Preparation method of water soluble polyester resin and its amino baking varnish

A polyester amino baking paint, water-soluble polyester technology, used in polyester coatings, coatings and other directions, can solve the problems of poor heat resistance, poor storage stability of water-based polyester, etc., to improve water resistance and good water resistance , the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of water-soluble polyester resin A1:

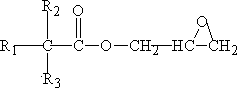

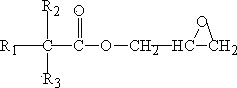

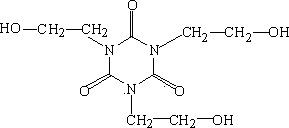

[0042] Add 235 g neopentyl glycol, 51 g trimethylolpropane, 29 g tris-hydroxyethyl isocyanurate, 59 g sodium-5-sulfonate isophthalate, 105 g isophthalic acid and 0.5 g butyltin triisooctoate In the reaction bottle, after 10--20 minutes of nitrogen gas, start to heat up; when the temperature rises to 120°C, the material melts and starts to stir; continue to heat up to 200°C, and keep reacting at this temperature until the material system becomes clear and the acid value Lower the temperature after it is less than 50mgKOH / g; when the temperature drops to 160°C, add 127g of adipic acid, 105g of isophthalic acid and 0.5g of butyltin triisooctoate, continue to heat up to 200°C, and keep at this temperature for reaction until After the acid value is 10mgKOH / g, cool down; when the temperature drops to 170°C, add 58g of glycidyl tert-carbonate (E-10P) and react at this temperature until the acid value is less than 2mgKOH / g, the...

Embodiment 2

[0044] Preparation of water-soluble polyester resin A2:

[0045] Add 235 g neopentyl glycol, 51 g trimethylolpropane, 29 g trishydroxyethyl isocyanurate, 20 g sodium 5-sulfonate isophthalate, 115 g isophthalic acid and 0.5 g butyltin triisooctoate In the reaction bottle, after 10--20 minutes of nitrogen gas, start to heat up; when the temperature rises to 120°C, the material melts and starts to stir; continue to heat up to 200°C, and keep reacting at this temperature until the material system becomes clear and the acid value Lower the temperature after less than 50mgKOH / g; when the temperature drops to 160°C, add 127g of adipic acid, 115g of isophthalic acid and 0.5g of butyltin triisooctoate, continue to heat up to 200°C, and keep at this temperature for the reaction until After the acid value is 10mgKOH / g, cool down; when the temperature drops to 170°C, add 58g of glycidyl tert-carbonate (E-10P) and react at this temperature until the acid value is less than 2mgKOH / g, then c...

Embodiment 3

[0047] Preparation of water-soluble polyester resin A3:

[0048] Add 235g of neopentyl glycol, 51g of trimethylolpropane, 21g of isophthalic acid-5-sodium sulfonate, 118g of isophthalic acid and 0.5g of butyltin triisooctanoate into the reaction flask, and pass nitrogen gas for 10--20min. , start to heat up; when the temperature rises to 120°C, the material melts and starts to stir; continue to heat up to 200°C, and keep it at this temperature for reaction until the material system becomes clear and the acid value is less than 50mgKOH / g, then cool down; when the temperature drops to At 160°C, add 127g of adipic acid, 118g of isophthalic acid and 0.5g of butyltin triisooctoate, continue to heat up to 200°C, and keep reacting at this temperature until the acid value is 10mgKOH / g, then cool down; cool down to At 150°C, add 200g of ethylene glycol butyl ether to obtain water-soluble polyester resin A3. The water-soluble polyester resin is a transparent viscous liquid, its solid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com