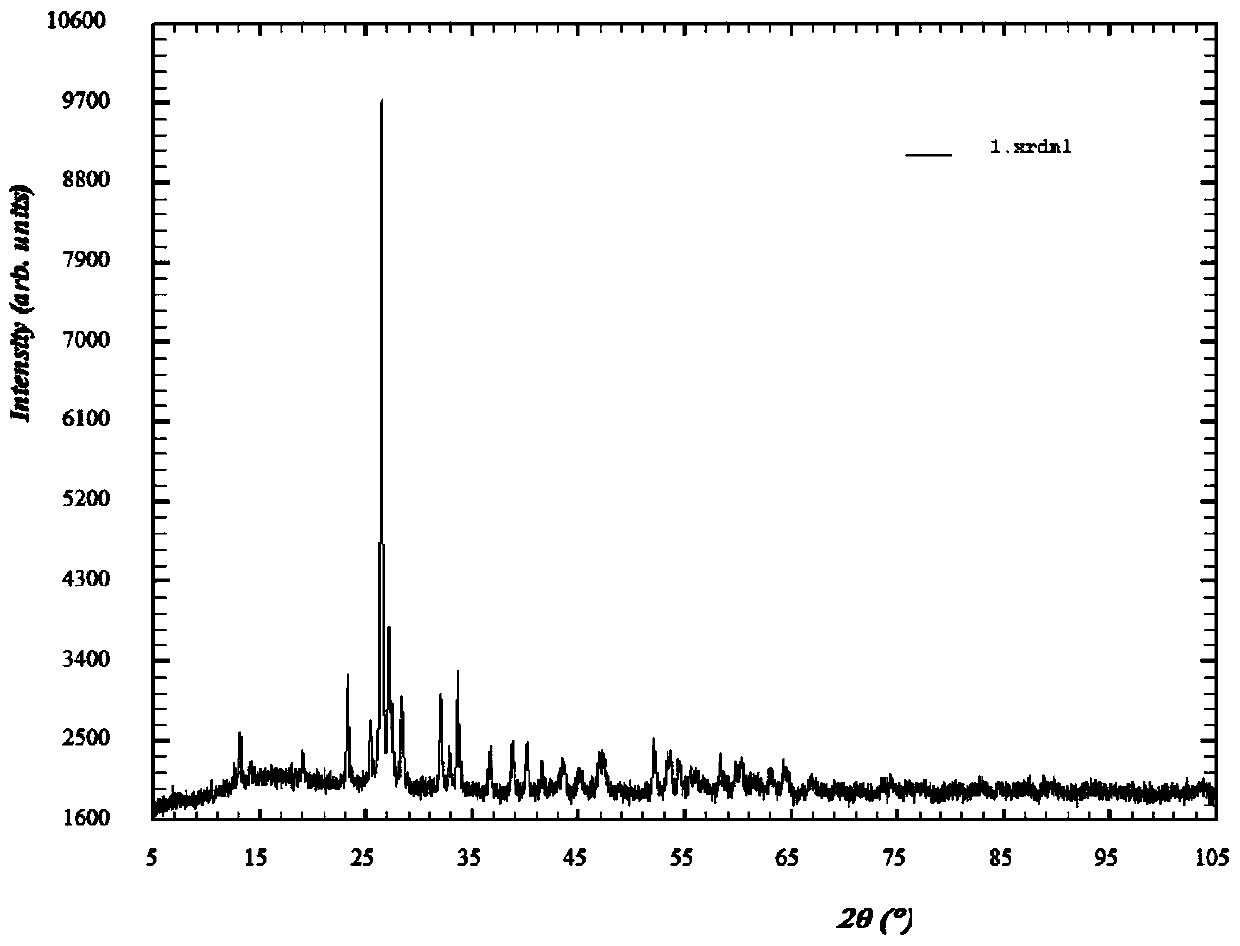

Embodiment 1

[0041]Weigh 250g of Angel yeast powder and add it to 15000ml of normal saline, fully stir with a magnetic stirrer at room temperature for 30min, then centrifuge at 3000r / m for 5min, discard the supernatant, disperse and wash with normal saline again, and centrifuge repeatedly. Carry out three times, then stir and dissolve the cleaned yeast with absolute ethanol, centrifuge at 3000r / m for 5min, discard the supernatant, and disperse and activate with absolute ethanol again, repeat this operation twice; Mix with deionized water, and add 1.25mol cobalt chloride hexahydrate to the mixture, so that the concentration of cobalt chloride hexahydrate is 0.083mol / L, stir at 50°C for 3 hours, so that the yeast cells can fully absorb cobalt ions; Then slowly add 1.25mol sodium molybdate dihydrate and deionized water to the system, adjust the concentration of sodium molybdate dihydrate in the system to 0.083mol / L, stir the above solution at 35°C with a magnetic stirrer until a large amount o...

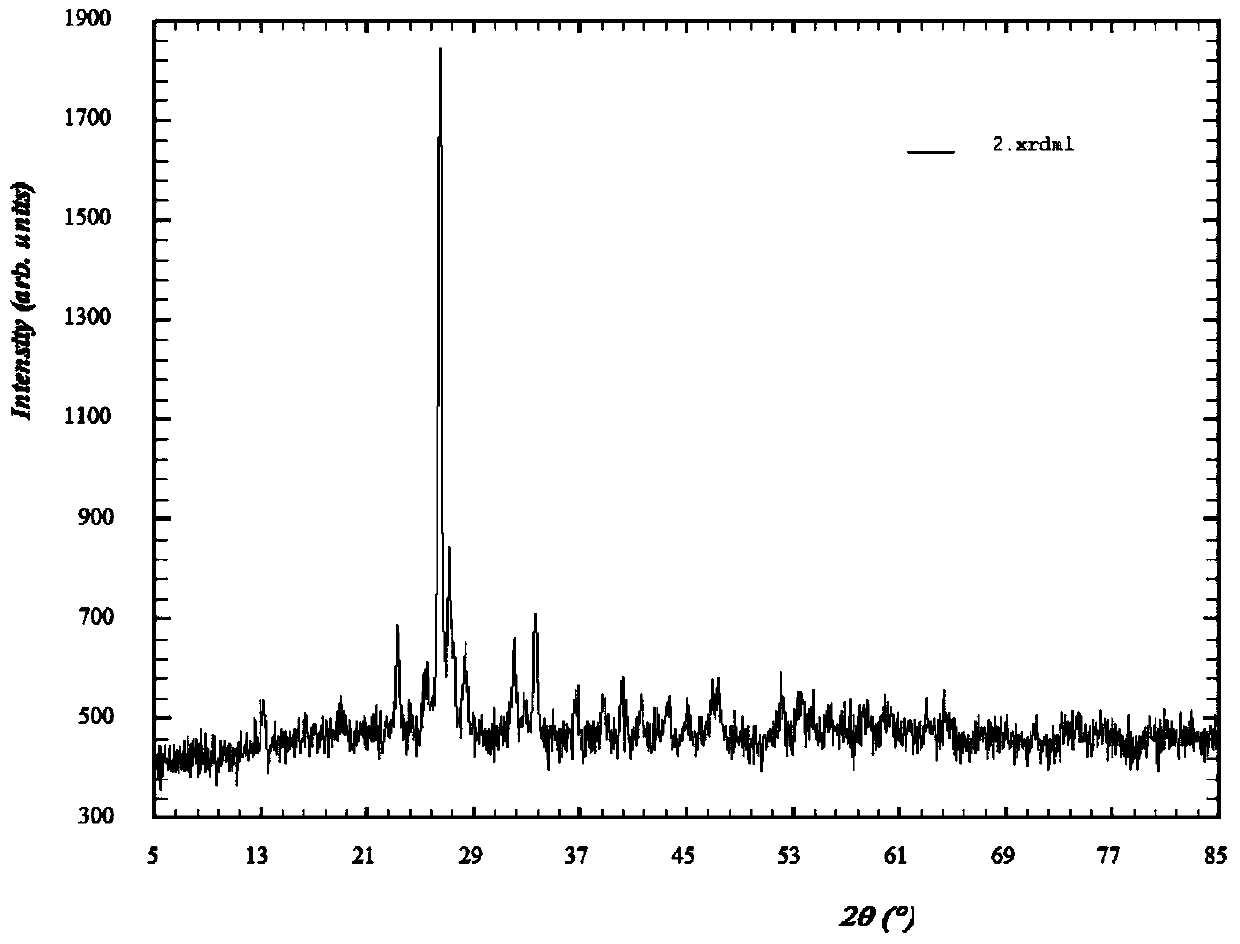

Embodiment 2

[0043] Weigh 500g of Angel Yeast Powder and add it into 30000ml of deionized water, fully stir with a magnetic stirrer at room temperature for 30min, then centrifuge at 3000r / m for 5min, discard the supernatant, disperse and wash with deionized water again, and then centrifuge. Repeat three times, then stir and dissolve the cleaned yeast with absolute ethanol, centrifuge at 3000r / m for 5min, discard the supernatant, disperse and activate with absolute ethanol again, repeat this operation twice; Mix the precipitate with deionized water, and add 2.5mol cobalt chloride hexahydrate to the mixture to make the concentration of cobalt chloride hexahydrate 0.083mol / L, stir at 50°C for 3 hours, so that the yeast cells can fully absorb cobalt ions ; Then slowly add 2.5mol sodium molybdate dihydrate and deionized water to the system, adjust the concentration of sodium molybdate dihydrate in the system to 0.083mol / L, stir the above solution at 40°C with a magnetic stirrer until a large amo...

Embodiment 3

[0045] Weigh 450g of Angel yeast powder and add it to 9000ml of normal saline, fully stir with a magnetic stirrer at room temperature for 30min, then centrifuge at 3000r / m for 5min, discard the supernatant, disperse and wash with normal saline again, and centrifuge repeatedly. Carry out three times, then stir and dissolve the cleaned yeast with absolute ethanol, centrifuge at 3000r / m for 5min, discard the supernatant, and disperse and activate with absolute ethanol again, repeat this operation twice; Mix with deionized water, and add 0.75mol cobalt chloride hexahydrate to the mixture, so that the concentration of cobalt chloride hexahydrate is 0.083mol / L, stir at 55°C for 2 hours, so that the yeast cells can fully absorb cobalt ions; Then slowly add 0.75mol sodium molybdate dihydrate and deionized water to the system, adjust the concentration of sodium molybdate dihydrate in the system to 0.083mol / L, stir the above solution at 45°C with a magnetic stirrer until a large amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com