Biological extracting and purifying method for beer yeast soluble 1,3-beta-D-glucan

A technology of brewer's yeast and purification method, applied in the field of glucan, can solve the problems such as the lack of continuity in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

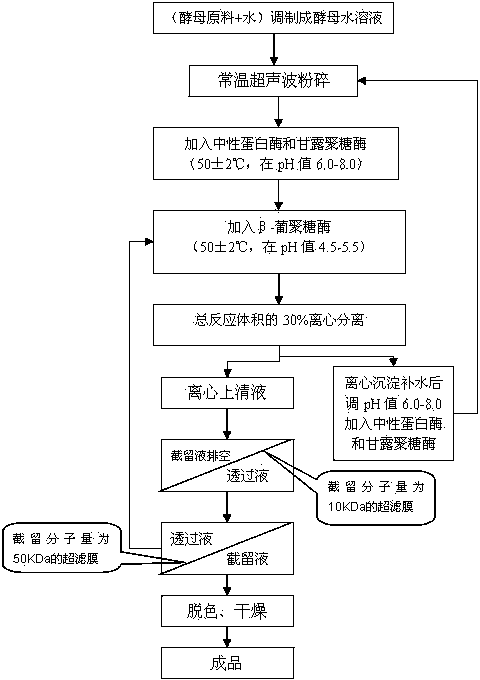

Method used

Image

Examples

Embodiment 1

[0045]Step 1: Take 120g of fresh yeast sludge from the bottom of the fermenter, wash it repeatedly with excess distilled water, and centrifuge at 4000 rpm for 20 minutes until the supernatant is colorless and clear, and no sugar can be detected by the phenol-sulfuric acid method;

[0046] Step 2: Add water to 5L, the solid content is 2%, stir, put the ultrasonic generator of the ultrasonic cell pulverizer into the mixed solution, the ultrasonic power is 400W, the working time is 5 seconds, the interval time is 10 seconds, and the total ultrasonic time is 20 minutes , to break the wall;

[0047] Step 3: Continue to replenish 5L of water for dilution, adjust the pH value to 6.0, boil and cool to 48°C, add mannanase at 0.5% of the dry weight of yeast, add neutral protease at 200U / g, and react for 24 hours;

[0048] Step 4: Adjust the pH to 5.0, add β-glucanase at 0.5% of the dry weight of the yeast, take 30% after 4 hours of reaction, centrifuge, collect the supernatant, return t...

Embodiment 2

[0052] Step 1: Take 535g of fresh yeast sludge from the bottom of the fermenter, wash it repeatedly with excess distilled water, centrifuge at 4000 rpm for 20 minutes, until the supernatant is colorless and clear, and no sugar can be detected by the phenol-sulfuric acid method;

[0053] Step 2: Add water to 5L, the solid content is 9%, stir, put the ultrasonic generator of the ultrasonic cell pulverizer into the mixed liquid, the ultrasonic power is 500W, the working time is 7 seconds, the interval time is 10 seconds, and the total ultrasonic time is 25 minutes , to break the wall;

[0054] Step 3: Continue to replenish 5L of water for dilution, adjust the pH value to 7.0, boil and cool to 50°C, add mannanase at 1% of the dry weight of yeast, add neutral protease at 210U / g, and react for 26 hours;

[0055] Step 4: Adjust the pH to 5.0, add β-glucanase according to 1% of the dry weight of the yeast, take 30% after 4 hours of reaction, centrifuge, collect the supernatant, return...

Embodiment 3

[0059] Step 1: Take 890g of fresh yeast sludge from the bottom of the fermenter, with a solid content of 15.84%, wash repeatedly with excess distilled water, and centrifuge at 4000 rpm for 20 minutes until the supernatant is colorless and clear, and no sugar can be detected by the phenol-sulfuric acid method ;

[0060] Step 2: Add water to 5L, make the solid content 15%, stir, put the ultrasonic generator of the ultrasonic cell pulverizer into the mixed liquid, ultrasonic power 600W, working time 10 seconds, interval time 10 seconds, total ultrasonic time 30 minutes , to break the wall;

[0061] Step 3: Continue to replenish 5L of water for dilution, adjust the pH value to 8.0, boil and cool to 52°C, add mannanase at 1.5% of the dry weight of yeast, add neutral protease at 250U / g, and react for 28 hours;

[0062] Step 4: Adjust the pH to 5.0, add β-glucanase at 1.5% of the dry weight of the yeast, take 30% after 4 hours of reaction, centrifuge, collect the supernatant, return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com